Xylene gas sensor based on SnS2 sensitive layer modified by gold-palladium alloy and preparation method of xylene gas sensor

A technology of gas sensor and gold-palladium alloy, which is applied in the field of xylene gas sensor and its preparation, can solve problems such as xylene pollution, and achieve the effects of improved gas sensing performance, low cost, and low working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

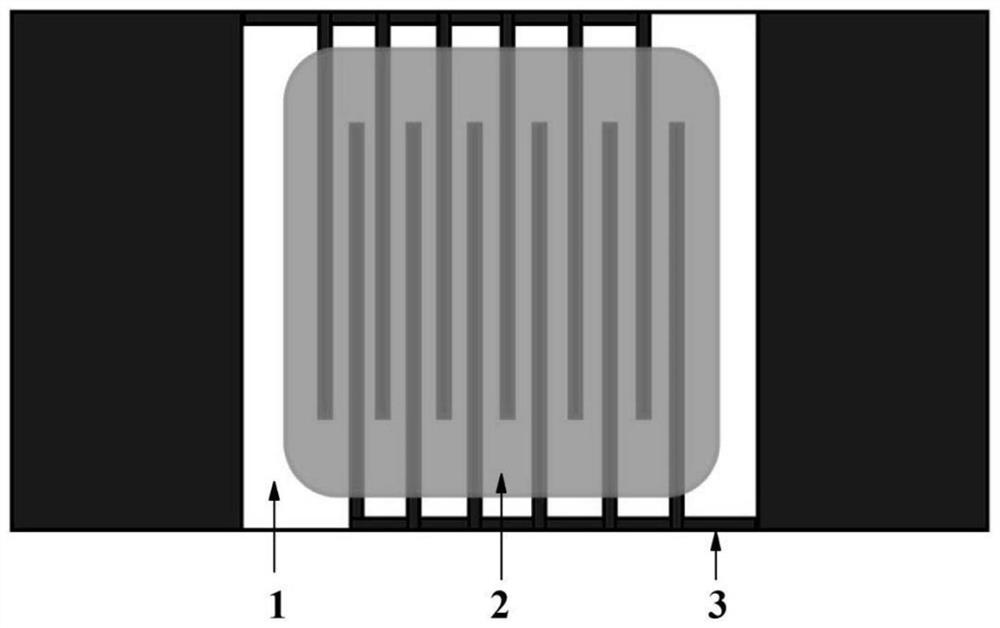

[0032] 1. Treatment of Pd metal interdigitated electrodes:

[0033] First, use acetone and ethanol cotton balls to wipe the Al with Pd metal interdigitated electrodes with a width of 3mm and a length of 4mm prepared by screen printing technology. 2 o 3 The substrate is clean, and then the Al with Pd metal interdigitated electrodes 2 o 3 The substrate was placed in acetone, ethanol and deionized water in turn, ultrasonically cleaned for 5 minutes respectively, and finally dried at 100°C for later use.

[0034] Among them, the present invention uses screen printing technology to prepare Pd metal interdigitated electrodes. The specific method is as follows: mix the ink [Jiahua JX07500487]: Pd powder: diluent in a mass ratio of 1:1:2, and stir to make a paste; then inject the paste into the On the screen plate, the paste was scraped under the conditions of an inclination angle of 30° and a pressure of 5 Newtons, the electrodes were printed and dried, and the preparation of Pd ...

Embodiment 1

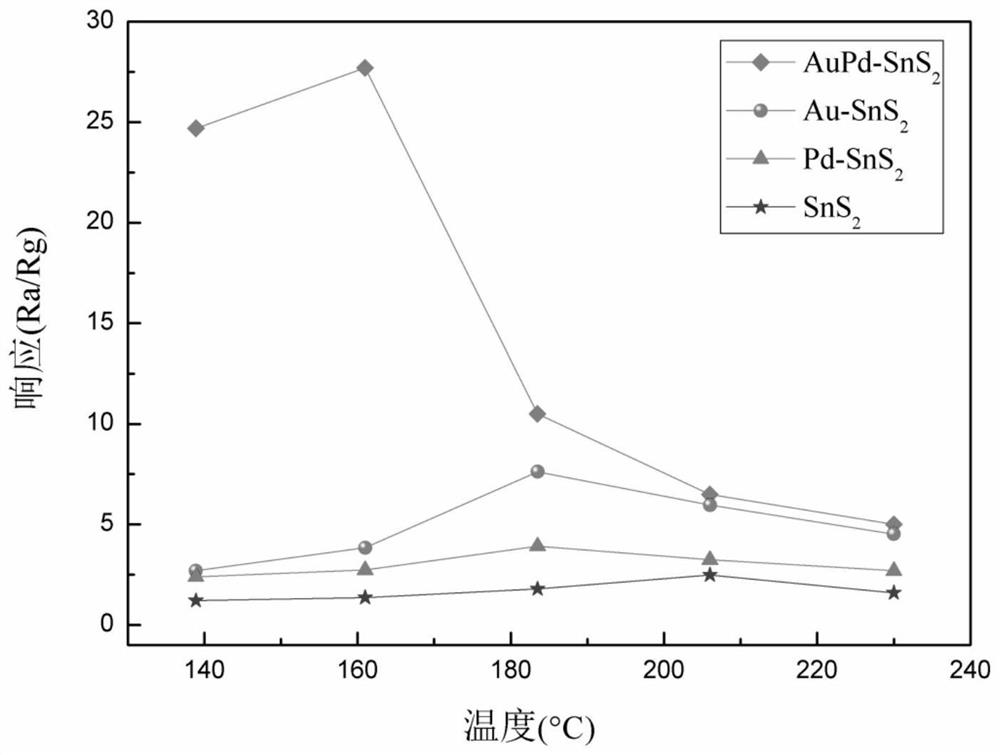

[0045] The sensitivity is 2.49 (100ppm xylene);

[0046] The response time is 6 seconds and the recovery time is 8 seconds.

Embodiment 2

[0048] The sensitivity is 7.62 (100ppm xylene);

[0049] The response time is 5 seconds and the recovery time is 7 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com