A kind of fast thermal response super black material and preparation method thereof

An ultra-black material and fast heating technology, which is applied in the metal material coating process, superimposed layer coating, vacuum evaporation coating, etc., can solve the problems such as no ultra-black coating materials, and achieve the guarantee of spectral absorption and Effect of emission, high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

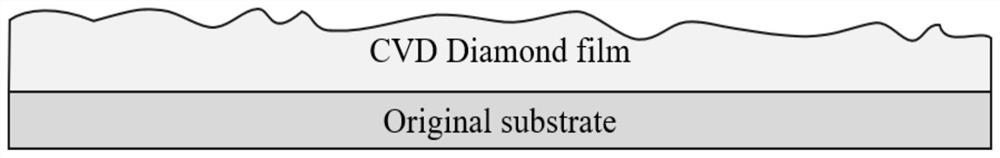

[0029] 1. Select a polished single-crystal Si substrate with a size of 10 × 10 (mm), use diamond powder grinding to assist alcohol cleaning to process the sample, and then dry it and put it into a chemical vapor deposition system;

[0030] 2. A microwave plasma CVD system is used to coat a diamond film on the surface of the above-mentioned silicon wafer. A typical deposition process is: working gas hydrogen / methane, power 2.8-3.0kW, substrate temperature 800°C, methane concentration 3%, and deposition time 100h. The actual deposition thickness is about 260-280μm;

[0031] 3. Grinding and polishing the diamond film with a substrate, the surface roughness Ra of the diamond film reaches 50nm, and the film thickness is approximately 200±20μm;

[0032] 4. The "silicon / diamond" structure in step 3 is treated in 80% HF acid to remove the silicon wafer substrate.

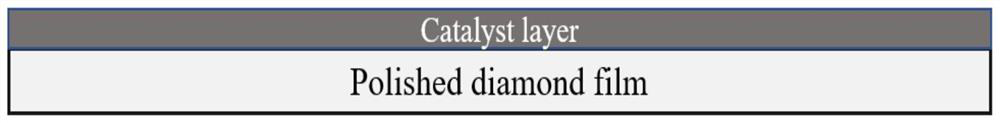

[0033] 5. Using radio frequency magnetron sputtering technology, a layer of catalytic metal layer is formed by sputteri...

Embodiment 2

[0037] 1. Select a graphite substrate with a diameter of φ100mm, use diamond powder grinding to assist alcohol cleaning to process the sample, and then dry it and put it into a chemical vapor deposition system;

[0038] 2. Using a DC jet CVD system to prepare a diamond film on the surface of the substrate. A typical deposition process is: working gas hydrogen / methane, power of about 22kW, substrate temperature of about 900°C, methane concentration of 10%, and deposition time of 180h. The actual deposition thickness is about 1.5mm;

[0039] 3. Grinding and polishing the diamond film with substrate, the surface roughness Ra of the diamond film reaches 20-100nm, and the film thickness is 1200±100μm;

[0040] 4. Using radio frequency magnetron sputtering technology, a layer of catalytic metal layer is formed by sputtering deposition on the surface of the diamond film that has been ground and polished in step 3. The target material is a 99.99% Ni target with a vacuum degree of 5×...

Embodiment 3

[0044] 1. Select a graphite substrate with a diameter of φ100mm, use diamond powder grinding to assist alcohol cleaning to process the sample, and then dry it and put it into a chemical vapor deposition system;

[0045] 2. A diamond film is prepared on the surface of the above-mentioned substrate by DC spray CVD technology. A typical deposition process is: working gas hydrogen / methane, power of about 22kW, substrate temperature of about 900°C, methane concentration of 10%, and deposition time of 180h. The actual deposition thickness is about 1.5mm;

[0046] 3. Grinding and polishing the diamond film with substrate, the surface roughness Ra of the diamond film reaches 20-100nm, and the film thickness is 1200±100μm;

[0047] 4. Using radio frequency magnetron sputtering technology, a layer of catalytic metal layer is formed by sputtering deposition on the surface of the diamond film that has been ground and polished in step 3. The target material is Fe target with a purity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com