Malic acid-chitosan nanopore hydrogel microspheres as well as preparation method and application thereof

A technology of chitosan nano and hydrogel microspheres, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation method of malic acid-chitosan nanoporous hydrogel microspheres

[0037] (1) Mix malic acid and chitosan (deacetylation degree 90%) according to the mass ratio of 1:3, add the mixture to pure water to prepare a dispersion with a mass fraction of 1.5%, stir vigorously at room temperature for 4 hours, and form a uniform malic acid-chitosan hydrosol.

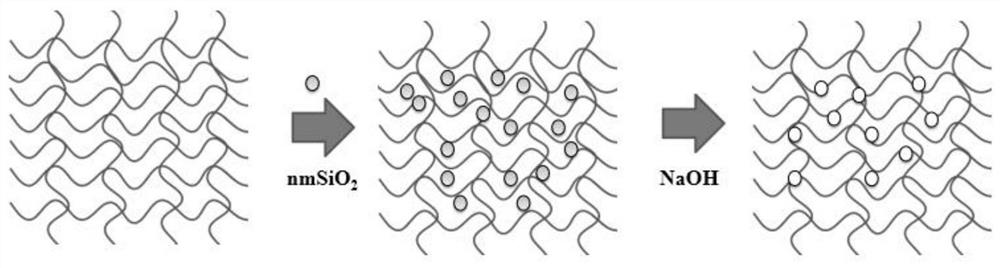

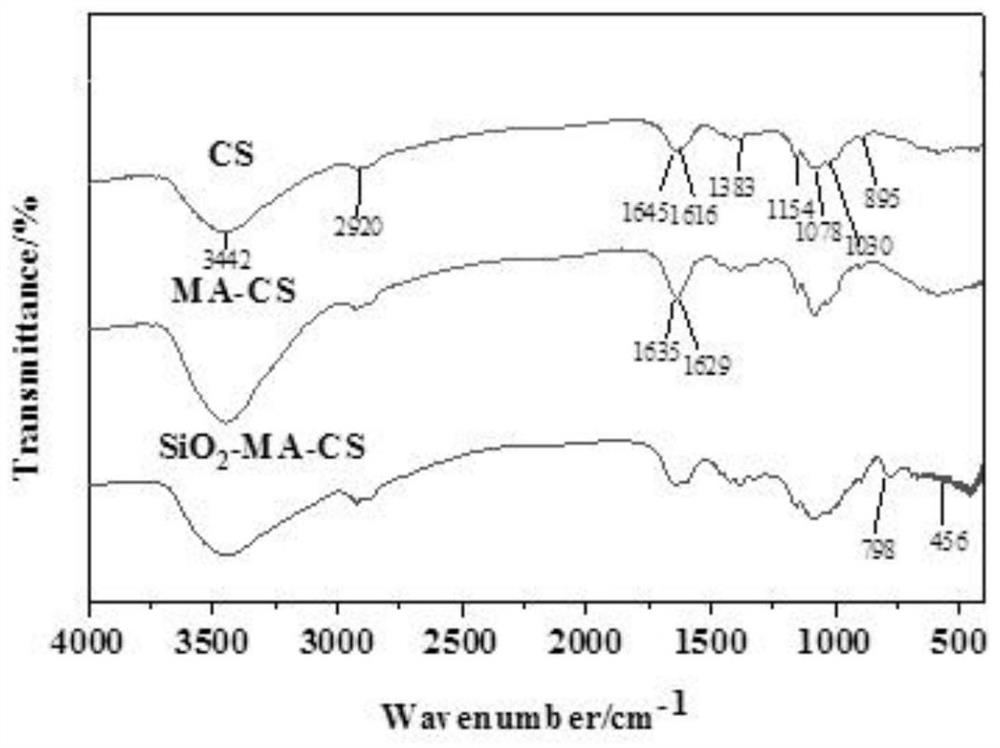

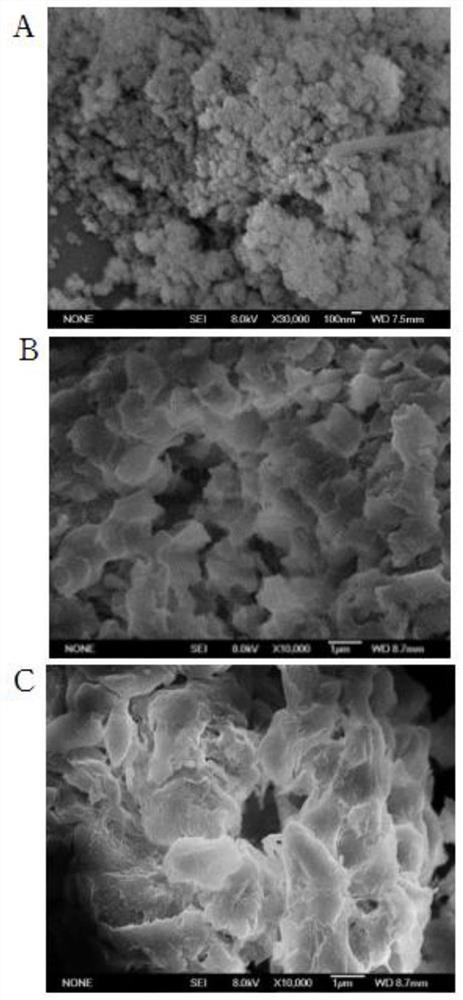

[0038] (2) adding mass fraction to the hydrosol described in step (1) is 0.4% nano-silica and 1.0% glycerin, stirred at room temperature for 2 h, ultrasonically treated for 2 h, and the homogeneous sol obtained was added dropwise to The mass fraction is 10% NaOH solution, kept at 80°C for 2h to dissolve the silica particles and generate a porous structure. Finally, wash with distilled water to remove the remaining NaOH, freeze-dry and grind through a 100-mesh sieve, collect and store in a desiccator, such as figure 1 Shown is a schematic diagram of the synthesis of malic acid-chitosan nanoporous hydrog...

Embodiment 2

[0039] Example 2 Preparation method of malic acid-chitosan nanoporous hydrogel microspheres

[0040] (1) Mix malic acid and chitosan (90% degree of deacetylation) according to the mass ratio of 1:4, add the mixture to pure water to prepare a dispersion with a mass fraction of 0.5%, stir vigorously at room temperature for 4 hours, and form a uniform malic acid-chitosan hydrosol.

