Method for extracting pure diatom shells from marine single-cell diatom

A technology of pure diatom frustules and single cells, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of cumbersome operation process, mutual adhesion, broken shell, etc., and achieve simple operation process, simple operation process, and shell structure full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: purify Cyclotella shell

[0038] The above-mentioned cultivated Cyclotella cryptica ( Cyclotella cryptica ) into 100 mL centrifuge tubes, put them into a centrifuge for centrifugation after balancing, the centrifugal force is 2000 g, and the centrifugation time is 5 min. After the centrifugation is completed, discard the supernatant, combine the diatom mud in each tube, and wash with distilled water 3 times to remove inorganic salts and some impurities. Add 25 mL of concentrated sulfuric acid to the algae mud as a treatment solution to fully mix the algae cells with concentrated sulfuric acid, and place them in a water bath at 60°C for 45 min. The heated mixture was left at room temperature for 24 h; an equal volume of concentrated nitric acid was added to the mixture again, heated at 60°C until clear, and left at room temperature for 24 h. The treated diatom shells were collected by natural filtration through a sieve to avoid damage to the diatom shell...

Embodiment 2

[0044] Embodiment 2: Purification Thalassiosira wischii shell

[0045] The above-mentioned cultivated Thalassiosira wilsonii ( Thalassiosira weissflogii ) into 100 mL centrifuge tubes, and put them into a centrifuge for centrifugation with a centrifugal force of 2000 g and a centrifugation time of 5 minutes. After the centrifugation is completed, discard the supernatant, combine the algae mud in each tube, and wash 3 times with distilled water. The method for extracting pure diatom frustules is the same as in Example 1.

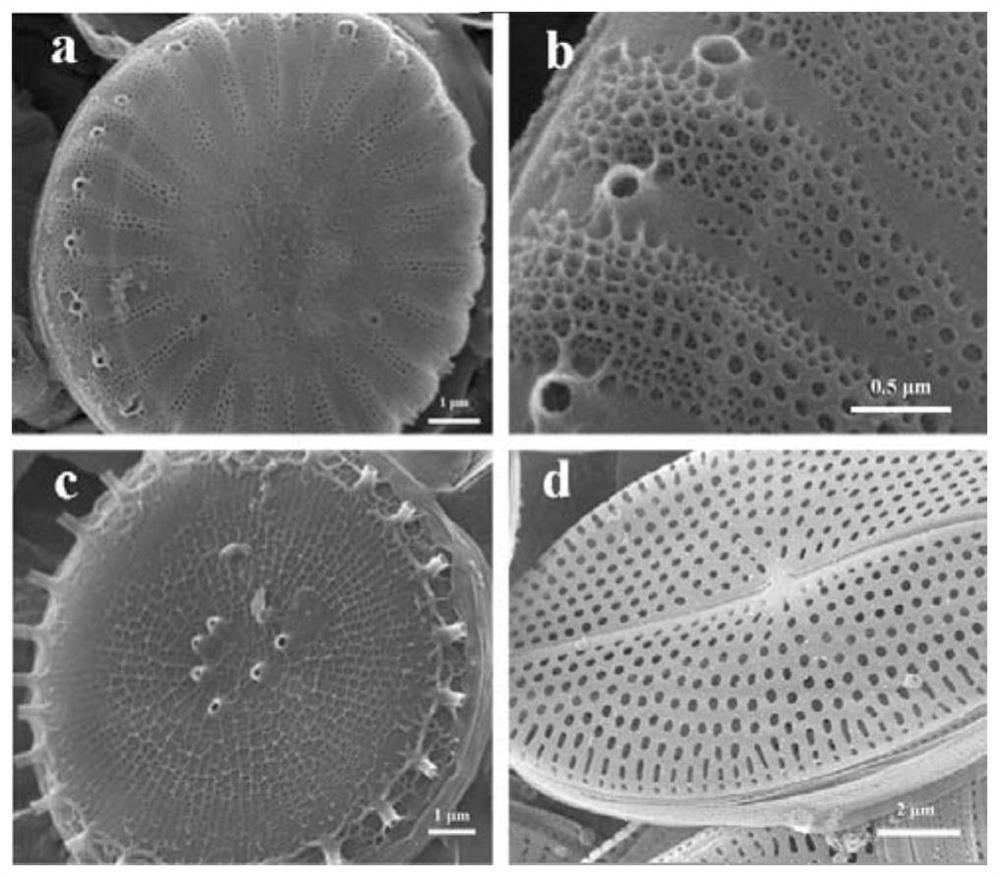

[0046] Stick the diatom frustule of Thalassiosira wilsonii on the double-sided tape, and spray gold on it, figure 1 It is a scanning electron microscope picture of Thalassiosira wilsonii. The results show that the shell structure of Thalassiosira wilsonii is complete, the pore size is transparent, and there is no organic matter residue ( figure 1 c).

