Preparation method of copper oxide with nano flower-like structure

A technology of copper oxide and nanoflowers, which is applied in the field of nanomaterials, can solve the problems of cumbersome and time-consuming steps of nanoflower-shaped copper oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing copper oxide with a nano-flower structure, comprising the steps of:

[0049] Soak foamed copper with an area of 2cm×2cm in 20ml of a mixed solution containing 2.5mol / l sodium hydroxide and 0.2mol / l ammonium persulfate, react for 10 minutes, wash with water repeatedly after the reaction, and place in a 60°C oven Dry to obtain copper oxide.

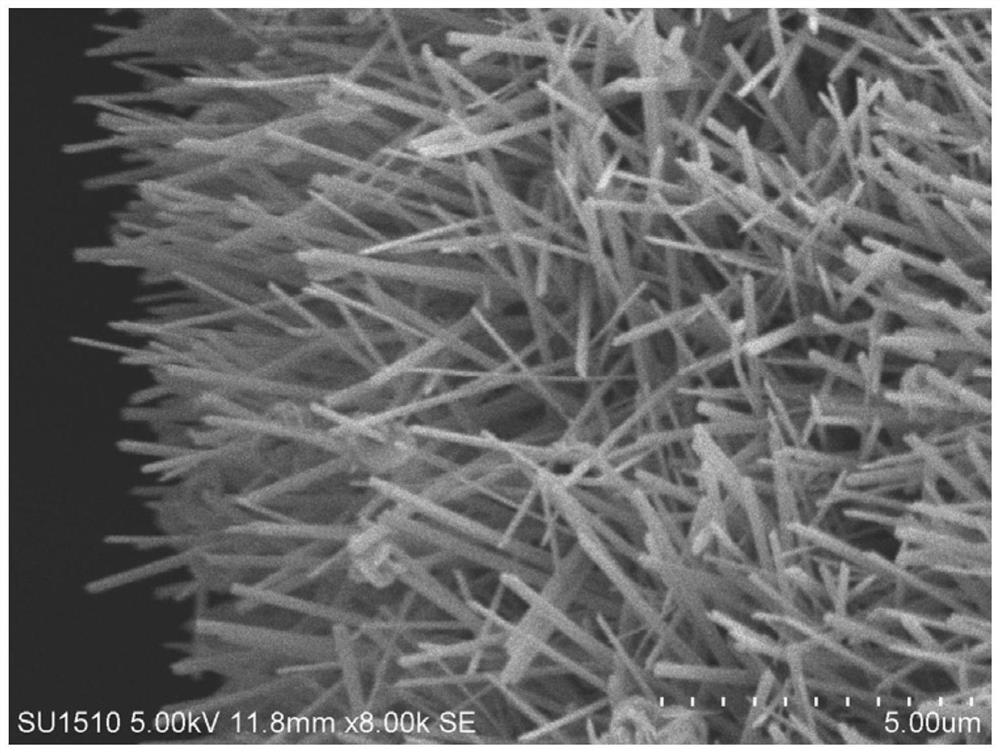

[0050] figure 1 To analyze the morphology of the copper oxide in Example 1 by a Hitachi su1510 scanning electron microscope. Depend on figure 1 As shown, copper oxide nanowires are formed at this time, the length of which is between 1 μm and 5 μm, and the diameter is approximately between 100 and 500 nm.

[0051] A 5 μL water drop was dropped on the copper oxide surface prepared in Example 1 by a contact angle measuring instrument, and the static water contact angle was 0°.

Embodiment 2

[0053] A method for preparing copper oxide with a nano-flower structure, comprising the steps of:

[0054] Soak foam copper with an area of 2cm×2cm in 20ml of a mixed solution containing 2.5mol / l sodium hydroxide and 0.2mol / l ammonium persulfate, react for 20 minutes, wash with water repeatedly after the reaction, and place in an oven at 60°C Dry to obtain copper oxide.

