A kind of antimony gold complex resource collaborative smelting method

A smelting method and complex technology, applied in the direction of improving process efficiency, etc., can solve the problems of precious metal loss, precious metal gold and silver loss, low antimony recovery rate, etc., and achieve the effect of efficient recovery and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

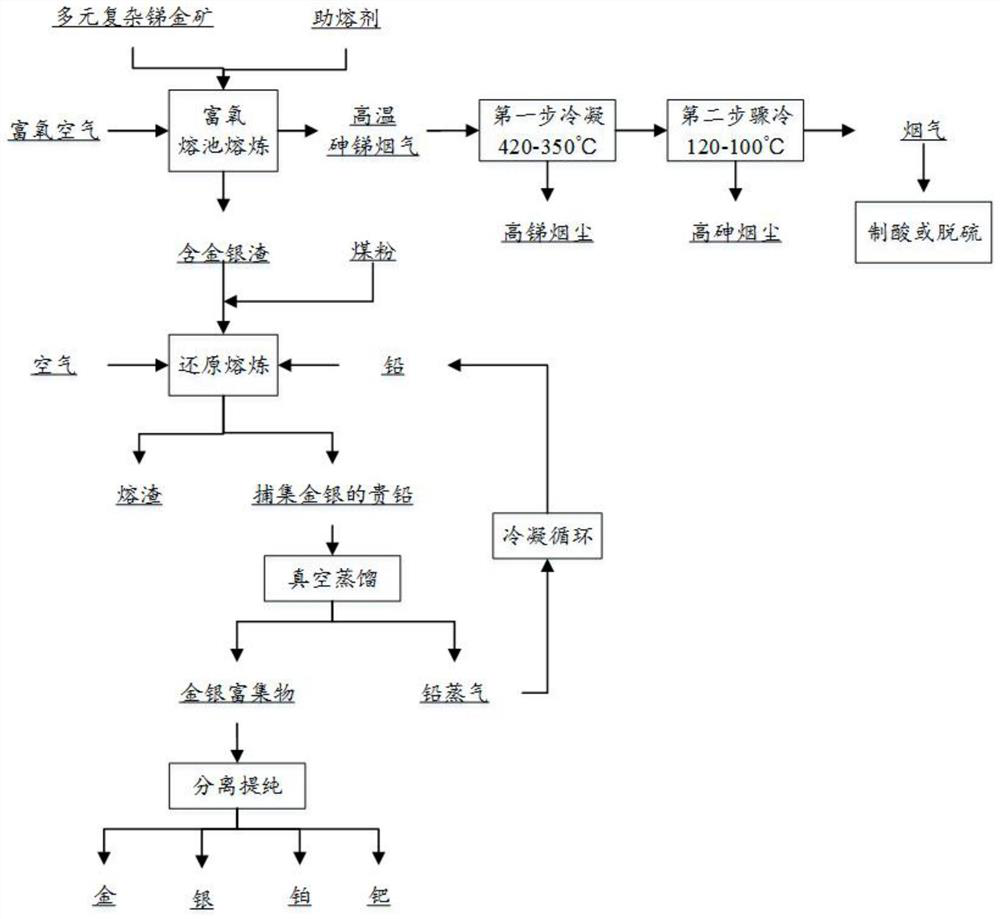

[0036] like figure 1 As shown, a method for synergistic smelting of complex resources of antimony and gold includes the following steps:

[0037] (1) Grind antimony-containing gold ore and stibnite (grind to 200 mesh) and dry in a vacuum drying oven at 60°C for 60 min to obtain pre-treated ore. Antimony 23.4% (mass content), gold 20.07g / t, silver 50.49g / t;

