Hydroxyl functionalized carbon dot modified bismuth vanadate film, and preparation method and application thereof

A functionalized bismuth vanadate technology, applied in energy input, electrodes, electrolysis process, etc., can solve the problems of poor bulk phase transport and surface transport capacity, achieve efficient and simple methods, and promote bulk phase transport and surface transport The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

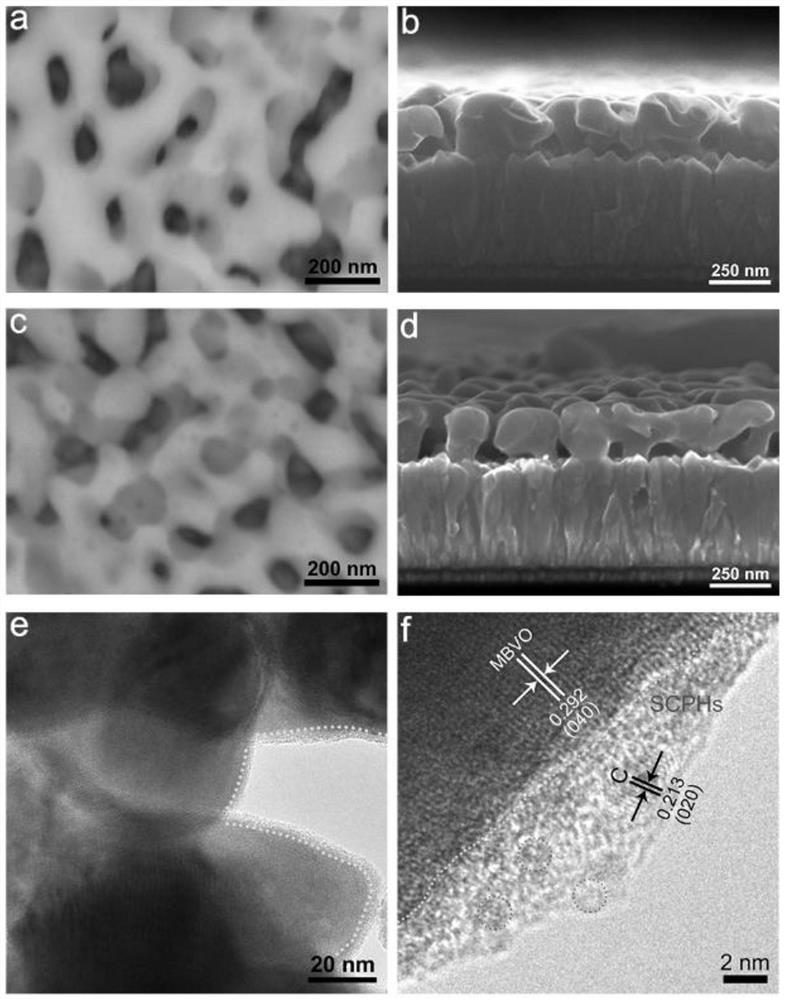

[0040] A Mo:BiVO Modified by Hydroxyl-functionalized Carbon Dots Based on Tannic Acid 4 Thin films, including Mo:BiVO 4 Thin films and modifications on Mo:BiVO 4 Hydroxyl-functionalized carbon dots on the surface of the film, hydroxyl-functionalized carbon dots on Mo:BiVO modified with hydroxyl-functionalized carbon dots 4 The thickness of the film surface was 4 nm.

[0041] Concrete preparation method comprises the following steps:

