High-dispersion nickel inner electrode slurry for multilayer chip ceramic capacitor and preparation method of high-dispersion nickel inner electrode slurry

A technology of multilayer chip ceramics and capacitors, applied in fixed capacitor electrodes, laminated capacitors, fixed capacitor dielectrics, etc., can solve problems such as discontinuity, limited dispersion of nano-powders, and influence on the electrical properties of MLCC products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

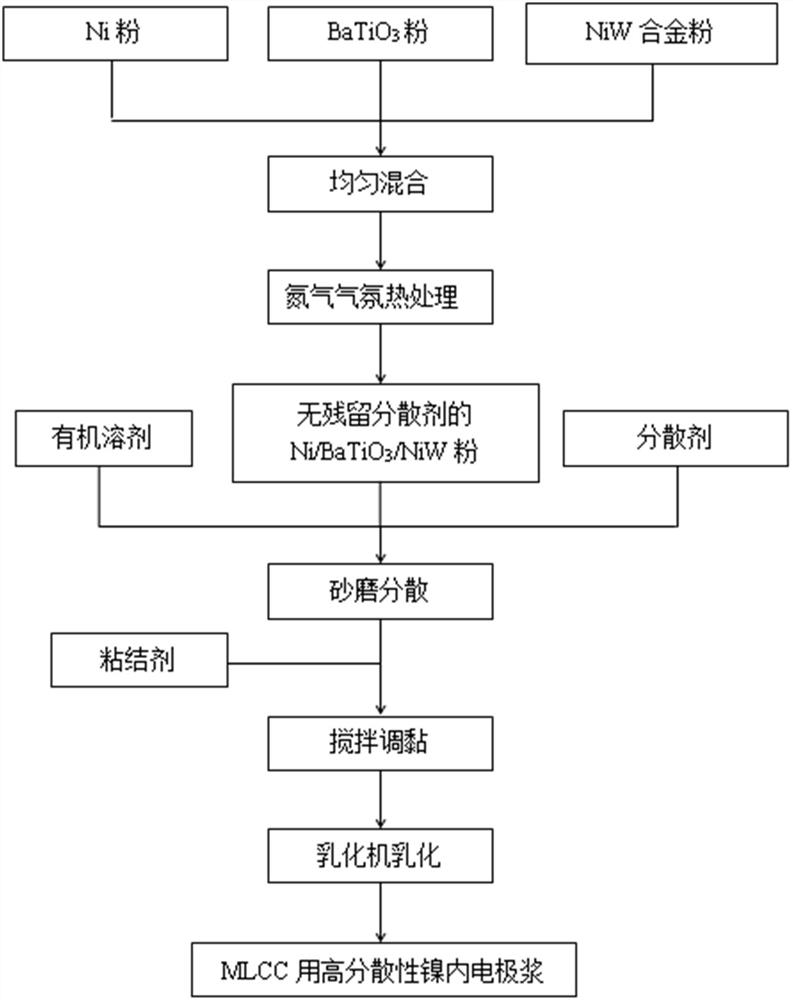

[0046] Based on the above findings, the present invention provides a method for preparing a nickel internal electrode slurry for MLCC, comprising the following steps:

[0047] (1) Ni powder without residual dispersant, BaTiO without residual dispersant 3 Powder, organic solvent, dispersant and NiW alloy powder preferably added without residual dispersant are mixed evenly to obtain slurry A;

[0048] (2) Use a sand mill to sand slurry A to obtain slurry B;

[0049] (3) Add binder to slurry B, mix evenly to obtain slurry C;

[0050](4) Use an emulsifier to emulsify the slurry C to obtain a nickel internal electrode slurry for MCC.

[0051] In the present invention, for preparing the Ni powder of slurry A, BaTiO 3 Powder and NiW alloy powder do not contain residual dispersant. In the production of Ni powder, BaTiO 3 Dispersants are usually used in the process of Ni powder and NiW alloy powder, resulting in Ni powder, BaTiO 3 Powder and NiW alloy powder products contain a ce...

