Heavy metal chelating agent and preparation method thereof

A heavy metal chelating agent and penetrating agent technology, which is applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of ineffective removal of heavy metals in dust, high energy consumption, and increased landfill volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

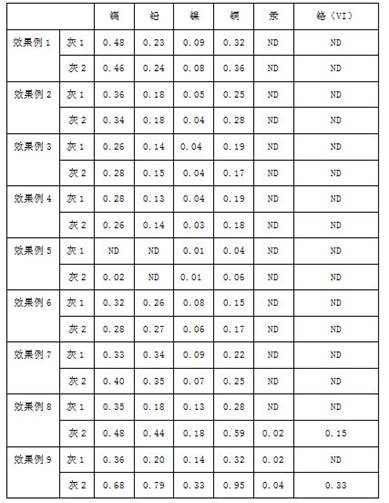

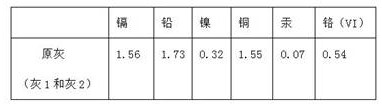

Examples

Embodiment approach

[0020] As a preferred embodiment of the present invention, the dithiocarbamate compound is selected from one of sodium dimethyldithiocarbamate, sodium diethyldithiocarbamate, and sodium dibutyldithiocarbamate or several.

[0021] As a preferred embodiment of the present invention, the polyoxyethylene surfactant is selected from polyoxyethylene octylphenyl ether, polyoxyethylene derivatives, polyoxyethylene desoftened sorbitan monooleate, polyoxyethylene Oxyethylene oxypropylene block polymer, polyoxyethylene lauryl ether, polyoxyethylene monooleate, polyoxyethylene sorbitan monolaurate, polyoxyethylene distyrenated phenyl ether, polyoxyethylene Desoftened sorbitan monostearate, polyoxyethylene sorbitan monopalmitate, polyoxyethylene stearylamine, polyoxyethylene stearyl ether, polyoxyethylene nonylphenyl ether , polyoxyethylene oleyl ether, polyoxyethylene benzyl phenyl ether, polyoxyethylene tribenzyl phenyl ether and other polyoxyethylene type or several.

[0022] As a pre...

Embodiment 1

[0032]Add 28 parts of soft water into the reactor, add 3.5 parts of disodium edetate, 4.0 parts of trisodium citrate dihydrate, raise the reaction temperature to 40 degrees and stir until it is completely dissolved, add dimethyl disulfide 36 parts of sodium carbamate were stirred until completely dissolved and it was about to reach room temperature, 0.8 part of penetrant was added, and 1.0 part of polyoxyethylene octylphenyl ether was mixed uniformly to obtain a metal chelating agent.

Embodiment 2

[0034] Add 28 parts of soft water into the reactor, add 3.5 parts of disodium edetate, 4.0 parts of trisodium citrate dihydrate, raise the reaction temperature to 40 degrees and stir until it is completely dissolved, add dimethyl disulfide Stir 36 parts of sodium carbamate until it is completely dissolved and it will reach room temperature, add 0.8 part of penetrant, and 1.1 parts of polyoxyethylene octylphenyl ether and mix uniformly to obtain a metal chelating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com