Preparation method of spherical nano cerium dioxide

A nano-cerium dioxide, spherical technology, applied in the field of preparation of nano-CeO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

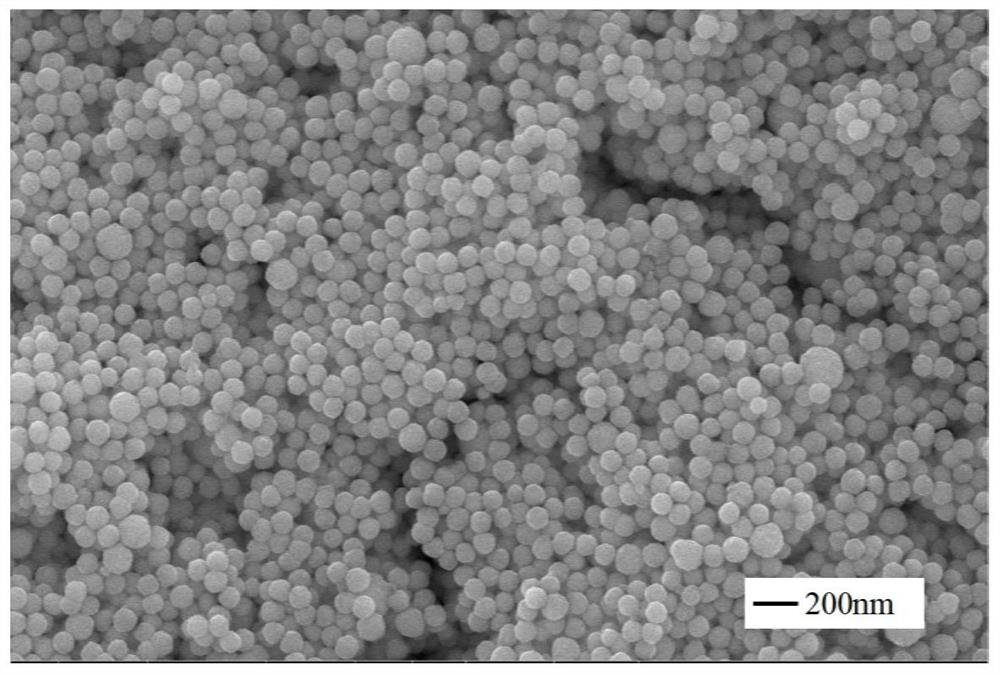

[0040] Spherical nano cerium oxide, the preparation method comprises the following steps:

[0041] 1) Dissolve cerous nitrate hexahydrate (analytically pure) in ethylene glycol to prepare a 0.4mol / L cerous nitrate ethylene glycol solution. Dissolve sodium hydroxide (analytically pure) in ethylene glycol to prepare a sodium hydroxide ethylene glycol solution with a concentration of 1.2mol / L. Under stirring, slowly pour 250ml of sodium hydroxide ethylene glycol solution into 250ml of cerous nitrate ethylene glycol solution, stir at 600rpm for 10min, and a precipitation reaction occurs.

[0042] 2) After the precipitation reaction is completed, add 40 g of hydroxypropyl cellulose (analytical pure) to the reaction system and stir at 600 rpm for 1 h to obtain a reaction mixture.

[0043] 3) Put the reaction mixture obtained in step 2) into an oil bath, continuously inject air into the reaction mixture and stir with a high-speed shear. Among them, the oil bath temperature is 140°C...

Embodiment 2

[0049] Spherical nano cerium oxide, the preparation method comprises the following steps:

[0050] 1) Dissolve cerous nitrate hexahydrate (analytically pure) in ethylene glycol to prepare a 0.7mol / L cerous nitrate ethylene glycol solution. Dissolve sodium hydroxide (analytically pure) in ethylene glycol to prepare a sodium hydroxide ethylene glycol solution with a concentration of 2.1mol / L. Under stirring, slowly pour 250 mL of sodium hydroxide ethylene glycol solution into 250 mL of cerous nitrate ethylene glycol solution, stir at 600 rpm for 10 min, and a precipitation reaction occurs.

[0051] 2) After the precipitation reaction is completed, add 40 g of hydroxypropyl cellulose (analytical pure) to the reaction system and stir at 600 rpm for 1 h to obtain a reaction mixture.

[0052] 3) Put the reaction mixture obtained in step 2) into an oil bath, continuously inject air into the reaction mixture and stir with a high-speed shear. Among them, the oil bath temperature is 1...

Embodiment 3

[0056] Spherical nano cerium oxide, the preparation method comprises the following steps:

[0057] 1) Dissolve cerous nitrate hexahydrate (analytically pure) in ethylene glycol to prepare a 0.3mol / L cerous nitrate ethylene glycol solution. Dissolve sodium hydroxide (analytically pure) in ethylene glycol to prepare a sodium hydroxide ethylene glycol solution with a concentration of 0.9 mol / L. Under stirring, slowly pour 250ml of sodium hydroxide ethylene glycol solution into 250ml of cerous nitrate ethylene glycol solution, stir at 600rpm for 10min, and a precipitation reaction occurs.

[0058] 2) After the precipitation reaction is completed, add 60 g of hydroxypropyl cellulose (analytical pure) to the reaction system and stir at 600 rpm for 1 h to obtain a reaction mixture.

[0059] 3) Put the reaction mixture obtained in step 2) into an oil bath, continuously inject air into the reaction mixture and stir with a high-speed shear. Among them, the oil bath temperature is 140°...

PUM

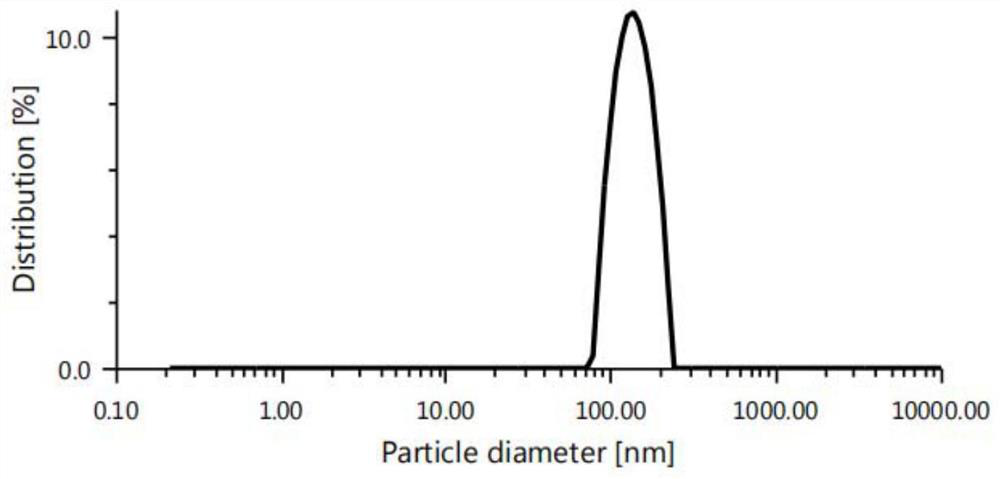

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com