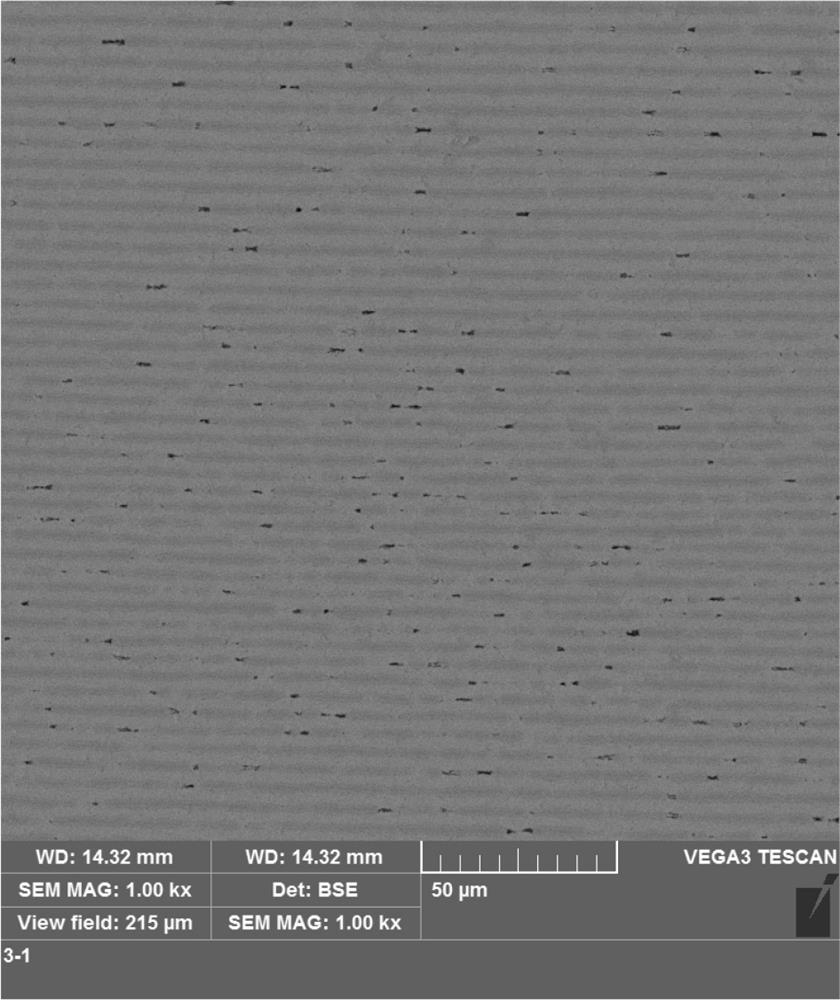

Embodiment 1

[0085] This embodiment prepares a highly dispersible nickel internal electrode slurry for MLCC, which specifically includes the following steps:

[0086] (1) Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder preparation:

[0087] Ni powder, BaTiO 3 Powder and NiW alloy powder are mixed uniformly by a mixer to obtain Ni / BaTiO 3 / NiW homogeneous powder, among them, Ni powder and BaTiO 3 The mass ratio of powder is 1:0.12, and the mass fraction of NiW alloy powder is Ni powder and BaTiO 3 0.5% of the total weight of powder. Ni / BaTiO 3 / NiW homogeneous powder was heat-treated at 300°C for 4 hours in a nitrogen atmosphere rotary furnace to obtain Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder.

[0088] (2) Sanding dispersion:

[0089] Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder, organic solvent and dispersant to adjust to Ni / BaTiO with a solid content of 40% 3 / NiW slurry, wherein the mass fraction of dispersant is Ni / BaTiO ...

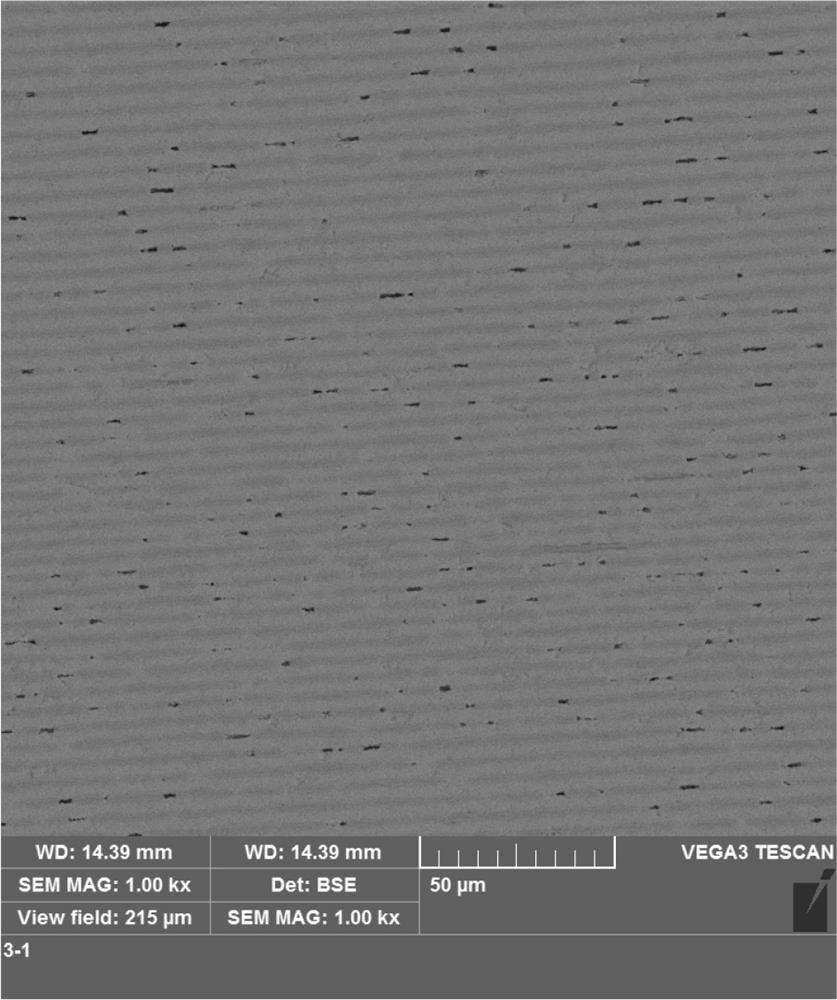

Embodiment 2

[0095] This embodiment prepares a highly dispersible nickel internal electrode slurry for MLCC, which specifically includes the following steps:

[0096] (1) Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder preparation:

[0097] Ni powder, BaTiO 3 Powder and NiW alloy powder are mixed uniformly by a mixer to obtain Ni / BaTiO 3 / NiW homogeneous powder, among them, Ni powder and BaTiO 3 The mass ratio of powder is 1:0.28, and the mass fraction of NiW alloy powder is Ni powder and BaTiO 3 1% of the total weight of powder. Ni / BaTiO 3 / NiW homogeneous powder was heat-treated at 400°C for 3 hours in a nitrogen atmosphere rotary furnace to obtain Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder.

[0098] (2) Sanding dispersion:

[0099] Ni / BaTiO without residual dispersant 3 / NiW homogeneous powder, organic solvent and dispersant to adjust to Ni / BaTiO with a solid content of 50% 3 / NiW slurry, wherein the mass fraction of dispersant is Ni / BaTiO 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com