Preparation method of g-C3N4-based composite energetic material

A composite material, g-c3n4 technology, applied in the field of preparation of g-C3N4-based composite energetic materials, can solve problems such as energy loss of explosive samples, poor stability of ammonium nitrate explosives, low mechanical sensitivity, etc., and achieves good practical application prospects , Enhanced thermal stability and safety, the effect of strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] g-C 3 N 4 The preparation method of the matrix composite energetic material comprises the following steps:

[0042] S1. Put the crucible in a muffle furnace with urea as the raw material, and after calcination at a high temperature of 550°C, a light yellow powder g-C is obtained 3 N 4 ;

[0043] S2. The ammonium nitrate explosive (described with HMX as an example) and g-C 3 N 4 The materials are mixed according to a certain mass ratio, put into a mortar and grind evenly to obtain the HMX composite material 1 after physical grinding;

[0044] S3. Combining graphene oxide GO and g-C 3 N 4 The material was dispersed in deionized water, and GO and g-C were obtained after ultrasonic dispersion for 50 min 3 N 4 suspension;

[0045] S4. According to ammonium nitrate explosive: g-C 3 N 4 : Add appropriate amount of ammonium nitrate explosive to GO and g-C in different mass ratios of GO 3 N 4 In the suspension of HMX, g-C was obtained after ultrasonic dispersion fo...

Embodiment 1

[0052] g-C 3 N 4 The preparation method of HMX-based composite energetic material comprises the following process steps:

[0053] g-C 3 N 4 Powder preparation:

[0054] Grind 20 g of urea raw material evenly and place it in a crucible, raise the temperature of the raw material to 500°C at a heating rate of 2K / min, keep it warm for 4 hours and cool to room temperature, take it out, and grind it evenly to obtain g-C 3 N 4 Powder.

[0055] Follow HMX: g-C 3 N 4 The mass ratio is 97 / 3, the 30mg g-C 3 N 4 Add 970mg of HMX into the mortar and grind until the whole is uniform to get HMX / g-C 3 N 4 (97 / 3) composite material, the impact sensitivity is 5.0J (3.6J for raw material HMX), and the friction sensitivity is 128N (96N for raw material HMX).