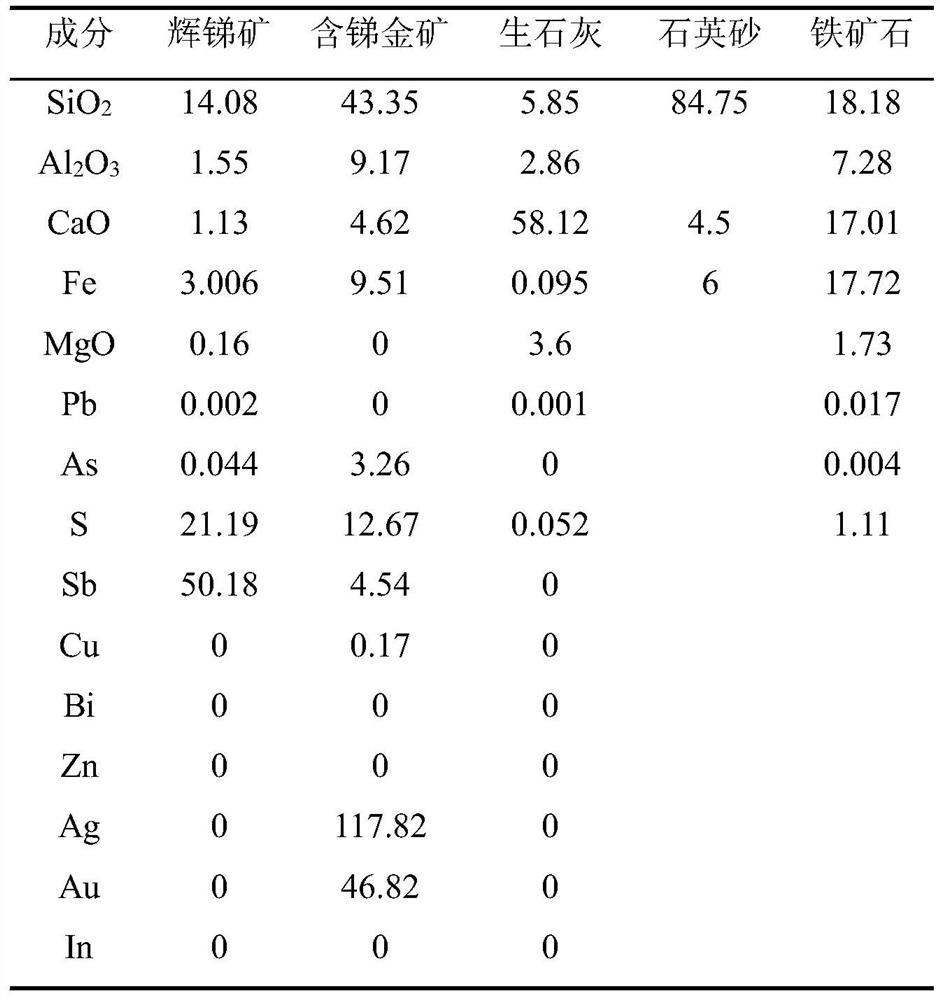

[0038] (2) 600g of pretreated ore material, 30g of quicklime, 80g of iron ore, and 20g of quartz sand are sent into a lift-type crucible resistance furnace for oxygen-enriched molten pool smelting. The smelting raw material composition table is shown in Table 1. By adjusting the experimental parameters, the oxygen concentration in the oxygen-enriched gas is 50% and the oxygen flow rate is 150m 3 / s, the smelting temperature of the molten pool is 1100 °C, and the smelting time of the molten pool is 50 minutes to obtain high-temperature arsenic-antimony flue gas and precious metal slag;

[0039] (3) Control the condensati...

Embodiment 2

[0046] like figure 1 As shown, a method for synergistic smelting of complex resources of antimony and gold includes the following steps:

[0047] (1) Grind antimony-containing gold ore and brittle sulphur-lead-antimony ore (grind to 200 mesh) and then dry it in a vacuum drying oven at 60°C for 60 minutes to obtain pretreated ore. The treated ore contains 8.92% antimony, 19.24g / t gold and 373.4g / t silver;

