Cobalt-based monoatomic dehydrogenation catalyst and method for preparing olefin corresponding to paraffin from paraffin by using same

A technology of cobalt-based catalysts and paraffins, which is applied in the field of cobalt-based single-atom dehydrogenation catalysts, which can solve the problems of catalyst activity reduction and achieve suppression of deterioration or denaturation, suppression of cobalt mutual aggregation or sintering, good conversion rate and olefin selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0114] First, 20 g of commercially available silica was dispersed in 200 ml of distilled water, and KOH having a weight of 0.144 g was dissolved, followed by stirring for 30 minutes, thereby preparing a silica aqueous dispersion. Afterwards, 28% by weight of concentrated ammonia water (Samchun Chemical Co.) was added to the aqueous silica dispersion to adjust the pH of the dispersion to 11, thereby preparing a pH-adjusted potassium-treated aqueous silica dispersion. .

[0115] Separately, 5 g of cobalt precursor (Co(NH 3 ) 6 Cl 3 ) was dissolved in 50 ml of distilled water in a beaker, and 28% by weight of concentrated ammonia water (Samchun Chemical Co.) was added to adjust the pH to 11, thereby preparing a pH-adjusted cobalt precursor aqueous solution.

[0116] Then, the pH-adjusted cobalt precursor aqueous solution was quickly added to the pH-adjusted potassium-treated aqueous silica dispersion, and stirred at room temperature for 10 minutes. The stirred sample was allo...

experiment example 1

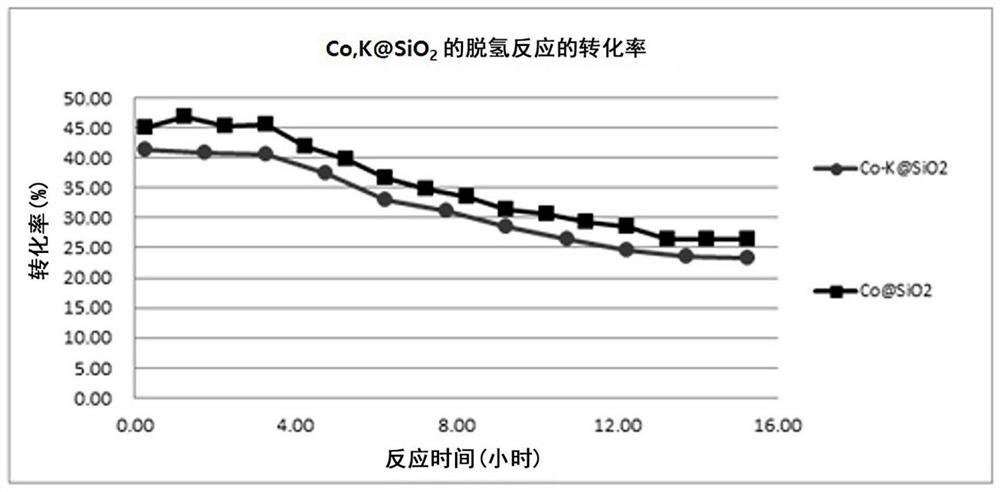

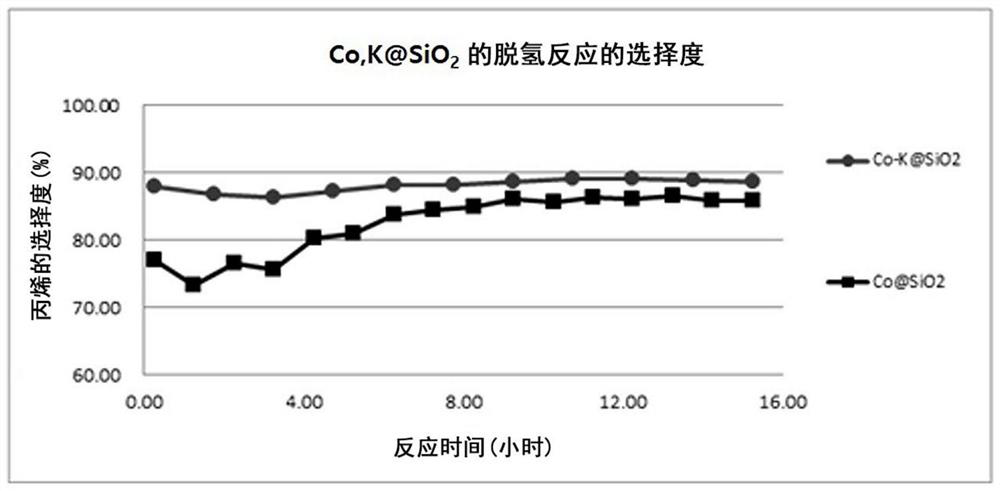

[0131] In this experimental example, a dehydrogenation reaction for synthesizing olefins from a reactant gas containing a high content of paraffin was performed in the presence of the cobalt-based catalysts prepared according to Preparation Example 1 and Comparative Preparation Example 1, respectively.

