A kind of multifunctional nanofiber-based composite hemostatic patch and preparation method thereof

A technology of nanofibers and nanofiber membranes, which is applied in the field of medical supplies, can solve problems such as single function of hemostatic patches, poor mechanical strength of nanofiber membranes, re-infection of wounds, etc., achieve excellent healing effect, outstanding hemostatic and anti-inflammatory performance, and prolong The effect of changing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of oxidized dandelion fluff powder: take dandelion fluff and immerse in 3wt% sodium periodate solution for treatment, wash with deionized water, freeze-dry and pulverize to obtain nanoscale oxidized dandelion fluff powder (O-PR);

[0035] Preparation of activated dandelion fluff powder: get dandelion fluff and immerse it in 0.5mol / L sodium bicarbonate solution for treatment, wash with deionized water until the washing liquid is neutral, then freeze-dry and pulverize to obtain nanoscale activated dandelion fluff powder (H- PR);

[0036] Preparation of oxidized dandelion leaf fiber powder: extract dandelion fiber from dandelion leaves, immerse the extracted dandelion leaf fiber in 3wt% sodium periodate solution for treatment, wash with deionized water, freeze-dry and pulverize to obtain nanoscale oxidized dandelion Leaf fiber powder (O-PF);

[0037] Preparation of genipin / ovalbumin solution: disperse the ovalbumin in deionized water and stir evenly under ultr...

Embodiment 2

[0041] Preparation of nanofibrous membranes

[0042] (1) Get the polyvinyl alcohol solution prepared in Example 1, for subsequent use;

[0043](2) Get the oxidized sodium alginate solution prepared in Example 1 for subsequent use;

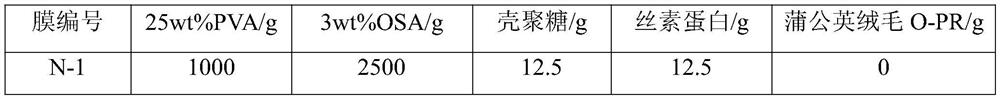

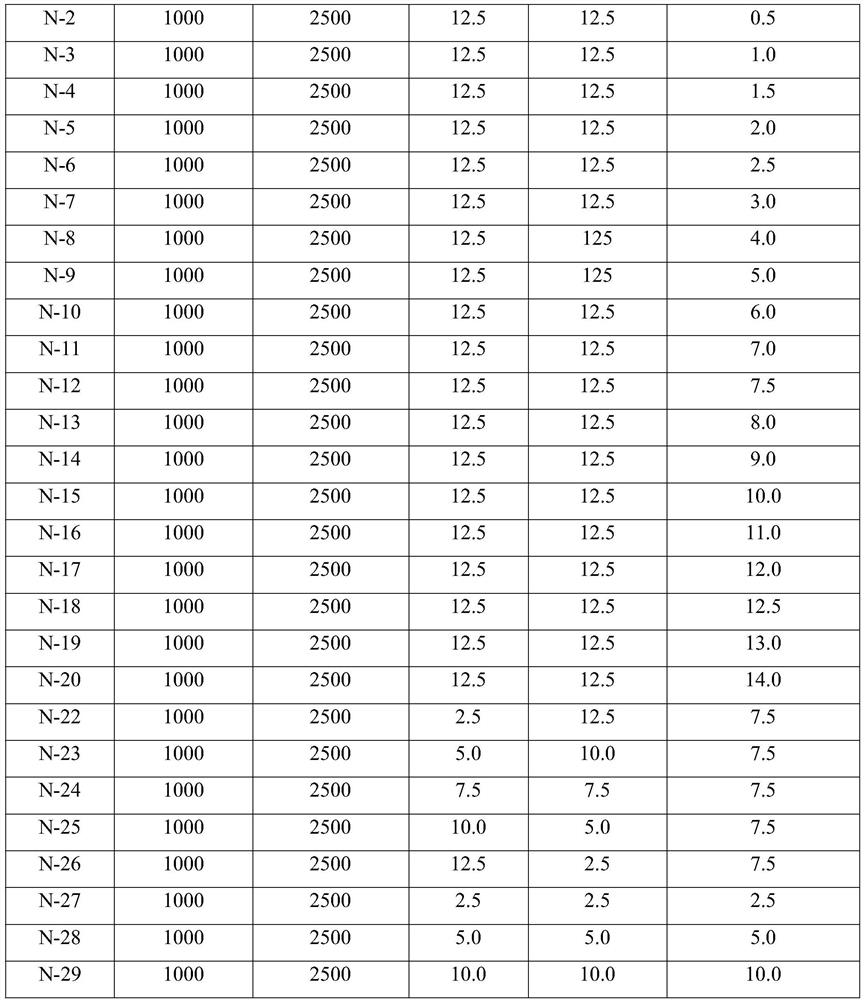

[0044] (3) Disperse chitosan (85% degree of deacetylation) in the oxidized sodium alginate solution and stir for reaction, then add polyvinyl alcohol solution to obtain a mixed solution, and add oxidized dandelion fluff powder O-PR ( Prepared in Example 1) after stirring evenly, add silk fibroin to it, and stir evenly to obtain spinning stock solution;

