Directionally driven targeted hemostasis micromotor and preparation method thereof

A micro-motor and targeted technology, applied in the fields of pharmaceutical formulations, applications, and pharmaceutical sciences, can solve the problems of wound limitation of application, limitation of coagulation function of hemostatic agents, and difficulty in controlling blood loss, etc., and achieves high surface potential and good biological phase. Capacitive, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

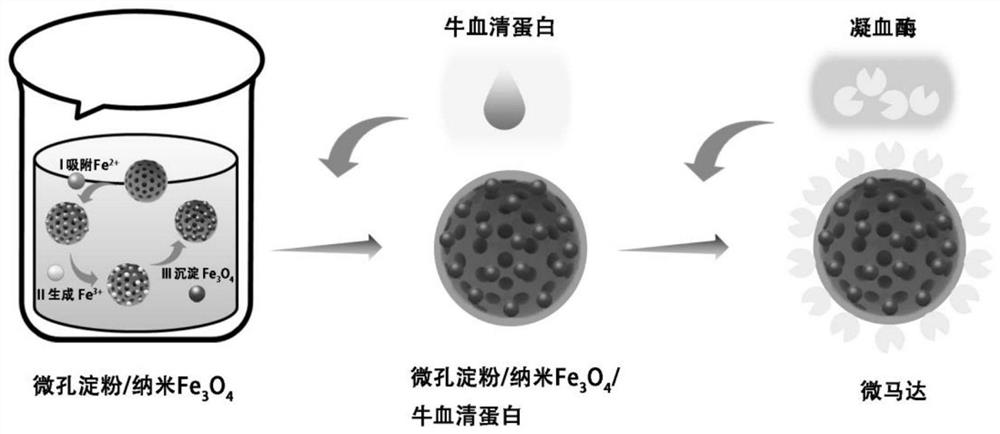

[0041] The present invention is directed to driving the preparation method of targeting the hemostatic micromotor, the preparation process is figure 1 As shown, including the following steps:

[0042] Step a) Nano Fe 3 O 4 Self-assembly on micro-pore starch:

