Rare earth molten salt electrolysis fluorine-containing wastewater treatment method

A technology for molten salt electrolysis and wastewater treatment, which is used in water/sewage treatment, neutralized water/sewage treatment, and multi-stage water/sewage treatment. problems, to achieve the effect of saving resources, clarifying water quality, and avoiding sludge bulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

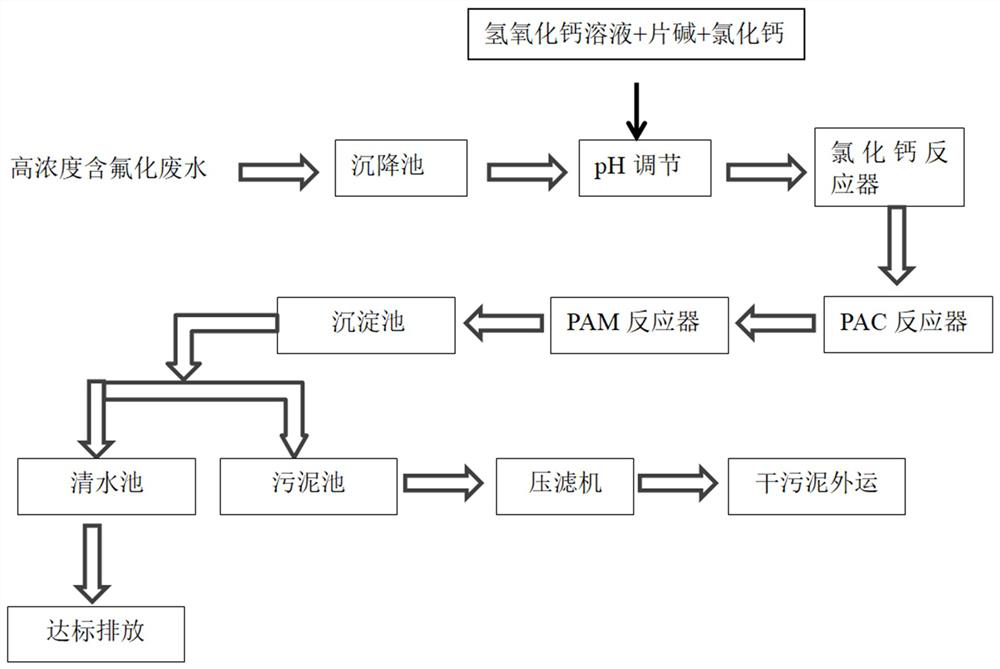

Image

Examples

Embodiment 1

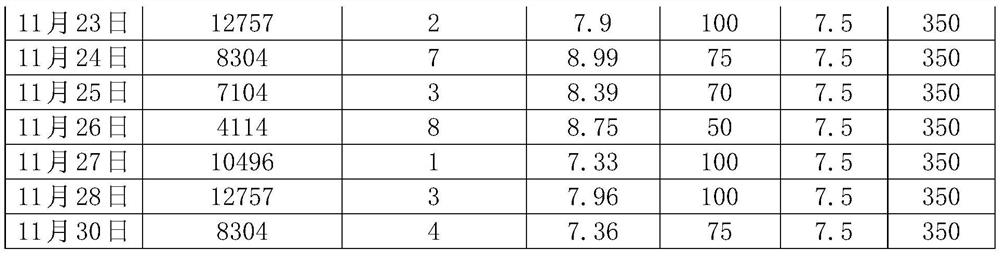

[0041] Fluorine-containing wastewater generated during the production process of the factory: fluoride ion concentration 7681mg / L, pH=3. The daily wastewater treatment capacity is about 10 cubic meters, and the daily operation time is 10 hours. The specific steps of fluorine-containing wastewater treatment are as follows:

[0042] Step 1: Collect fluorine-containing wastewater and send it to a settling tank (capacity of 8 cubic meters) to preliminarily settle the suspended solids in the wastewater and clarify the water quality.

[0043] Step 2: Send the effluent from the sedimentation tank to the pH value regulator, add calcium hydroxide solution and flake sodium hydroxide, the mass concentration of the added calcium hydroxide is 5g / L, add 25kg of caustic soda, add 25kg of calcium chloride solid, Compressed air is passed through the regulator for stirring, and the pressure of the compressed air is greater than 0.2MPa. In order to ensure the full reaction of fluoride ions and...

Embodiment 2

[0049] Fluorine-containing waste water generated during the production process of the factory: fluoride ion concentration 3010mg / L, pH=4.5. The daily wastewater treatment capacity is about 10 cubic meters, and the daily operation time is 10 hours. The specific steps of fluorine-containing wastewater treatment are as follows:

[0050] Step 1: Collect fluorine-containing wastewater and send it to a settling tank (capacity of 8 cubic meters) to preliminarily settle the suspended solids in the wastewater and clarify the water quality.

[0051] Step 2: Send the effluent from the sedimentation tank to the pH regulator, add calcium hydroxide solution and caustic soda, the mass concentration of the added calcium hydroxide is 5g / L, add 12kg caustic soda, and stir with compressed air in the regulator, compressed air The pressure is greater than 0.2Mpa to increase the solubility of calcium hydroxide and caustic soda, and the reaction time is 30-40min. Because the fluoride ion concentra...

Embodiment 3

[0057] Fluorine-containing wastewater generated during the production process of the factory: fluoride ion concentration 13265mg / L, pH=2. The daily waste water treatment capacity is about 10 cubic meters, and the daily operation time is 10 hours. The specific steps of fluorine-containing wastewater treatment are as follows:

[0058] Step 1: Collect fluorine-containing wastewater and send it to a settling tank (capacity of 8 cubic meters) to preliminarily settle the suspended solids in the wastewater and clarify the water quality.

[0059] Step 2: Send the effluent from the sedimentation tank to the pH regulator, add calcium hydroxide solution and caustic soda, the mass concentration of calcium hydroxide added is 8g / L, add caustic soda 25kg, and stir with compressed air in the regulator, compressed air The pressure is greater than 0.2MPa, and the reaction time is 30-40 minutes. Simultaneously, calcium chloride solid is added according to the molar ratio of fluoride ion to cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com