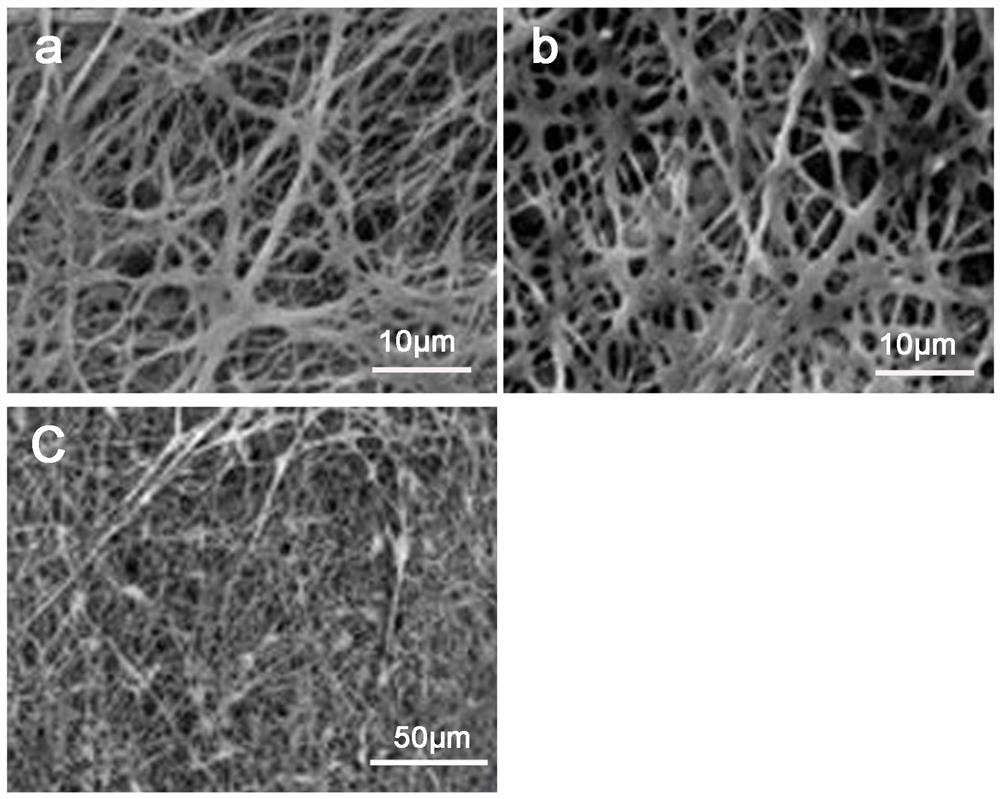

[0045] (4) The spinning stock solution is electrospun to obtain a nanofiber membrane, and the nanofiber membrane is peeled off and soaked in a genipin / ovalbumin solution (the weight ratio of genipin to ovalbumin solution is 0.3:1000). After the joint reaction, the nanofiber membrane is obtained by freeze-drying and sterilizing; the spinning conditions are as follows: the spinning voltage is 16-20...

Embodiment 3

[0057] Preparation of nanofibrous membranes

[0058] (1) Get the 20wt% polyvinyl alcohol solution prepared in 1250g embodiment 1, for subsequent use;

[0059] (2) get 1875g embodiment 1 preparation 4wt% oxidized sodium alginate solution, standby;

[0060] (3) After dispersing 12.5g chitosan (deacetylation degree 85%) in the oxidized sodium alginate solution and stirring for reaction, the above mixed solution was added into the polyvinyl alcohol solution, and then 7.5g oxidized dandelion fluff powder was added thereto Body O-PR (prepared in Example 1) was stirred evenly to obtain a mixed solution, and 12.5 g of silk fibroin was added to the mixed solution, and the spinning stock solution was obtained after being stirred evenly;

[0061] (4) The spinning stock solution is electrospun to obtain a nanofiber membrane, and the nanofiber membrane is peeled off and soaked in a genipin / ovalbumin solution (the weight ratio of genipin to ovalbumin solution is 0.3:1000). After the joint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com