Combined inhibitor and micro-fine particle copper-zinc bulk concentrate flotation separation method

A technology combining inhibitors and separation methods, applied in flotation, solid separation, etc., can solve the problems of inconvenient operation and management, difficult treatment of flotation wastewater, high metal interholding rate, etc., and achieve easy processing and recycling, copper and zinc Good separation effect and low intermetallic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

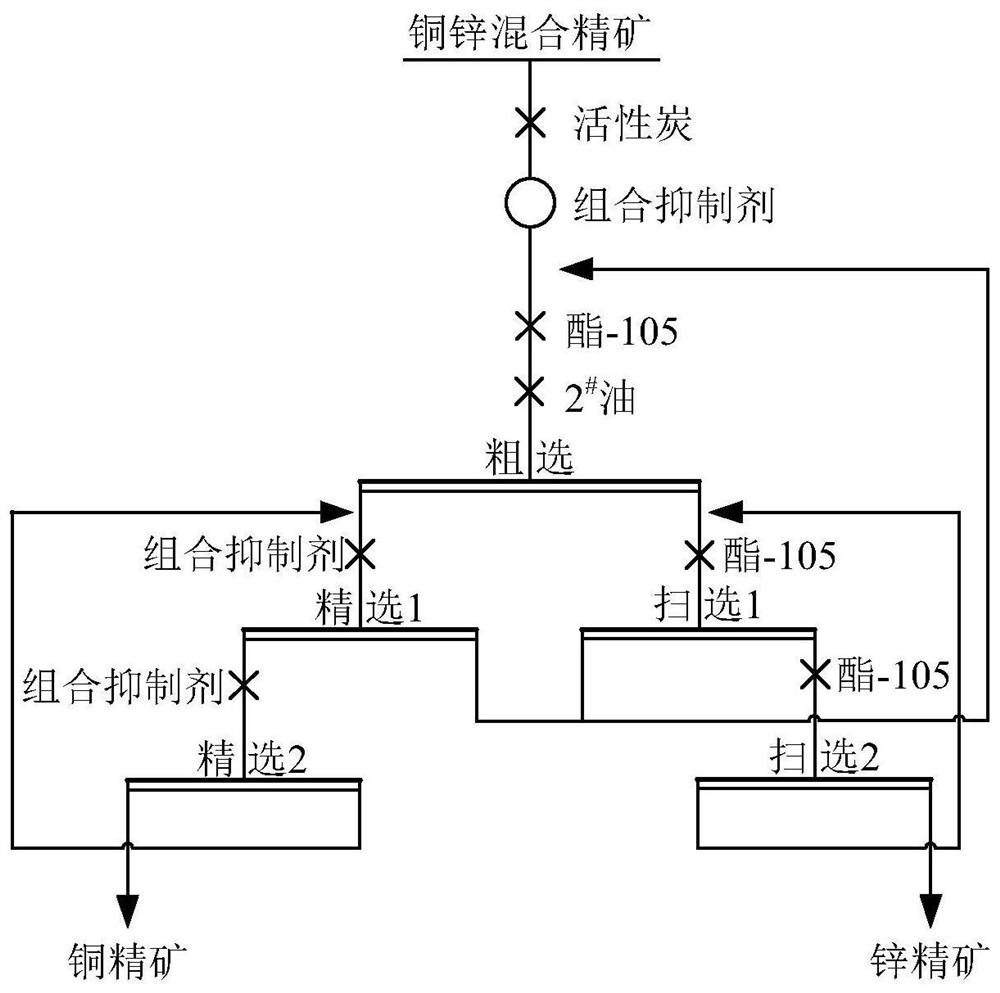

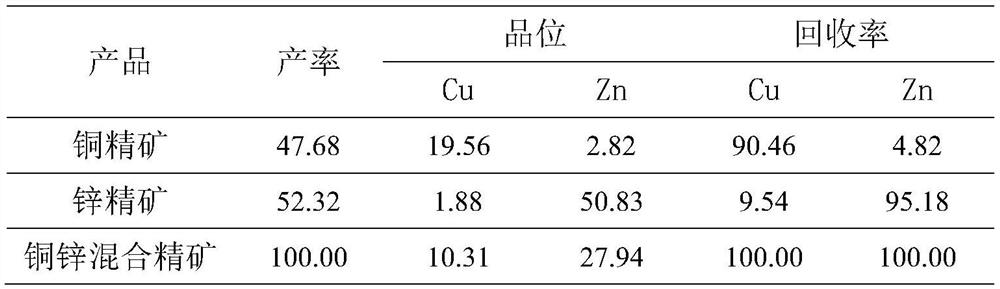

[0026] A copper-zinc mixed concentrate contains 10.31% copper and 27.94% zinc. The results of technological mineralogy show that the main metal minerals in this copper-zinc mixed concentrate are chalcopyrite, chalcocite, sphalerite and pyrite. Cu and Zn metals are 74.70% and 75.94% respectively at -0.038mm particle size. Adopt a kind of combined inhibitor provided by the present invention and the flotation separation method of fine-grained copper-zinc mixed concentrate, carry out laboratory small-scale closed-circuit test to this ore sample, the concrete steps of test are as follows:

[0027] First, add activated carbon to the copper-zinc mixed concentrate to remove the drug by stirring, and then grind the ore. At the same time, add citric acid and sodium pyrosulfite during the grinding process. The dosage of activated carbon, citric acid and sodium pyrosulfite is 60g / t and 80g / t respectively. t, 900g / t, to obtain the overflow product of grinding;

[0028] Add ester-105 0.8g / ...

Embodiment 2

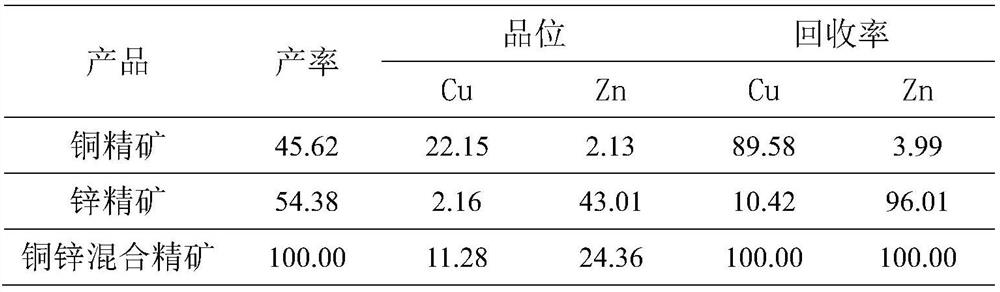