[0041] (2) Adding mass fraction of 0.2% nano silicon dioxide and 0.5% glycerin to the aqueous sol in step (1), stirring at room temperature for 2 h, ultrasonic treatment for 1 h, and adding the obtained homogeneous sol dropwise to The mass fraction is 8% NaOH solution, kept at 60°C for 2h to dissolve the silica particles and generate a porous structure. Finally, wash with distilled water to remove the remaining NaOH, freeze-dry, grind through a 100-mesh sieve, collect and store in a desiccator.

Embodiment 3

[0042] Example 3 Preparation method of malic acid-chitosan nanoporous hydrogel microspheres

[0043] (1) Mix malic acid and chitosan (90% degree of deacetylation) according to the mass ratio of 1:5, add the mixture to pure water to prepare a dispersion with a mass fraction of 1.5%, stir vigorously at room temperature for 4 hours, and form a uniform malic acid-chitosan hydrosol.

[0044](2) Adding mass fraction of 0.6% nano-silica and 1.0% glycerin to the hydrosol in step (1), stirring at room temperature for 3 h, ultrasonic treatment for 2 h, and adding the obtained homogeneous sol dropwise to The mass fraction is 10% NaOH solution, kept at 80°C for 1 h to dissolve the silica particles and generate a porous structure. Finally, wash with distilled water to remove the remaining NaOH, freeze-dry, grind through a 100-mesh sieve, collect and store in a desiccator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com