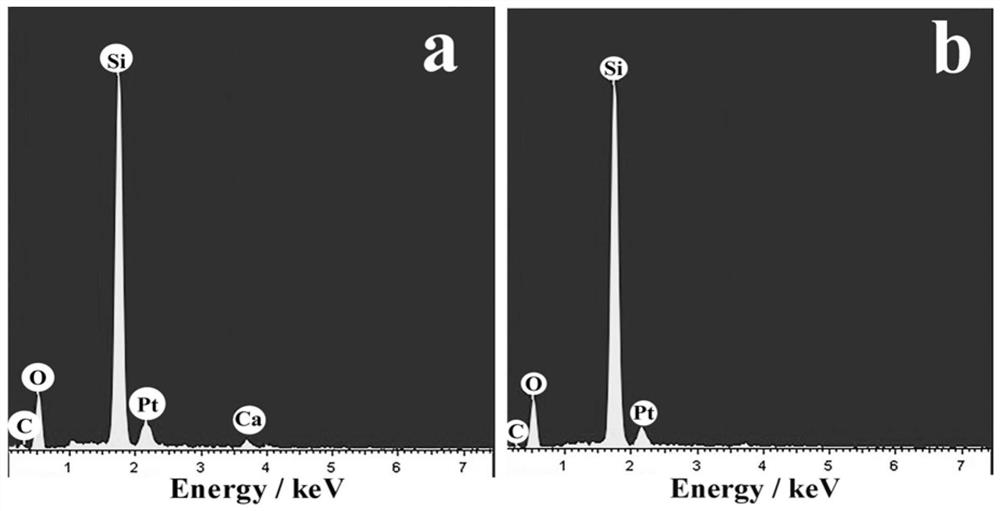

[0047] figure 2 It is the result of energy spectrum analysis of Thalassiosira wilsonii, by figure...

Embodiment 3

[0050] Embodiment 3: purify ovale shell

[0051] The above-mentioned cultivated ovoid algae ( Cocconeiopsis orthoneoides ) with a 2500-mesh sieve to collect the algae cells and wash them three times with distilled water to remove inorganic salts and some impurities. The method for extracting ovale diatom frustules is the same as in Example 1. Through scanning electron microscopy (SEM) morphology analysis and energy dispersive X-ray spectrometer (EDXS) analysis of the extracted samples, the main components of diatom frustules were quantitatively analyzed with an elemental analyzer.

[0052] figure 1 It is a scanning electron microscope image of the ovoid algae shell, and the results show that the structure of the ovoid algae diatom shell obtained by the present invention is complete, the original shape and microstructure of the shell are retained, and there is no organic matter residue.

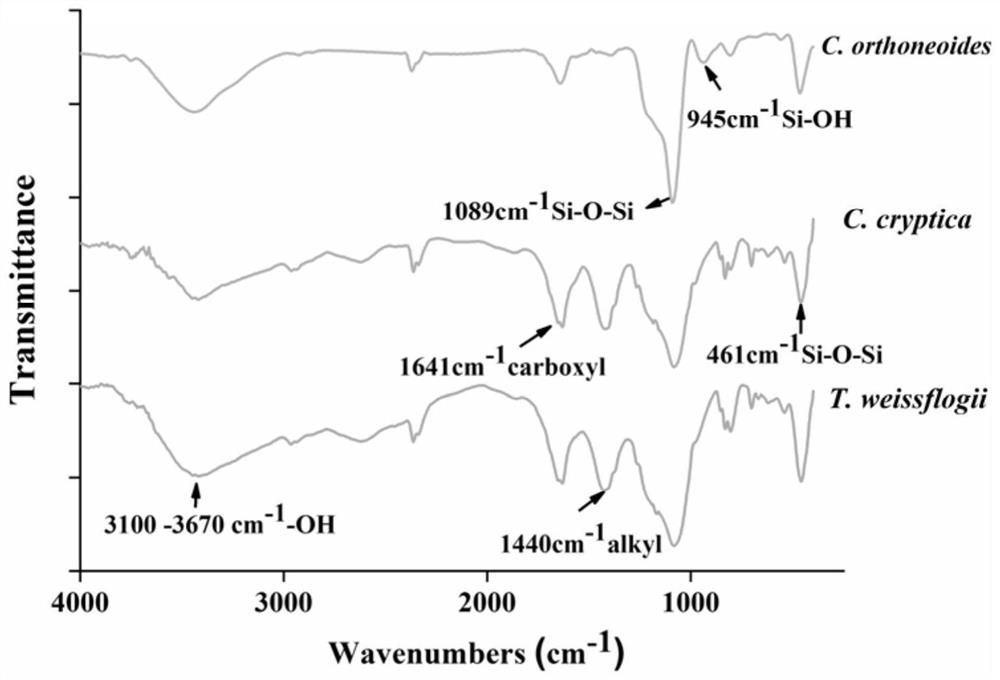

[0053] image 3 It is the infrared spectrogram of ovale algae. The results show that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com