Method and device for cooperatively treating organic fluorine and terpene raffinate through plasma cracking

A plasma cracking and co-processing technology, applied in the field of chemical waste treatment, can solve the problems of not creating economic value, easily producing dioxins, incomplete incineration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

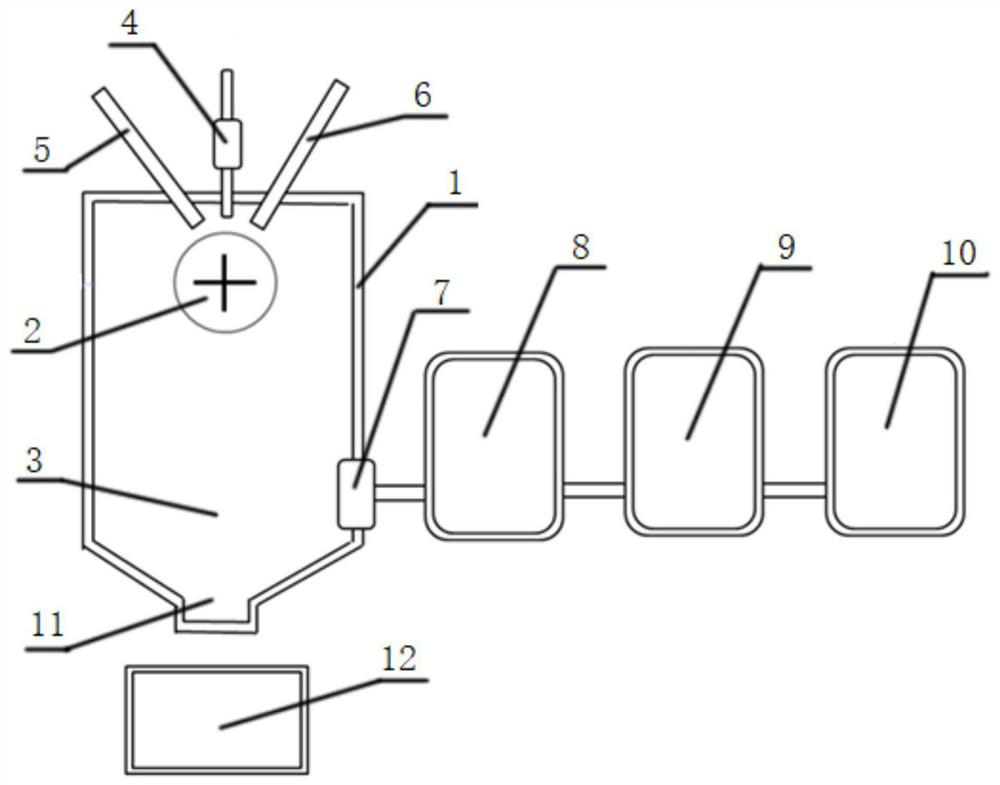

[0028] see figure 1 As shown, it is a method of plasma cleavage that is provided in this embodiment to treat organic fluorine and terpene residual, the apparatus including a cracking furnace 1, a cleavage furnace 1 having a vertical cylindrical shape of a furnace body, including disposed in the furnace body The high temperature zone 2 in the upper section of the furnace is provided at a low temperature zone 3 in the lower portion of the high temperature zone; the plasma spray gun 4 is disposed vertically at the center of the upper surface of the furnace body, and the port of the plasma gun 4 is disposed in the high temperature zone 2 in the furnace body. Plasma is a method of generating high temperatures using a plasma torch or plasma beam generated by the electrode, producing a plasma torch or plasma beam can be exchanged, DC, power frequency, and high frequency, etc., the arc temperature is very high and can instantly realize high temperatures. Turn on the power supply, the curr...

Embodiment 2

[0038] Treatment of tetrafluoroethylene residuals and terpene residues, as follows:

[0039] Synergistic processing is carried out in a cracking furnace, and the lysis of furnace furnace negative pressure is controlled in -300Pa;

[0040] Turn on the power supply, current in the port of the plasma spray gun, form a high temperature arc region, when the plasma arc is warmed to 2000 ° C, and Tourifluoroethylene residual liquid, tetrafluoroethylene residue, tetrafluoroethylene residue The entry mass ratio of the ethylene residue is 30 kg / h: 13 kg / h. The tetrafluoroethylene residual group is: 80% -95% octoparbutane, whole fluoroisine isobutylene 5% -10%, tetrafluoroethylene or 5% of the polymer thereof, and a small amount of chlorofluoromethane, etc.; The main ingredient of the ethylenofin is C 10 Hide 16 And the analog is about 80%, and the other is a recombination and a small amount of water, and recombinantly divided into fluorine-containing compounds.

[0041] In an aerobic en...

Embodiment 3

[0046] Treatment of hexafluoropropene residual and terpene residual liquid, as follows:

[0047] Cooperative treatment is carried out in a cracking furnace, and the pulley of the cracking furnace is controlled in -900Pa;

[0048] Turn on the power supply, current in the port of the plasma spray gun, form a high temperature arc region, when the plasma arc is warmed to 2000 ° C, and the hexafluoropropene residual liquid and terpene residue, hexafluoropropylene residual liquid, terpenoids The entry mass ratio of the ethylenofin is 40 kg / h: 17kg / h. Among them, the hexafluoropropylene residual liquid is: about 90% of all fluoroisine, about 10% of octopulfurine, and a small amount of hexafluoropropylene or the like. The main component of terpene residue is C 10 Hide 16 And the analog is about 80%, and the other is a recombination and a small amount of water, and recombinantly divided into fluorine-containing compounds.

[0049] In an aerobic environment, the hexafluoropropylene resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com