Preparation method of graphene oxide-loaded asphalt-based activated carbon composite material

A composite material and graphene technology, applied in chemical instruments and methods, coking carbonaceous materials, petroleum industry, etc., can solve the problems of unfavorable stirring, difficulty in graphene oxide loading, high viscosity, etc., to improve thermal conductivity and pore size distribution Uniform, energy-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A pitch-based activated carbon composite material loaded with graphene oxide, consisting of 100g deionized water, 15g pitch particles, 45gKOH, 0.15g coupling agent, 0.48g emulsifier, 0.0075g dispersant and 0.015g graphene oxide.

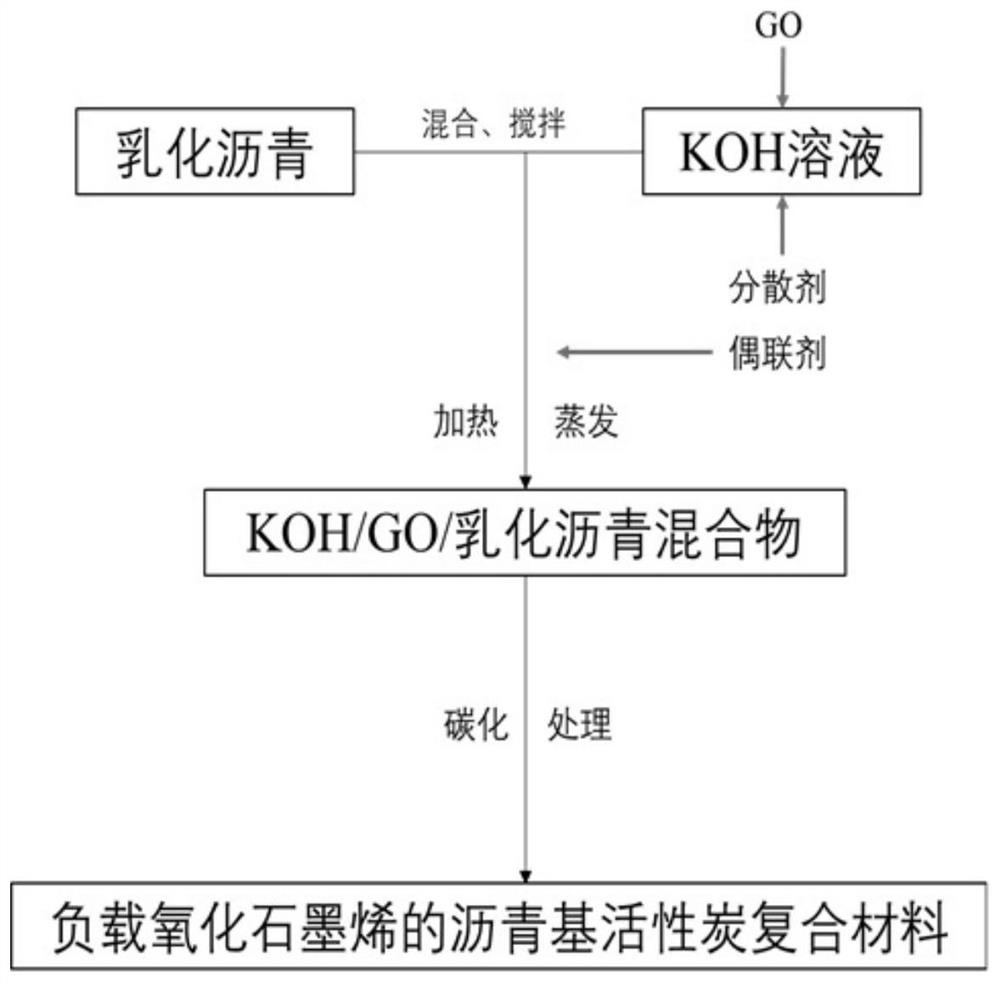

[0032] Preparation method: as figure 1 As shown, the emulsifier, asphalt, and water are selected according to the above contents, and the emulsified asphalt with good performance is prepared at a temperature of 55°C. Dissolving KOH in distilled water, and then adding the dissolved KOH aqueous solution to graphene oxide and a dispersant to prepare a stable dispersion containing an activator. Then mix it with emulsified asphalt, add coupling agent, stir and heat until viscous KOH / GO / emulsified asphalt mixture is obtained. Put the prepared KOH / GO / emulsified asphalt mixture into a tube-type resistance furnace, pass high-purity nitrogen into the furnace, make the entire carbonization environment in a nitrogen atmosphere, set the heating rate of 5°...

Embodiment 2

[0034] A pitch-based activated carbon composite material loaded with graphene oxide, consisting of 100g deionized water, 15g pitch particles, 45gKOH, 0.15g coupling agent, 0.48g emulsifier, 0.0075g dispersant and 0.03g graphene oxide.

[0035] Preparation method: Select emulsifier, asphalt, and water according to the above content, and prepare emulsified asphalt with good performance at a temperature of 60°C. Dissolving KOH in distilled water, and then adding the dissolved KOH aqueous solution to graphene oxide and a dispersant to prepare a stable dispersion containing an activator. Then mix it with emulsified asphalt, add coupling agent, stir and heat until viscous KOH / GO / emulsified asphalt mixture is obtained. Put the prepared KOH / GO / emulsified asphalt mixture into a tube-type resistance furnace, pass high-purity nitrogen into the furnace, make the entire carbonization environment in a nitrogen atmosphere, set the heating rate of 5°C / min for heating, and raise the temperatur...

Embodiment 3

[0037] A pitch-based activated carbon composite material loaded with graphene oxide, consisting of 100g deionized water, 15g pitch particles, 45gKOH, 0.15g coupling agent, 0.48g emulsifier, 0.0075g dispersant and 0.075g graphene oxide.

[0038]Preparation method: Select emulsifier, asphalt, and water according to the above contents, and prepare emulsified asphalt with good performance at a temperature of 58°C. Dissolving KOH in distilled water, and then adding the dissolved KOH aqueous solution to graphene oxide and a dispersant to prepare a stable dispersion containing an activator. Then mix it with emulsified asphalt, add coupling agent, stir and heat until viscous KOH / GO / emulsified asphalt mixture is obtained. Put the prepared KOH / GO / emulsified asphalt mixture into a tube-type resistance furnace, pass high-purity nitrogen into the furnace, make the entire carbonization environment in a nitrogen atmosphere, set the heating rate of 5°C / min for heating, and raise the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com