Nano-micro composite sphere as well as preparation method and application thereof

A composite ball, nano-micro technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problem of not having to separate individual virus particles or direct separation of trace proteins, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a preparation method of nano-micro composite spheres, specifically as follows:

[0033] 1. Main materials:

[0034] A commercially available 2-inch, 50 μm thick double-sided polished silicon wafer is used as the chip substrate; the diameter of the microsphere is 5 μm, polystyrene material, the inside of the ball contains nano-magnetic particles, and there is no residual magnetism after removing the external magnetic field; the diameter of the nanosphere is 1300nm, two Silicon oxide material, surface amination modification.

[0035] 2. Preparation process:

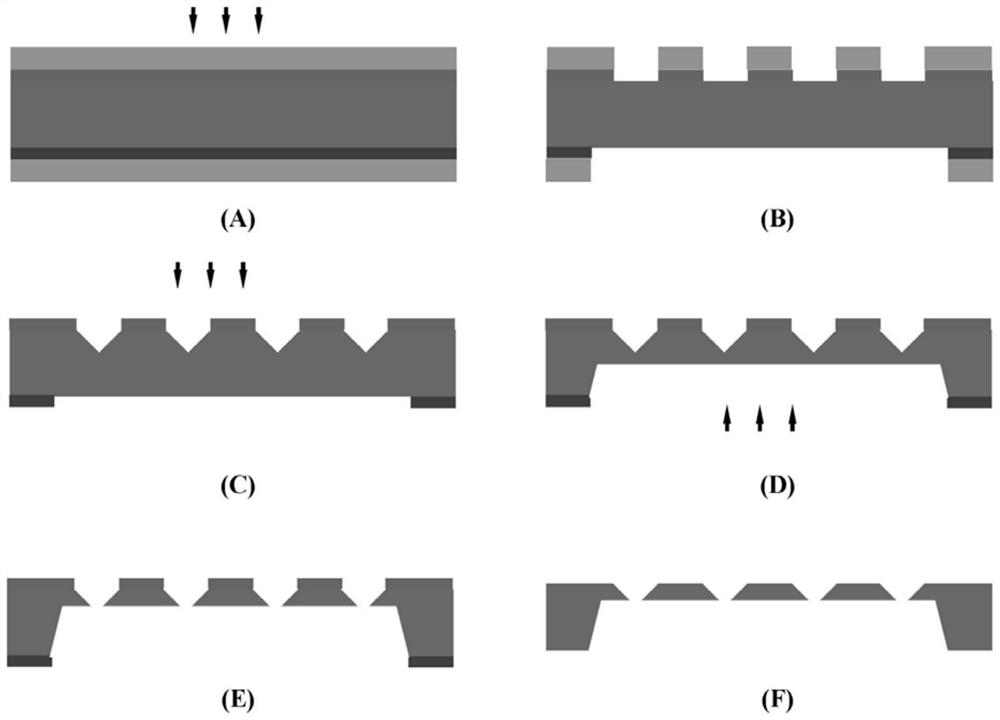

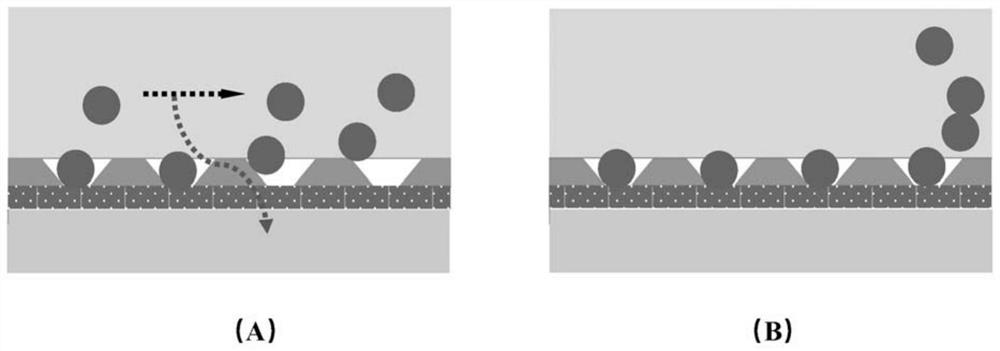

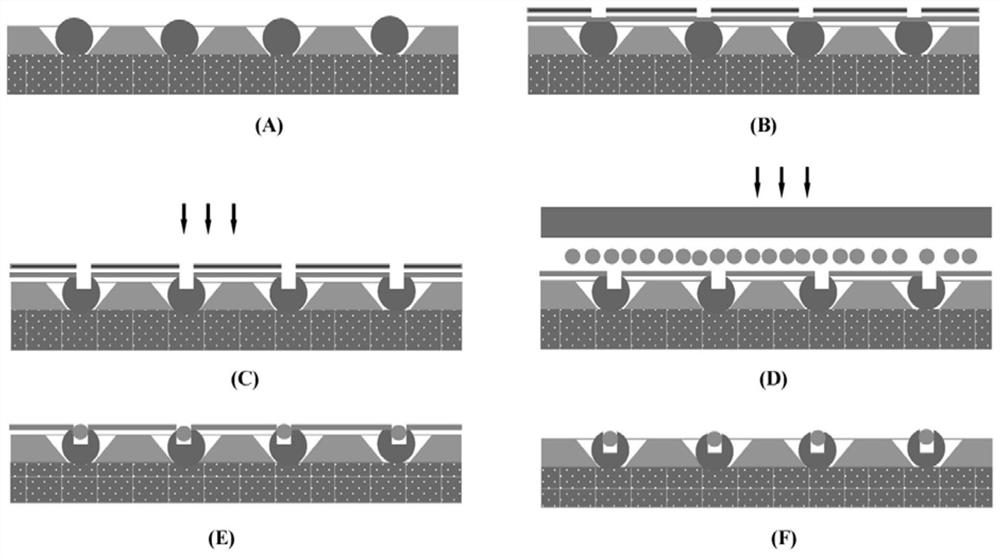

[0036] (1) Prepare a chip containing a micrometer hole in a tapered hole array;

[0037] The tapered micro-hole chip is prepared by double-sided etching method, and the etching process is as follows: figure 1 shown. A Cr mask layer with a thickness of 300nm was formed on the front of the silicon wafer by ion sputtering, and a layer of Si with a thickness of 300nm was formed on the back of...

Embodiment 2

[0047] This embodiment provides a preparation method of nano-micro composite spheres, specifically as follows:

[0048] 1. Main materials:

