Viscoelastic fluid soft abrasive material for abrasive particle flow finishing processing of surface of difficult-to-process material

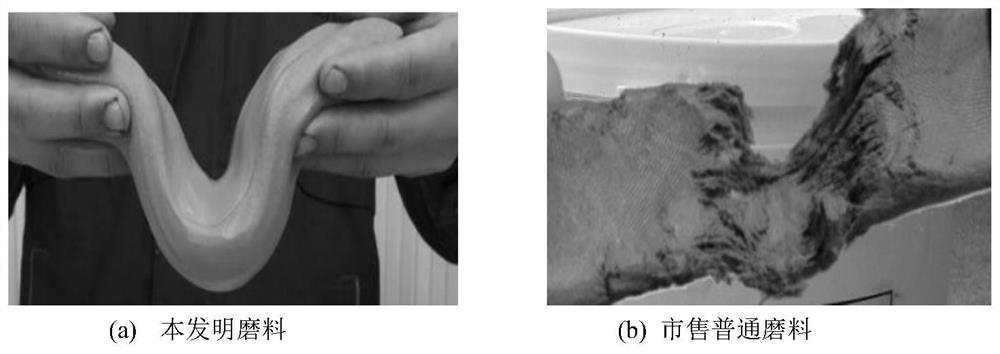

A viscoelastic and soft abrasive technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problem that the quality of finishing processing cannot meet the technical indicators, the fusion of abrasive grains and carrier medium is not good, and the abrasive grains are easy to stick to the workpiece and other problems, to achieve the effect of wide temperature range, good viscoelasticity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

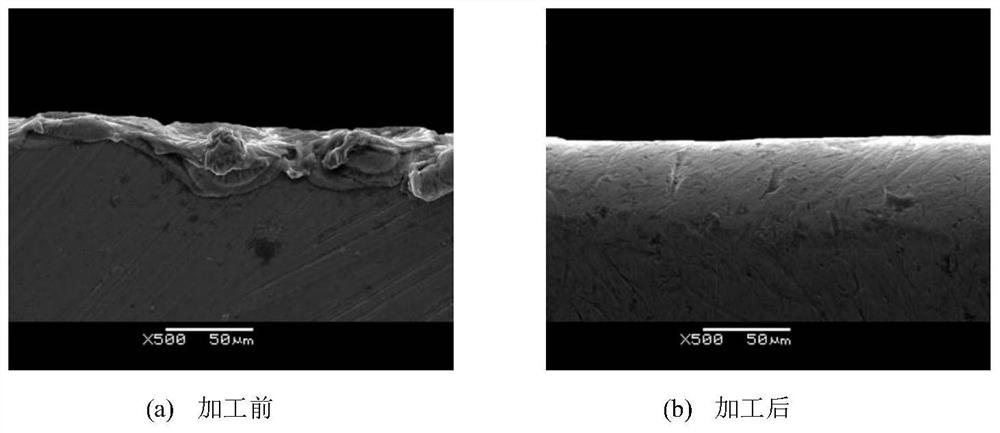

[0021] Such as Figure 1-2 shown.

[0022] First, 20 kg of SiC abrasive grains with an average particle diameter of 30 mesh, 10 kg of SiC abrasive grains with an average particle diameter of 60 mesh, and 10 kg of SiC abrasive grains with an average particle diameter of 500 mesh were selected from the market. Next, use long carbon chain C8-C14 modified silane to carry out lipophilic treatment on its surface, mix well and add 25kg of carrier medium methyl vinyl silicone rubber. Then, add 10kg of alkyl silicone oil (which can effectively increase the wear resistance and temperature resistance of the abrasive), 15kg of white oil (softener, used to adjust the viscoelasticity and hardness of the abrasive), and 5kg of dimethyl Base silicone oil (lubricant, increase the lubrication performance of the abrasive), 2kg of paraffin wax (lubricant, increase the lubrication performance of the abrasive), 3kg of sodium stearate (heat stabilizer, increase the thermal stability of the abrasive)...

Embodiment 2

[0025] First of all, 30 kg of diamond abrasive grains with an average particle diameter of 20 mesh, 15 kg of diamond abrasive grains with an average particle diameter of 50 mesh and 15 kg of diamond abrasive grains with an average particle diameter of 300 mesh were selected. Next, use long carbon chain C8-C14 modified silane to do lipophilic treatment on the surface, mix well and add 20kg of carrier medium methyl vinyl silicone rubber. Then, add 5kg of alkyl silicone oil (which can effectively increase the wear resistance and temperature resistance of the abrasive), 10kg of white oil (softener, used to adjust the viscoelasticity and hardness of the abrasive), 2kg of dimethyl Base silicone oil (lubricant, increase the lubrication performance of the abrasive), 2kg of paraffin wax (lubricant, increase the lubrication performance of the abrasive), 1kg of sodium stearate (heat stabilizer, increase the thermal stability of the abrasive). Finally, it can be configured into 100kg visc...

Embodiment 3

[0027] First, choose 22 kg of cubic boron nitride (CBN) with an average particle diameter of 25 mesh, 11.5 kg of cubic boron nitride (CBN) with an average particle diameter of 55 mesh and 11.5 kg of cubic boron nitride (CBN) with an average particle diameter of 400 mesh. kg. Next, use long carbon chain C8-C14 modified silane to carry out lipophilic treatment on its surface, mix well and add 22kg of carrier medium methyl vinyl silicone rubber. Then, add 8kg of alkyl silicone oil (which can effectively increase the wear resistance and temperature resistance of the abrasive), 13kg of white oil (softener, used to adjust the viscoelasticity and hardness of the abrasive), and 3kg of dimethyl Base silicone oil (lubricant, increase the lubrication performance of abrasives), 7kg of paraffin wax (lubricant, increase the lubrication performance of abrasives), 2kg of sodium stearate (heat stabilizer, increase the thermal stability of abrasives). Finally, it can be configured into 100kg v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com