Process and device for producing ammonium sulfite and byproduct ammonium thiosulfate liquid fertilizer

A technology for by-producing ammonium thiosulfate and liquid fertilizers is applied in the preparation of alkali metal sulfites, ammonium salt fertilizers, fertilization devices, etc., and can solve the problems of large pollution, high cost of thiosulfate fertilizers, and complicated processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

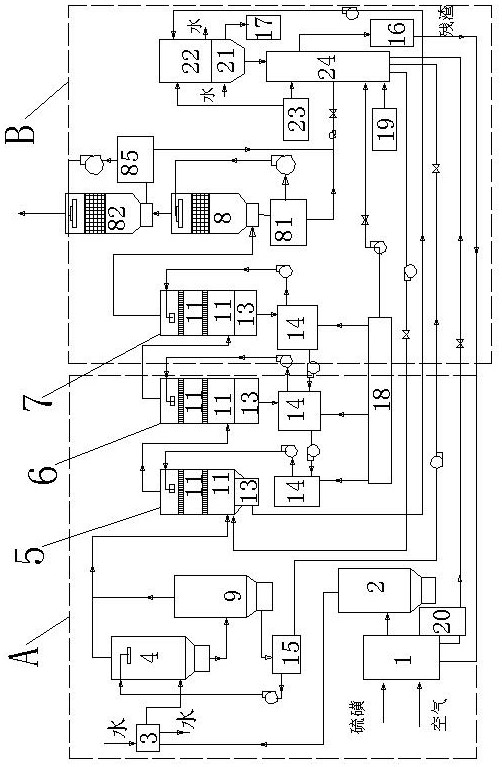

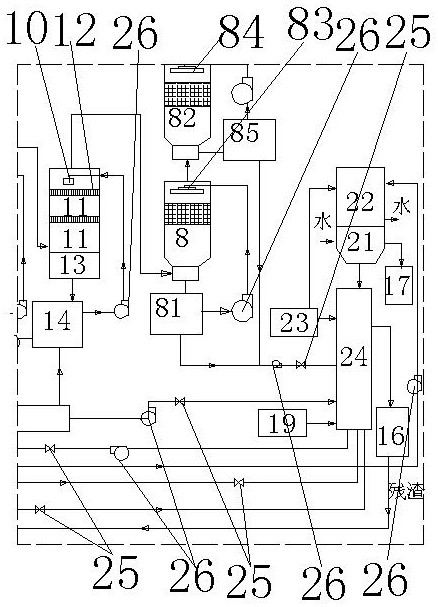

[0066] Example 1. Such as Figure 1-3 Shown, the technique of producing ammonium sulfite and byproduct ammonium thiosulfate liquid fertilizer is characterized in that, comprises the steps:

[0067] Put the waste sulfur into the sulfur incinerator 1 for combustion to produce flue gas rich in high-concentration sulfur dioxide gas; the flue gas enters the cyclone separation tower 2 for dust removal, and the flue gas after dust removal enters the heat exchanger 3 to reduce the temperature to 60~ 70°C; the heat exchanger 3 uses water to cool down. Cyclone separation tower, also called cyclone separator, is a kind of equipment used for the separation of gas-solid system or liquid-solid system. The working principle is to rely on the rotational motion caused by the tangential introduction of the airflow, so that the solid particles or liquid droplets with large inertial centrifugal force are separated from the outer wall. The main features of the cyclone separator are simple struc...

Embodiment 2

[0115] Example 2. Such as Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that the steam generator 20 is used to cool down the sulfur incinerator 1, and when the sulfur incinerator 1 is burned, the temperature of the body of furnace remains at 800 degrees Celsius, and the water produced by the steam generator 20 is The steam is passed into the liquid fertilizer generating kettle 24 so that the temperature of the liquid in the liquid fertilizer generating kettle 24 slowly rises to 65 degrees Celsius within 60 minutes, and the gas generated by the liquid fertilizer generating kettle 24 is passed into the primary absorption tower 5 or the secondary absorption tower 6 Or a three-stage absorption tower 7 . Continue to pass water vapor into the liquid fertilizer generating kettle 24 to make the liquid temperature in the liquid fertilizer generating kettle 24 to 105 degrees Celsius, keep the pressure of the liquid fertilizer generating kettle 24 at 0...

Embodiment 3

[0116] Example 3. Such as Figure 6-10 As shown, the difference between this embodiment and Embodiment 1 is that the steam generator 20 is used to cool down the sulfur incinerator 1, and when the sulfur incinerator 1 is burned, the temperature of the body of furnace remains at 780 degrees Celsius, and the water produced by the steam generator 20 is kept at 780 degrees Celsius. The steam is passed into the liquid fertilizer generating kettle 24 so that the temperature of the liquid in the liquid fertilizer generating kettle 24 slowly rises to 65 degrees Celsius within 60 minutes, and the gas generated by the liquid fertilizer generating kettle 24 is passed into the primary absorption tower 5 or the secondary absorption tower 6 Or a three-stage absorption tower 7 . Continue to pass water vapor into the liquid fertilizer generating still 24 to make the liquid temperature in the liquid fertilizer generating still 24 to 105 degrees Celsius, keep the pressure of the liquid fertiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com