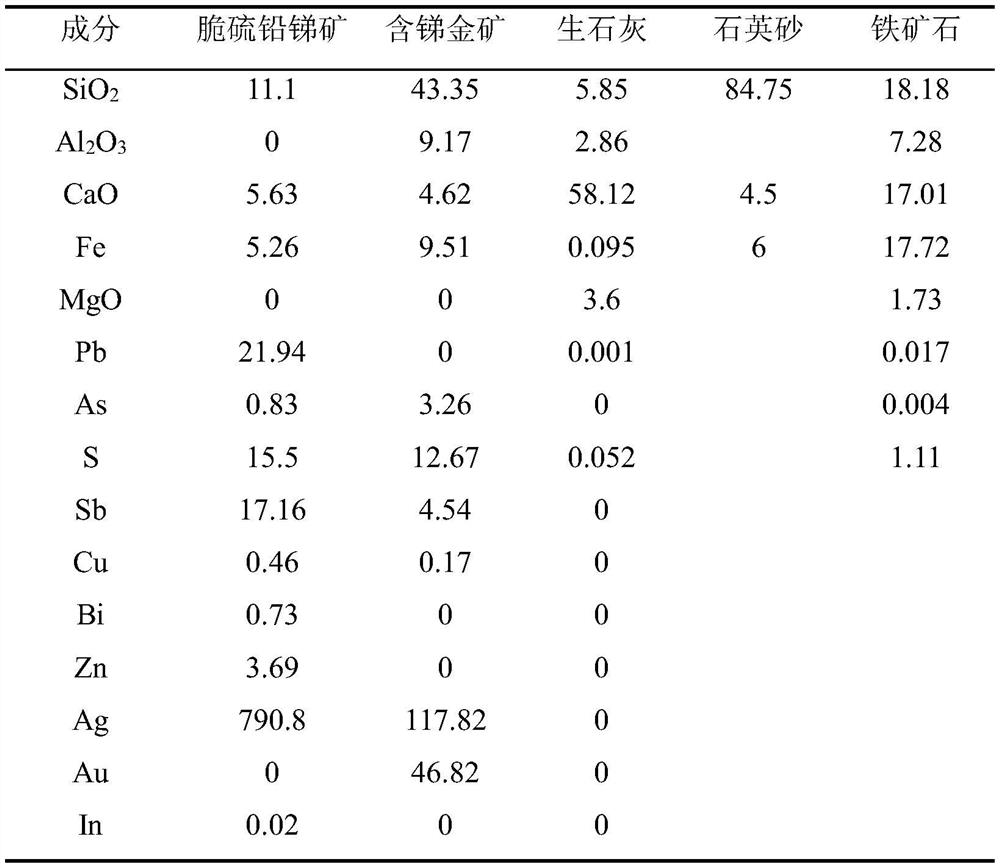

[0048] (2) 900g of pretreated mineral material, 45g of quicklime, 120g of iron ore, and 30g of quartz sand will be sent into a lift-type crucible resistance furnace for oxygen-enriched molten pool smelting, and the smelting raw material composition table is shown in Table 2. By adjusting the experimental parameters, the oxygen concentration in the oxygen-enriched gas is 55%, and the oxygen flow rate is 200 m 3 / s, the melting temperature of the molten pool is 1200 °C, and the melting time of the molten pool is 50 minutes, to obtain high-temperature arsenic-antimony flue ga...

Embodiment 3

[0056] like figure 1 As shown, a method for synergistic smelting of complex resources of antimony and gold includes the following steps:

[0057] (1) Grind antimony-containing gold ore (grind to 200 mesh) and then dry it in a vacuum drying oven at 60°C for 60 minutes to obtain pretreated ore. The pretreated ore contains 3.82% antimony, 39.42g / t gold, and 99.21g / t silver. ;

[0058] (2) 800g of pretreated mineral material, 50g of quicklime, 70g of iron ore, and 30g of quartz sand will be sent into a lift-type crucible resistance furnace for oxygen-enriched molten pool smelting, and the smelting raw material composition table is shown in Table 3. By adjusting the experimental parameters, the oxygen concentration in the oxygen-enriched gas is 60%, and the oxygen flow rate is 250 m 3 / s, the melting temperature of the molten pool is 1250 °C, and the melting time of the molten pool is 50 minutes, to obtain high-temperature arsenic-antimony flue gas and precious metal slag;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com