Ultrahigh-strength tough cement paste system for well cementation as well as preparation and application thereof

An ultra-high-strength, cement slurry technology, applied in the field of deep shale gas and high-temperature deep-well cementing slurry, can solve the problems of difficulty in applying high-temperature deep-well cementing, reducing the elastic modulus of cement stone, and poor temperature resistance of rubber particles. To achieve the effect of adjustable thickening time, avoiding strength decline and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

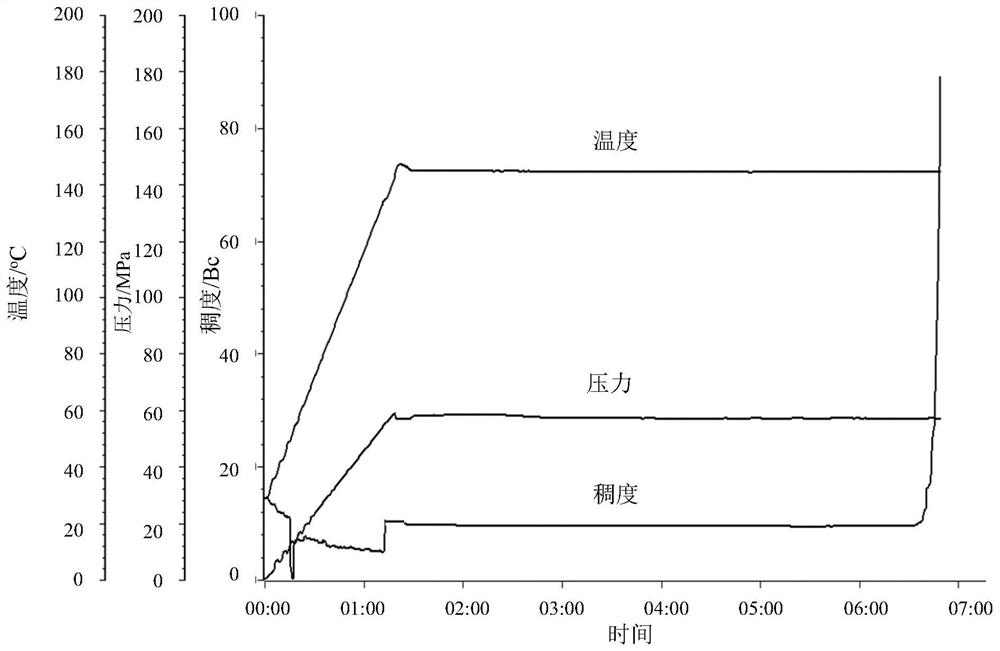

Embodiment 1

[0052] This embodiment provides an ultra-high-strength ductile cement slurry system for well cementing, wherein the raw material composition of the ultra-high-strength ductile cement slurry system for well cementing includes:

[0053] 100 parts by weight of G-grade oil well cement, 20 parts by weight of high-temperature reinforcing materials, 0.5 parts by weight of inorganic toughening materials, 0.5 parts by weight of suspension stabilizers, 2 parts by weight of micro silicon, 0.5 parts by weight of dispersants, 3 parts by weight The fluid loss reducing agent of 1.5 parts by weight, the retarder of 1.5 parts by weight, the defoamer of 0.3 parts by weight, the clear water of 47 parts by weight.

[0054] In this embodiment, the high-temperature reinforcing material is a combination of ultrafine silica fume and ultrafine cement, and the mass ratio of the two is 1:1, wherein the particle size of the ultrafine cement is not greater than 5 microns, and the superfine silica fume The...

Embodiment 2

[0067] This embodiment provides an ultra-high-strength ductile cement slurry system for well cementing, wherein the raw material composition of the ultra-high-strength ductile cement slurry system for well cementing includes:

[0068] 100 parts by weight of G-grade oil well cement, 35 parts by weight of high-temperature reinforcing materials, 1 part by weight of inorganic toughening materials, 1 part by weight of suspension stabilizers, 3 parts by weight of micro silicon, 0.8 parts by weight of dispersants, 3.5 parts by weight The water loss reducing agent of 3 parts by weight, the retarder of 3 parts by weight, the defoamer of 0.3 parts by weight, the clear water of 48.5 parts by weight.

[0069] In this embodiment, the high-temperature reinforcing material is quartz sand with a particle size not greater than 20 microns and a purity not lower than 96%.

[0070] The inorganic toughening material is a combination of brucite fibers and calcium carbonate whiskers, and the mass ra...

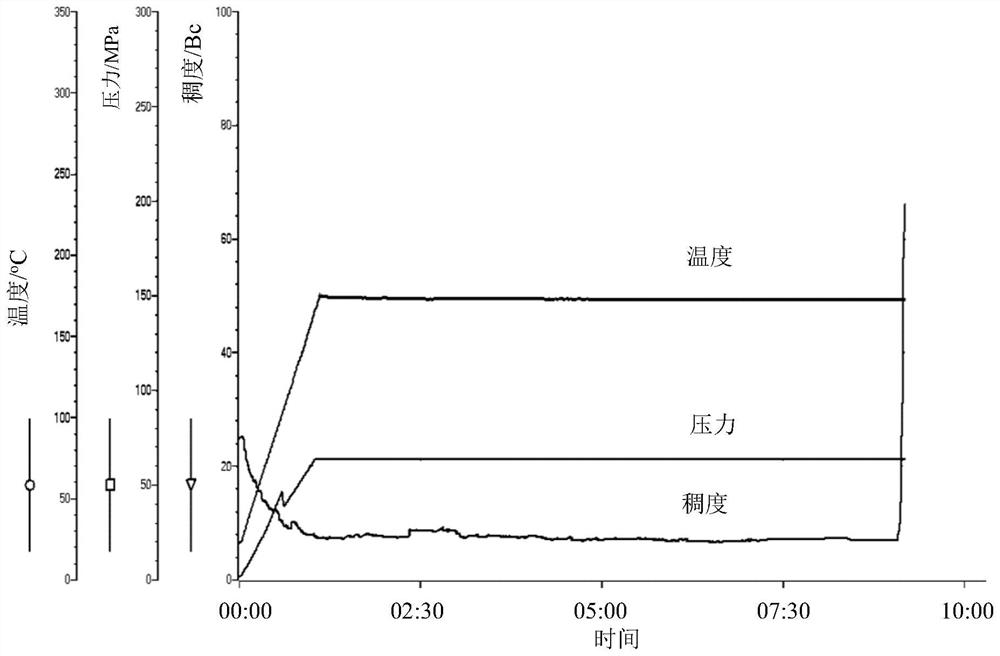

Embodiment 3

[0082] This embodiment provides an ultra-high-strength ductile cement slurry system for well cementing, wherein the raw material composition of the ultra-high-strength ductile cement slurry system for well cementing includes:

[0083] 100 parts by weight of G-grade oil well cement, 40 parts by weight of high-temperature reinforcing materials, 2 parts by weight of inorganic toughening materials, 1.5 parts by weight of suspension stabilizers, 4 parts by weight of micro silicon, 1.0 parts by weight of dispersants, 4.5 parts by weight The water loss reducing agent of 5 parts by weight, the retarder of 5 parts by weight, the defoamer of 0.3 parts by weight, the clear water of 52 parts by weight.

[0084] In this embodiment, the high-temperature reinforcing material is a combination of ultrafine silicon powder and metakaolin, the mass ratio of the two is 4:1, wherein the particle size of the ultrafine silicon powder is not greater than 10 microns, and the purity is not low At 96%, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com