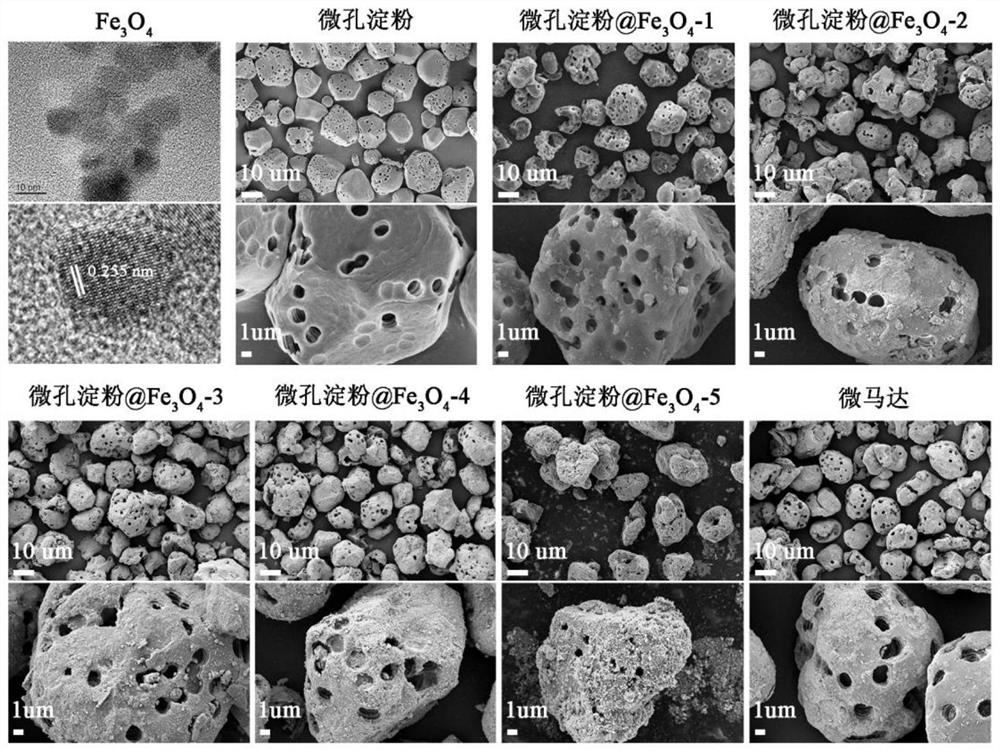

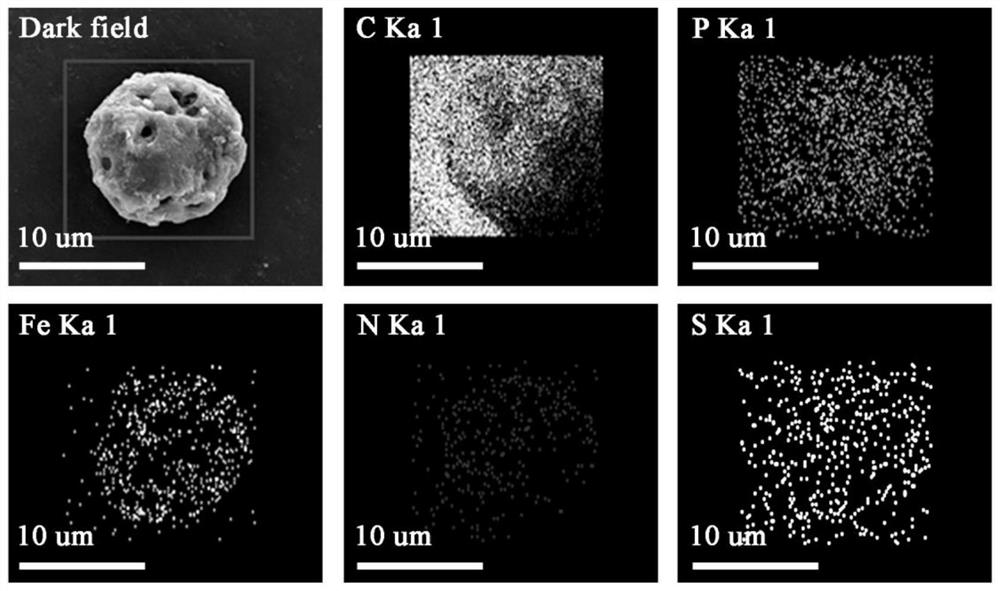

[0043] 0.48 g of micro-pure starch was added to aqueous methane trimethylammonium bromide, and the mass ratio of microporous starch and tetraalkyl trimethylammonium bromide was 0.01: 160-1: 160w / v, at 40-70 EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc. 2 The mixture was added to 50-500 μl of the solution, stirred for 5-60min, and sufficiently adsorbing the microporous starch. 2+ Then, the concentration of 0.007 mol / 5ml was added dropwise. 2 O 2 25-300 μL of solution, oxidized portion Fe 2+ After 5-10 min, aqueous NaOH aqueous solution or ammonia was added dropwise until pH = 8-10, resulting in a precipitated microporous starch / nanometer Fe. 3 O 4 -1 particles; synthetic particles with 75% alcohol thorns, then stand for 1-10 min, ...

Embodiment 2

[0056] The preparation method of the present invention is directed to the preparation of the hemostatic micromotactic hemostasis, the operation steps are as follows:

[0057] a) Nano Fe 3 O 4 Self-assembly on microporous starch

[0058] 0.48 g of micro-pore starch was added to aqueous cencetaxyl trimethylammonium bromide (0.01: 160, w / v) aqueous solution, and nitrogen gas was 10 min at 60 ° C to exclude air. 400μL FeCl 2 Solution (0.01 mol / 5 mLHCl solution (0.01 mol / 5 mL)) was added to the above mixture for 20 min, and the microporous starch was sufficiently adsorbed. 2+ . Then, quickly drop H. 2 O 2 (0.007 mol / 5mL) solution, oxidized part of Fe 2+ . After 5 min, NaOH (1 ml, 0.056 g / ml) aqueous solution was dripped until pH = 9, and finally the precipitated microporous starch / nanometer Fe 3 O 4 -1 particles. Synthetic microporous starch / nanometer Fe 3 O 4 -1 particles with 75% alcohol thorns to wash, then stand for 5 min, remove excess chemical reagents and free Fe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com