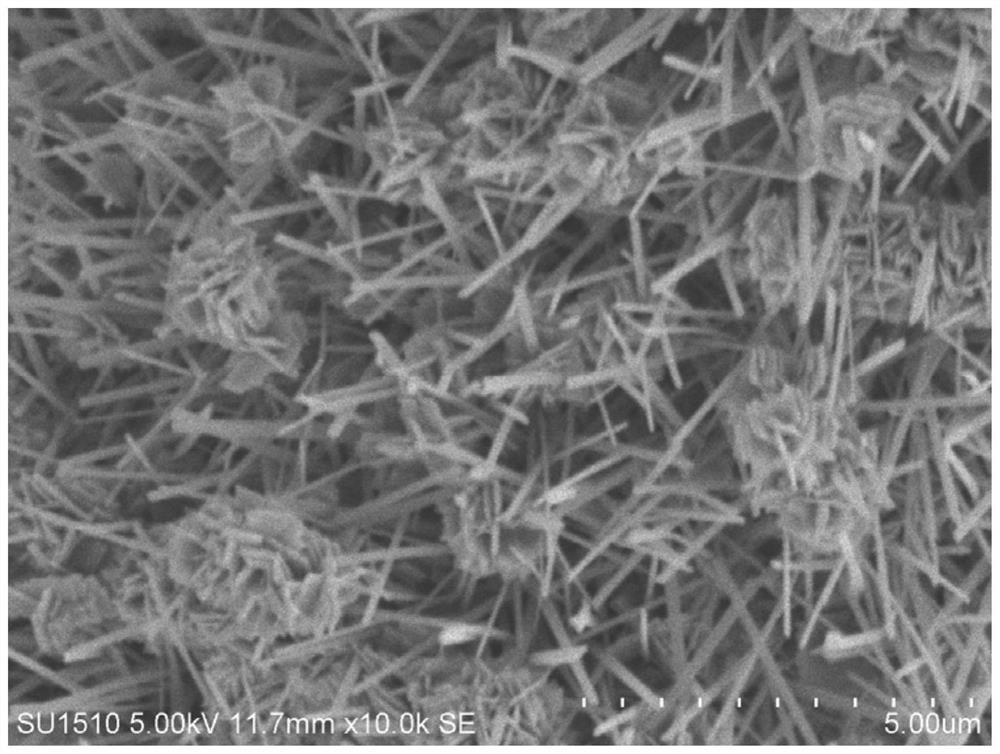

[0055] figure 2 To analyze the morphology of the copper oxide in Example 2 by a Hitachi su1510 scanning electron microscope. Depend on figure 2 As shown, a nanowire-nanosheet copper oxide is formed at this time, wherein the length of the nanowire is between 1 μm and 5 μm, the diameter is between 100 and 500 nm, and the diameter of the nanosheet is between 1 μm and 3 μm.

[0056] A 5 μL water drop was dropped on the copper oxide surface prepared in Example 2 by a contact angle measuring instrument, and the static water contact angle was 0°.

Embodiment 3

[0058] A method for preparing copper oxide with a nano-flower structure, comprising the steps of:

[0059] Soak foam copper with an area of 2cm×2cm in 20ml of a mixed solution containing 2.5mol / l sodium hydroxide and 0.2mol / l ammonium persulfate, react for 30 minutes, wash with water repeatedly after the reaction, and place in an oven at 60°C Dry to obtain copper oxide.

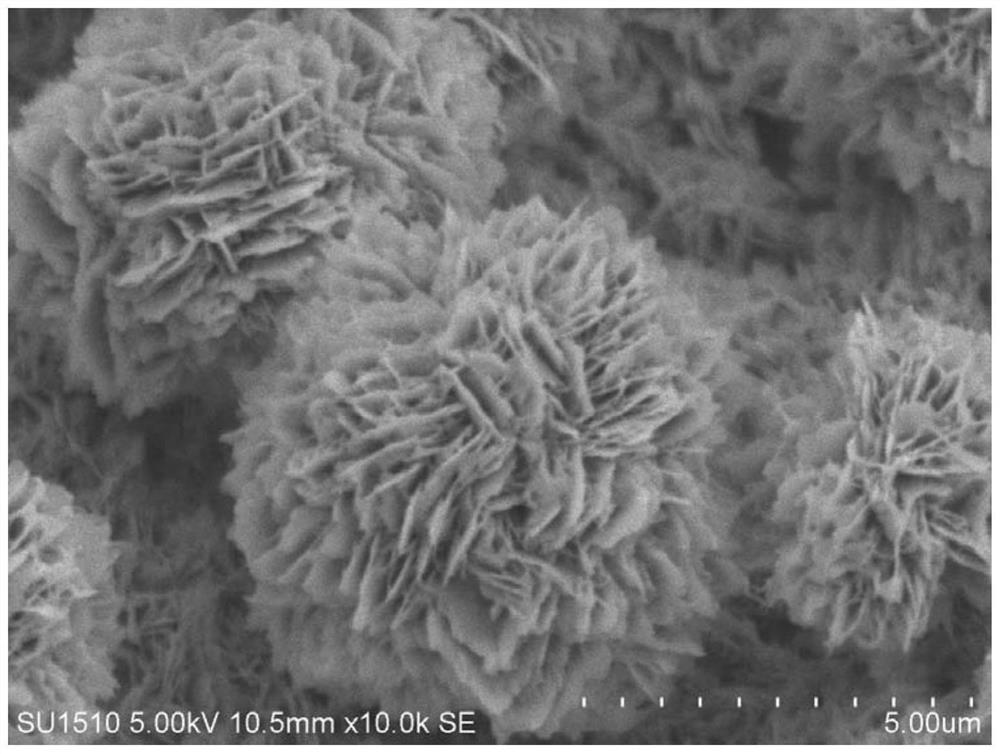

[0060] image 3 It is the morphology analysis of the copper oxide in Example 3 by a Hitachi su1510 scanning electron microscope. Depend on image 3 As shown, at this time, nanoflower-shaped copper oxide is formed, wherein the diameter of the nanoflower is about 1 μm˜5 μm.

[0061] A 5 μL water drop was dropped on the copper oxide surface prepared in Example 3 by a contact angle measuring instrument, and the static water contact angle was 0°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com