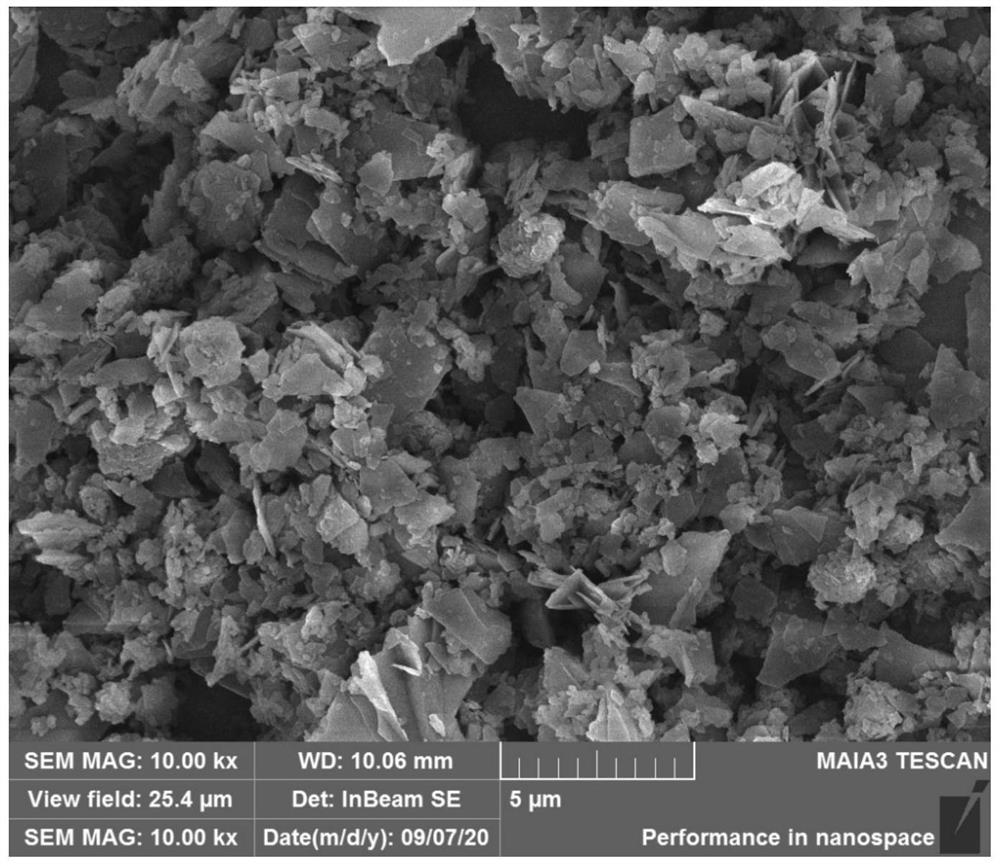

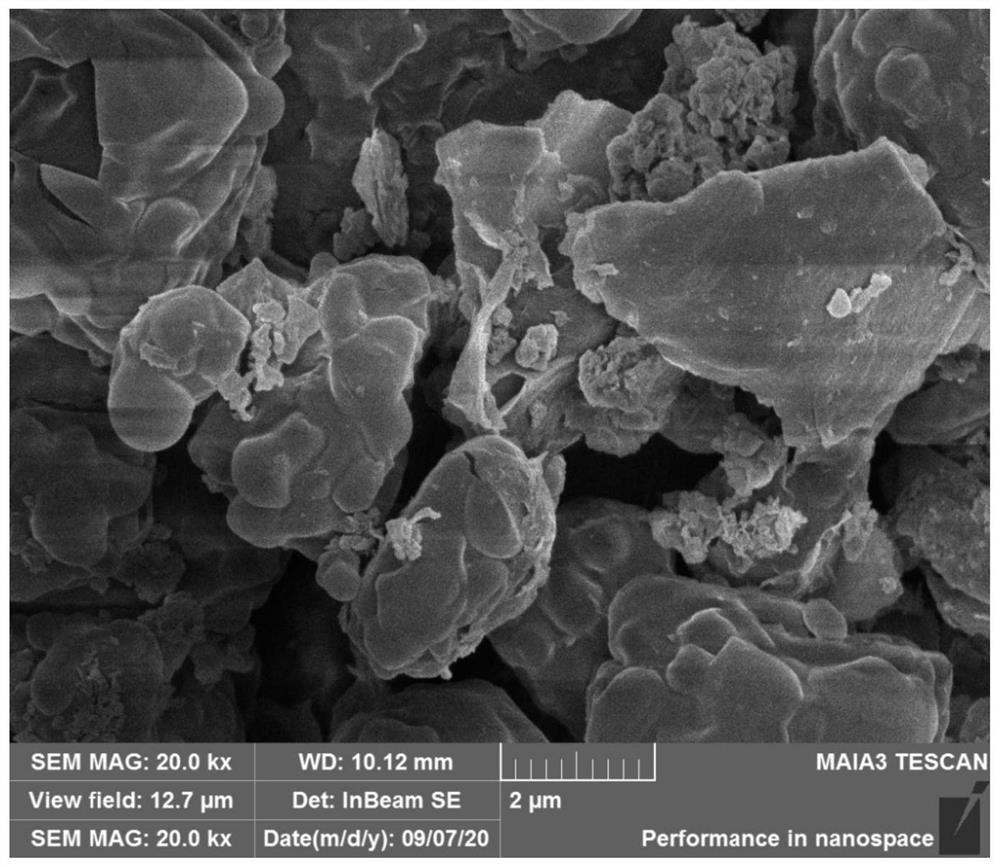

[0056] The g-C prepared in this embodiment 1 3 N 4 Powder and HMX / g-C 3 N 4 (97 / 3) composite material was analyzed by scanning electron microscope, and its crystal morphology is as follows figure 1 with figure 2 Shown, th...