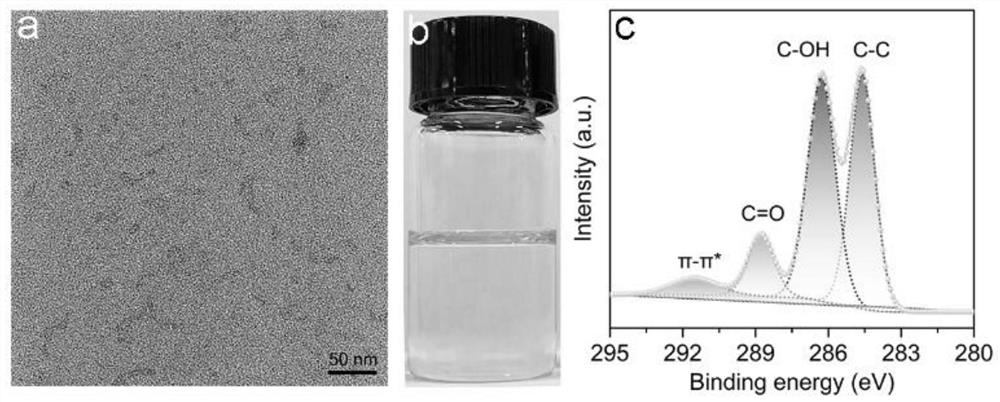

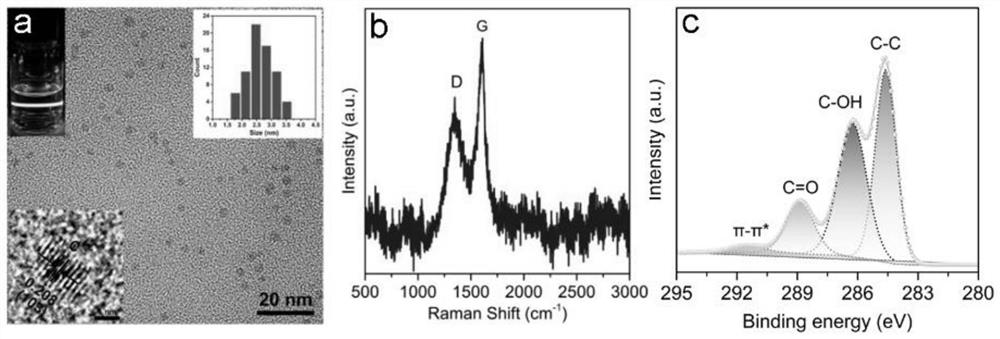

[0042] Step 1, 10 mg of tannic acid powder is dispersed in 10 ml of acetone to obtain a mixed solution;

[0043] Step 2: Ultrasonic pretreatment of the mixed solution for 30 minutes, and then the mixed solution is irradiated under a non-focused laser beam for reaction. During the reaction, ultrasonic assistance is used to fully proceed the reaction; the pulse frequency of the non-focused laser is 10 Hz, and the output The wavelength is 355nm, the output spot diameter is 10mm, and the single pulse energy is 650mJ / cm 2 , after irradiating for ...

Embodiment 2

[0048] A Mo:BiVO Modified by Hydroxyl-functionalized Carbon Dots Based on Tannic Acid 4 Thin films, including Mo:BiVO 4 Thin films and modifications on Mo:BiVO 4 Hydroxyl-functionalized carbon dots on the surface of the film, hydroxyl-functionalized carbon dots on Mo:BiVO modified with hydroxyl-functionalized carbon dots 4 The thickness of the film surface was 4 nm.

[0049] The specific preparation method is exactly the same as that of Example 1, except that 5 mg of tannic acid powder is dispersed in 20 ml of ethanol in Step 1 of Example 2 to obtain a mixed solution.

Embodiment 3

[0051] A Gallic Acid-Based Mo:BiVO Modified by Hydroxy-functionalized Carbon Dots 4 Thin films, including Mo:BiVO 4 Thin films and modifications on Mo:BiVO 4 Hydroxyl-functionalized carbon dots on the surface of the film, hydroxyl-functionalized carbon dots on Mo:BiVO modified with hydroxyl-functionalized carbon dots 4 The thickness of the film surface was 3 nm.

[0052] Concrete preparation method comprises the following steps:

[0053] Step 1, dispersing 8 mg of gallic acid powder in 10 ml of acetone to obtain a mixed solution;

[0054] Step 2: Ultrasonic pretreatment of the mixed solution for 30 minutes, and then the mixed solution is irradiated under a non-focused laser beam for reaction. During the reaction, ultrasonic assistance is used to fully proceed the reaction; the pulse frequency of the non-focused laser is 10 Hz, and the output The wavelength is 355nm, the output spot diameter is 10mm, and the single pulse energy is 450mJ / cm 2 , after irradiating for 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com