Electrolysis/ultraviolet device for treating chemical nickel plating wastewater

A technology of electroless nickel plating and ultraviolet device, applied in the direction of water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve the problems of easy pollution of ultraviolet lamp tubes, unstable treatment effect, high operating cost, etc., and achieve avoidance Decrease in effect, prevent fouling, and reduce cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

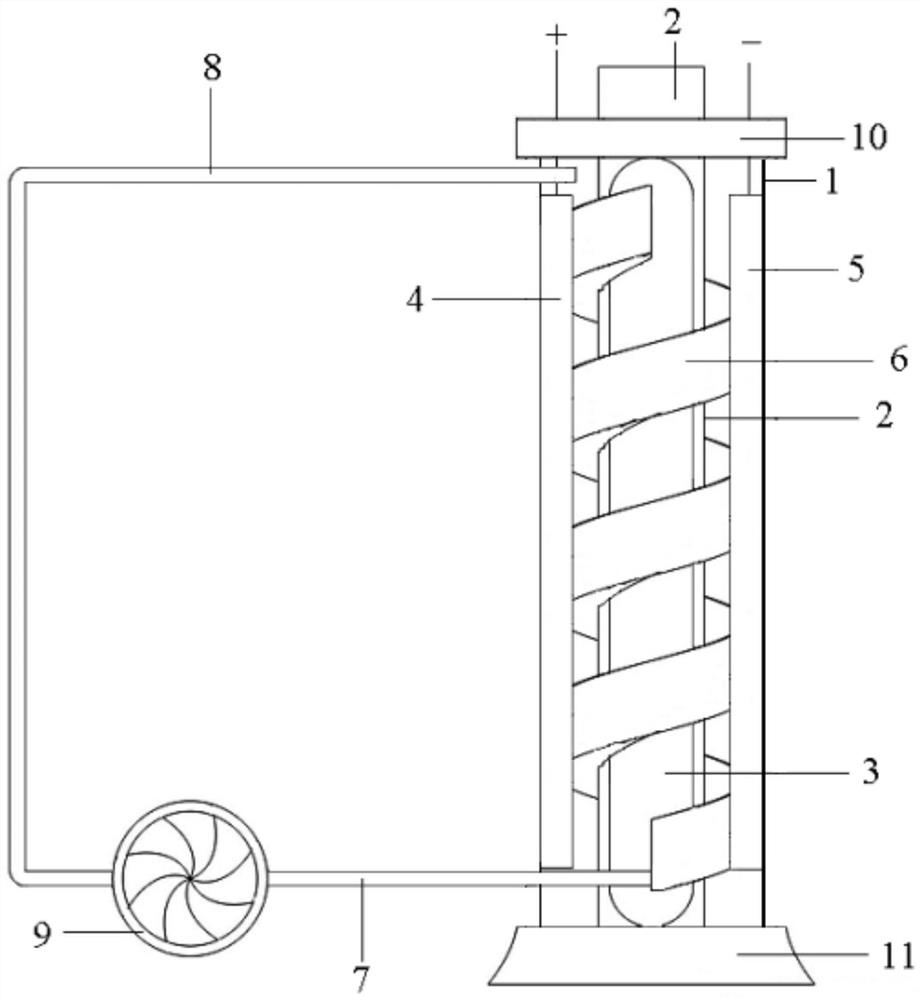

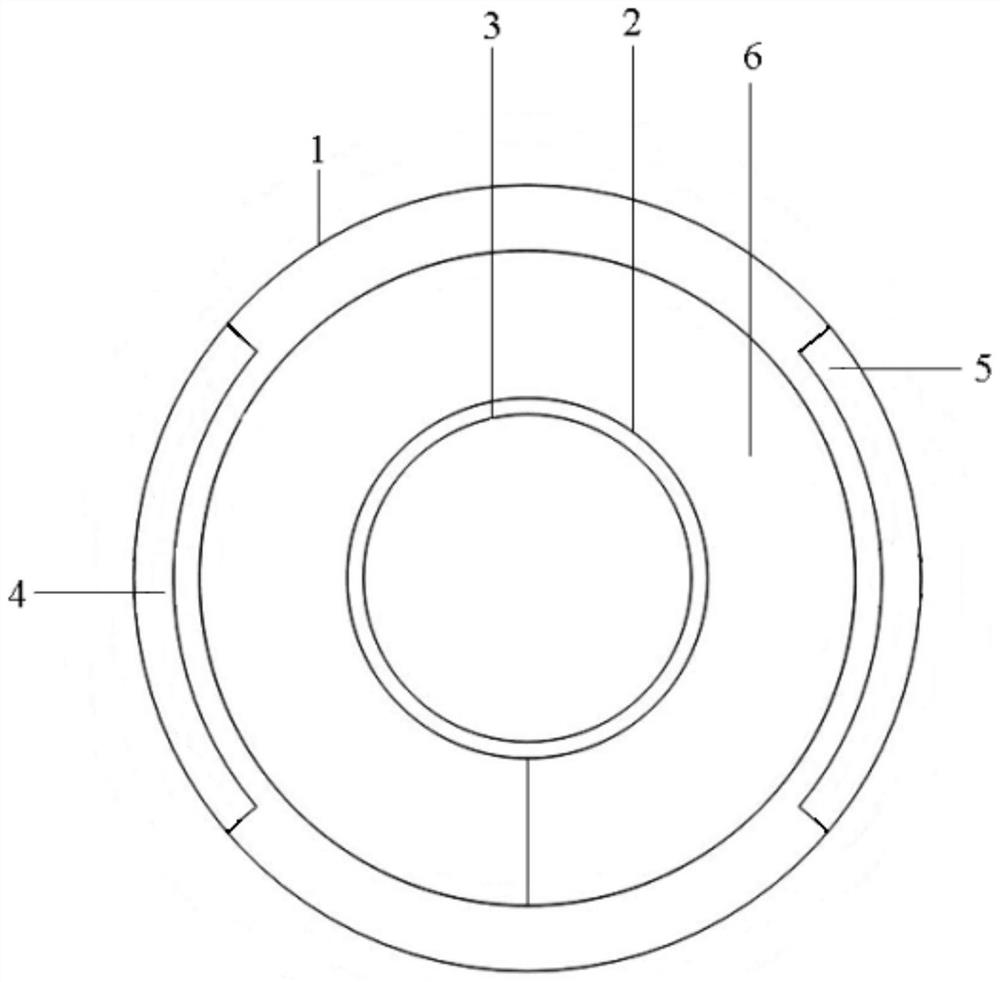

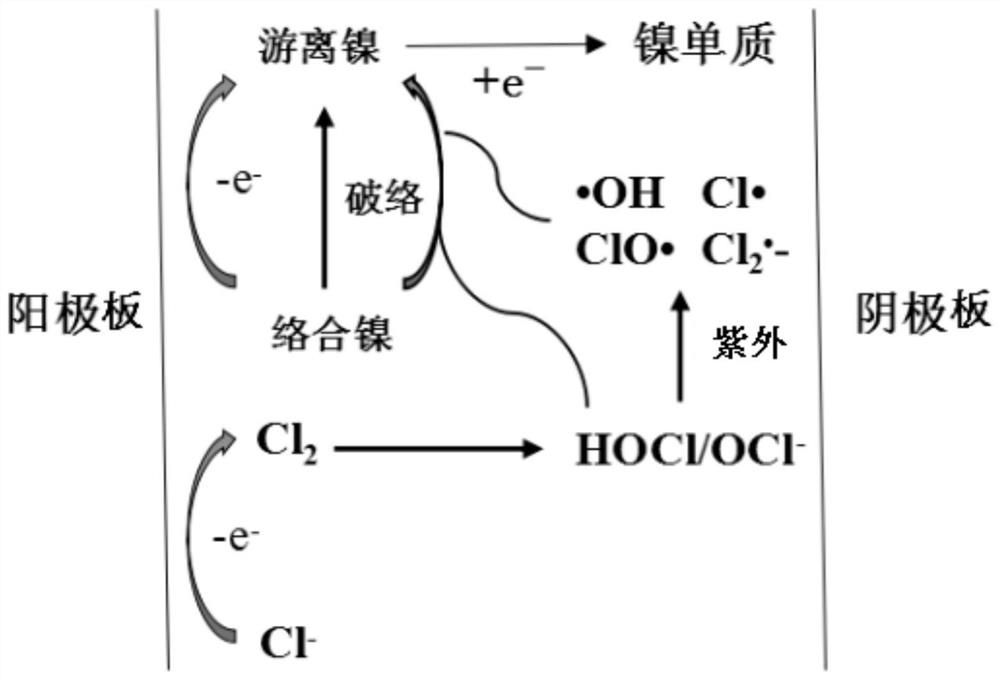

[0022] Specific embodiment one: this embodiment is an electrolysis / ultraviolet device for treating chemical nickel plating wastewater, such as Figure 1-Figure 2 As shown, it is specifically composed of electrolytic cell 1, quartz glass tube 2, ultraviolet lamp tube 3, anode plate 4, cathode plate 5, spiral slide 6, water inlet pipe 7, water outlet pipe 8, circulating water pump 9, upper cover 10 and base 11 composition;

[0023] The electrolytic cell 1 is a hollow cylinder structure, and the top is provided with a cover 10 to form a closed inner cavity, and the bottom is provided with a base 11; the quartz glass tube 2 is vertically fixed at the center of the inner bottom surface of the electrolytic cell 1, and The top of the quartz glass tube 2 extends to the top of the upper cover 10 through the upper cover 10, and the top of the quartz glass tube 2 is an open structure; the ultraviolet lamp tube 3 is vertically arranged inside the quartz glass tube 2;

[0024] The spiral ...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that: the electrolytic cell 1 is made of organic glass. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the anode plate 4 is a titanium-based ruthenium-iridium electrode. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com