[0132]The dehydrogenation reactions used to evaluate the catalysts were performed using 3 / 4 inch quartz tube reactors (3 / 4 inch diameter in the catalyst loading area, 1 / 4 inch diameter tubes otherwise). A mass flow controller (Mass Flow Controller) was used to adjust the flow rate of each gas, and the product gas passing through the reactor was analyzed by an online gas chromatography analysis equipment (50m HP-PLOT chromatographic column).

[0133] Weigh the catalyst of 5cc (about 3.3g), and support it in the reaction tube with quartz wool, then make N 2 (99.999%, Taisei Industrial Gas Co., Ltd.) flowed at a flow rate of 100 cc / min, and at the same time raised the temperature...

experiment example 2

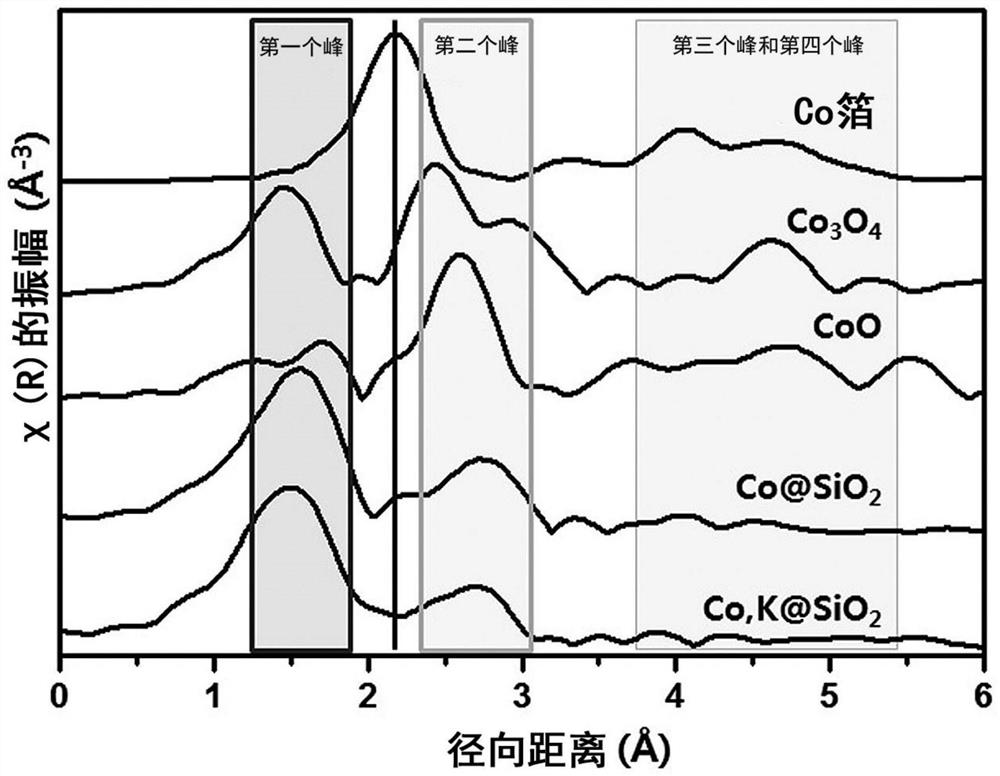

[0139] In this experimental example, in order to confirm the thermal stability of the cobalt-based catalysts prepared according to Preparation Example 1 and Comparative Preparation Example 1, heat treatment at high temperature was performed, specifically, heat treatment was performed at 800° C. for 3 hours in an air atmosphere. Figure 4 The result of observing the change of the catalyst after the heat treatment and the change of the catalyst after performing the propane dehydrogenation reaction in Experimental Example 1 by EXAFS is shown in .

[0140] refer to Figure 4 , as shown in Preparation Example 1, when the monoatomic form of Co was treated with K before being supported on silica, even after the dehydrogenation reaction or heat treatment at high temperature, Co also existed in the monoatomic form, but in the comparative In the case of Preparation Example 1, it can be seen that the state of Co changes after the dehydrogenation reaction or heat treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com