[0049] Commercially available porous ceramics are used as the chip substrate, with a thickness of 3mm, an average filter pore size of 0.45-0.8μm, a microsphere diameter of 2μm, polystyrene material, nano-magnetic particles inside the ball, a nanosphere diameter of 100nm, a silicon dioxide material, and a surface Amino modification.

[0050] 2. Preparation process:

[0051] (1) Prepare a chip containing a micrometer hole in a tapered hole array;

[0052] Cylindrical microporous chips were prepared by dry etching, and the etching process was as follows: Figure 4 shown. First, if Figure 4 Shown in (A), on the porous ceramic surface, sputter once dense silicon dioxide thin film, thickness 50nm, adopt spin coating method to coat one deck photoresist evenly on dense silicon dioxide thin film, then as shown Figure 4 As shown in (B), the...

Embodiment 3

[0062] This embodiment provides a preparation method of nano-micro composite spheres, specifically as follows:

[0063] 1. Main materials:

[0064] Commercially available porous ceramics are used as the chip substrate, with a thickness of 3mm, an average filter pore size of 0.45-0.8μm, a microsphere diameter of 2μm, polystyrene material, nano-magnetic particles inside the ball, a nanosphere diameter of 100nm, a silicon dioxide material, and a surface Amino modification.

[0065] 2. Preparation process:

[0066] (1) Prepare a chip containing a micrometer hole in a tapered hole array;

[0067] Cylindrical microporous chips were prepared by dry etching, and the etching process was as follows: Figure 4 shown. First, on the porous ceramic surface, sputter a dense silicon dioxide film with a thickness of 50nm, apply a layer of photoresist evenly on the dense silicon dioxide film by spin coating, and use the photolithography process to make the mask plate The circular hole patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com