[0036] A copper-zinc mixed concentrate contains 11.28% copper and 24.36% zinc. The results of technological mineralogy show that the main metal minerals in this copper-zinc mixed concentrate are chalcopyrite, sphalerite and pyrite. Cu and Zn metals are 76.55% and 78.96% respectively at -0.038mm particle size. Adopt a kind of combined inhibitor provided by the present invention and the flotation separation method of fine-grained copper-zinc mixed concentrate, carry out laboratory small-scale closed-circuit test to this ore sample, the concrete steps of test are as follows:

[0037] (1) Add activated carbon to the copper-zinc mixed concentrate to remove the drug by stirring, and then grind the ore. At the same time, add citric acid and sodium thiosulfate during the grinding process. The dosages of activated carbon, citric acid and sodium thiosulfate are respectively 64g / t, 150g / t, 1600g / t to obtain the overflow product of grinding;

[0038] (2) Add ester-105 0.6g / t, 2 # Oil 24...

Embodiment 3

[0046] A copper-zinc mixed concentrate contains 9.89% copper and 15.64% zinc. The results of technological mineralogy show that the main metal minerals in this copper-zinc mixed concentrate are chalcopyrite, sphalerite, pyrite and a small amount of sphalerite . Cu and Zn metals are 72.21% and 76.33% respectively at -0.038mm particle size. Adopt a kind of combined inhibitor provided by the present invention and the flotation separation method of fine-grained copper-zinc mixed concentrate, carry out laboratory small-scale closed-circuit test to this ore sample, the concrete steps of test are as follows:

[0047](1) Add activated carbon to the copper-zinc mixed concentrate to remove the drug by stirring, and then grind the ore. At the same time, add citric acid, sodium thiosulfate and sodium pyrosulfite, activated carbon, citric acid, and sodium thiosulfate during the grinding process and sodium pyrosulfite are used in amounts of 65g / t, 100g / t, 1100g / t, and 1200g / t, respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com