Livestock and poultry breeding sterilization nutritional tablet and preparation method thereof

A technology of livestock and poultry breeding and nutritional tablets, which is applied in the field of livestock and poultry breeding feed, can solve the problems of not being able to be used as drinking water for livestock and poultry breeding, poor stability and water solubility of traditional Chinese medicine, and difficult control of traditional Chinese medicine components, so as to promote livestock and poultry breeding. Effects of growth, improvement of egg production performance, and prevention of skin lesions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

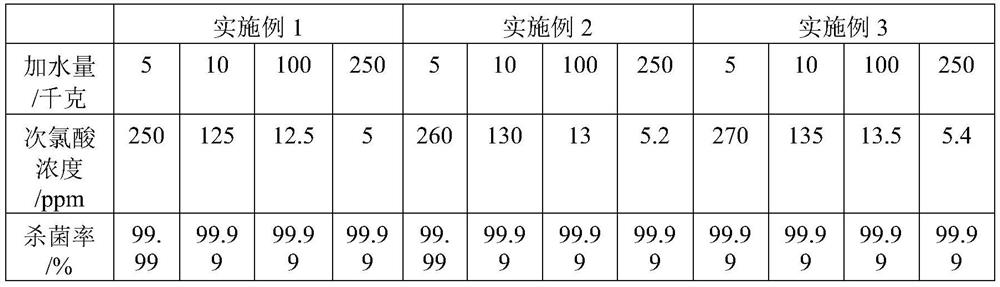

Embodiment 1

[0026] (1) Weigh 0.2g talcum powder and 3g trichloroisocyanuric acid respectively, stir, and mix uniformly for 20-30 minutes to form trichloroisocyanuric acid coated with talcum powder;

[0027] (2) Weigh 0.2g talcum powder and 6g sodium chlorite, stir, mix evenly for 20-30 minutes, form the sodium chlorite coated by talcum powder;

[0028] (3) Under stirring conditions, dissolve 0.6g dextrin and 0.6gL-calcium ascorbate in 1g water, then add 9.4g sodium sulfate to dissolve, continue stirring for 20-30 minutes to obtain a paste, and then add step (1) The prepared talcum powder-coated trichloroisocyanuric acid was uniformly mixed for 30-40 minutes, then dried at 100°C, cooled, ground, and passed through a 100-200 mesh sieve to obtain the mixture;

[0029] (4) Add the talc-coated sodium chlorite in step (2) to the mixture obtained in step (3), and mix evenly for 20-30 minutes, the temperature is 15-25°C, and the humidity is 0-30% R.H., the pressure is 1T / cm 2 Tablets are compre...

Embodiment 2

[0031] (1) Weigh 0.2g talcum powder and 5.6g trichloroisocyanuric acid respectively, stir, and mix evenly for 20-30 minutes to form trichloroisocyanuric acid coated with talcum powder;

[0032] (2) Weigh 0.2g talcum powder and 2g sodium chlorite, stir, mix evenly for 20-30 minutes, form the sodium chlorite coated by talcum powder;

[0033] (3) Under stirring conditions, dissolve 0.2g hydroxypropyl cellulose and 0.6g L-calcium ascorbate in 0.8g water, then add 11.2g sodium sulfate to dissolve, continue stirring for 20-30 minutes to obtain a paste, and then add The talcum powder-coated trichloroisocyanuric acid prepared in step (1) is uniformly mixed for 30-40 minutes, then dried at 100°C, cooled, ground, and passed through a 100-200 mesh sieve to obtain the mixture;

[0034] (4) Add the talc-coated sodium chlorite in step (2) to the mixture obtained in step (3), and mix evenly for 20-30 minutes, the temperature is 15-25°C, and the humidity is 0-30% R.H., pressure 5T / cm 2 Tabl...

Embodiment 3

[0036] (1) Weigh 0.2g talcum powder and 6g trichloroisocyanuric acid respectively, stir, and mix evenly for 20-30 minutes to form trichloroisocyanuric acid coated with talcum powder;

[0037] (2) Weigh 0.2g talcum powder and 1g sodium chlorite, stir, and mix evenly for 20-30 minutes to form talcum powder-coated sodium chlorite;

[0038] (3) Under stirring conditions, dissolve 1g dextrin and 0.4g L-calcium ascorbate in 2g water, then add 11.2g sodium sulfate to dissolve, continue stirring for 20-30 minutes to obtain a paste, and then add step (1) The prepared talcum powder-coated trichloroisocyanuric acid was uniformly mixed for 30-40 minutes, then dried at 100°C, cooled, ground, and passed through a 100-200 mesh sieve to obtain the mixture;

[0039] (4) Add the talc-coated sodium chlorite in step (2) to the mixture obtained in step (3), and mix evenly for 20-30 minutes, the temperature is 15-25°C, and the humidity is 0-30% R.H., pressure 10T / cm 2 Tablets are compressed under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com