Embodiment 2

[0058] g-C 3 N 4 and GO suspension preparation:

[0059] Weigh 20mg g-C respectively 3 N 4 Add 10mgGO and 60mL deionized water, and ultrasonically disperse for 50min to obtain g-C 3 N 4 and GO suspension (configuration concentration is 0.5mg / mL);

[0060] To HMX: g-C 3 N 4 : GO mass ratio is 97 / 2 / 1 for doping, adding 970mg of HMX explosives to the above g-C 3 N 4 and GO suspension, after ultrasonic treatment for 60min, the HMX, g-C 3 N 4 Add 64 μL of hydrazine hydrate (80% mass fraction) to the mixture with GO suspension, stir in an oil bath at 100°C at a speed of 400r / min for 2h, cool to room temperature, filter with suction, and rinse with deionized water at room temperature for several times , placed in a vacuum drying oven to obtain g-C 3 N 4 HMX / g-C with GO as desensitizer 3 N 4 / rGO (97 / 1 / 2) composite material, its impact sensitivity is 12J (3.6J for raw material HMX), and its friction sensitivity is 128N (96N for raw material HMX).

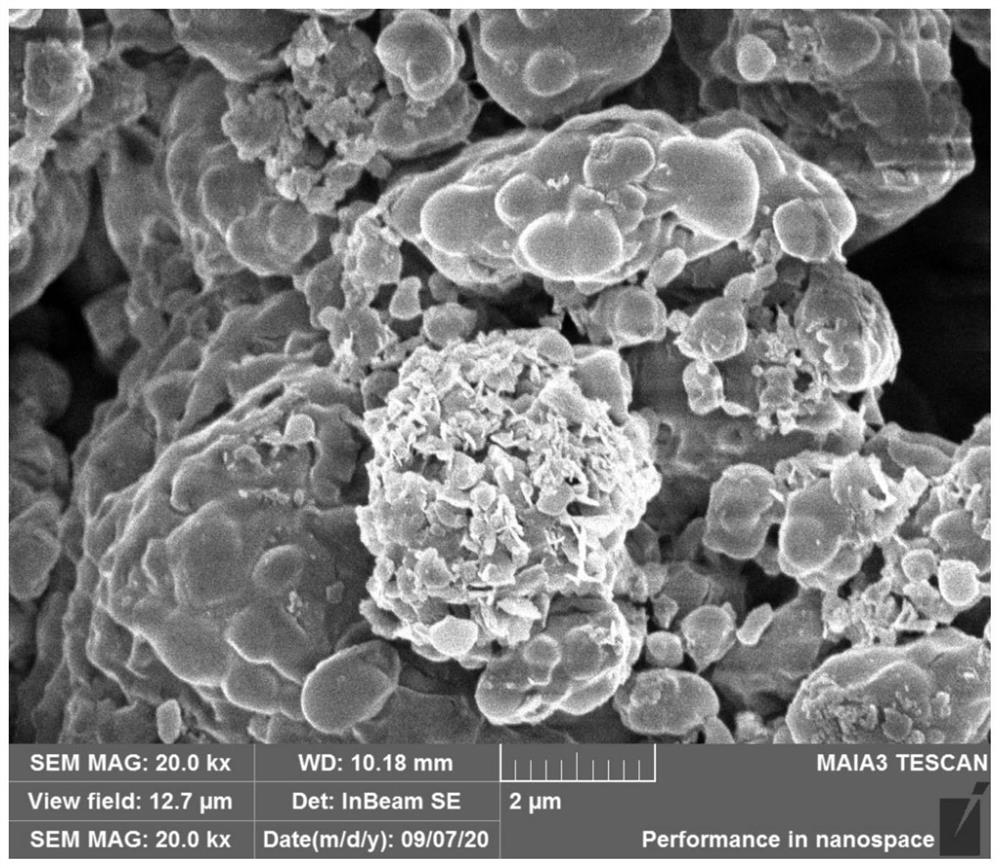

[0061] The HMX / g-C p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com