MEMS absolute pressure sensor and processing method thereof

A pressure sensor and absolute pressure technology, which is applied in the field of MEMS micromachining and manufacturing, can solve problems such as long-term stability to be verified, expensive technology, and air leakage, so as to avoid vacuum failure or long-term micro-air leakage, simplify the process flow, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes the present invention in detail, and the features and advantages of the present invention will become more clear and definite along with these descriptions.

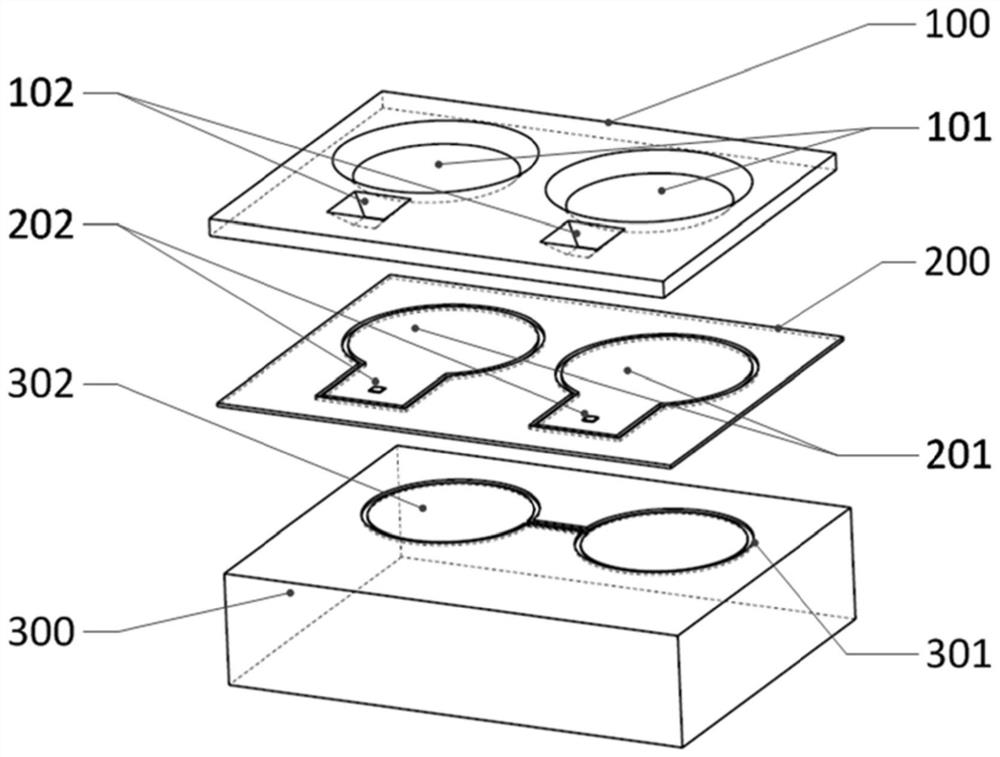

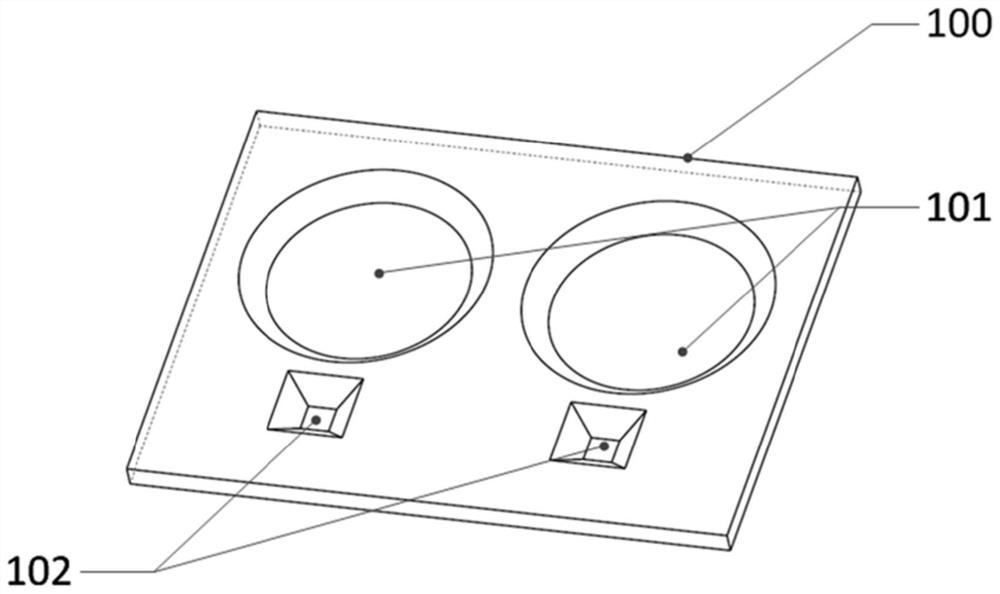

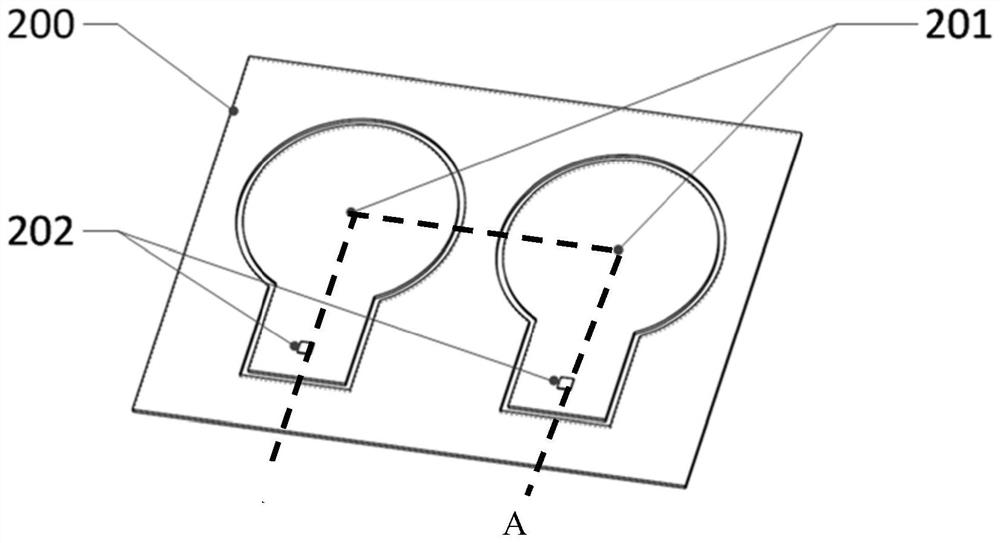

[0037] According to the first aspect of the present invention, such as figure 1 As shown, a MEMS absolute pressure sensor is provided, including a glass cover plate 100, a silicon pressure sensitive film 200 and a glass substrate 300; one side of the silicon pressure sensitive film 200 is anodically bonded to the glass substrate 300, and Two connected vacuum reference chambers are formed, and the other side of the silicon pressure-sensitive film 200 is anodically bonded to the glass cover plate 100 to form two independent open gas pressure-sensing structures. The two connected vacuum reference chambers are connected to two independent The open gas pressure-sensing structure corresponds to the upper and lower sides, and the two connected vacuum reference chambers and the silicon pressure-sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com