Hemin-graphene composite material and application in detection of nitric oxide gas

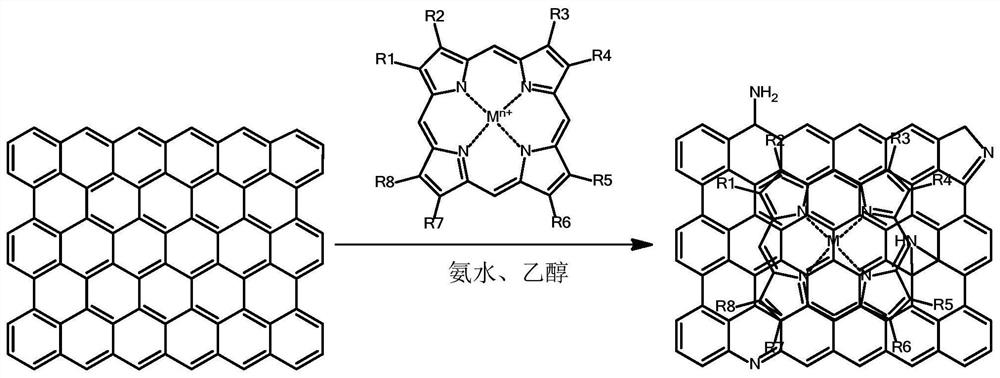

A composite material and hematin technology, which is applied in the hematoxylin-graphene composite material and its application in the detection of nitric oxide gas, can solve the problem of long response time and recovery time, poor sensitivity and selectivity, high Working temperature and other issues, to achieve the effect of high sensitivity and selectivity, easy separation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a hematin-graphene composite material, which is prepared according to the following steps:

[0047] (1) Synthesis of graphene oxide: In this embodiment, graphene oxide is synthesized by means of low temperature reaction-medium temperature reaction-high temperature reaction-centrifugation, as follows:

[0048] Low-temperature reaction: Take 23mL of 98% concentrated sulfuric acid and add it to a beaker of appropriate size, use pre-made ice cubes to cool it down to -1~1°C, then add 1g of natural graphite, stir for 50 minutes, and then slowly add 6g of potassium permanganate, stirred for 3 hours. During this period, the system temperature was kept at -1-1°C.

[0049] Medium temperature reaction: transfer the above system to a constant temperature water bath at 40°C, and stir for 45 minutes.

[0050] High temperature reaction: transfer the above system to a constant temperature water bath at 80°C. After the temperature of the system rises to 80°C, ...

Embodiment 2

[0079] Embodiment 2: Embodiment 2 provides a hematin-graphene composite material. The synthesis process is the same as that of Embodiment 1, except that the temperature for the solvothermal reaction in step (2) is 150° C.

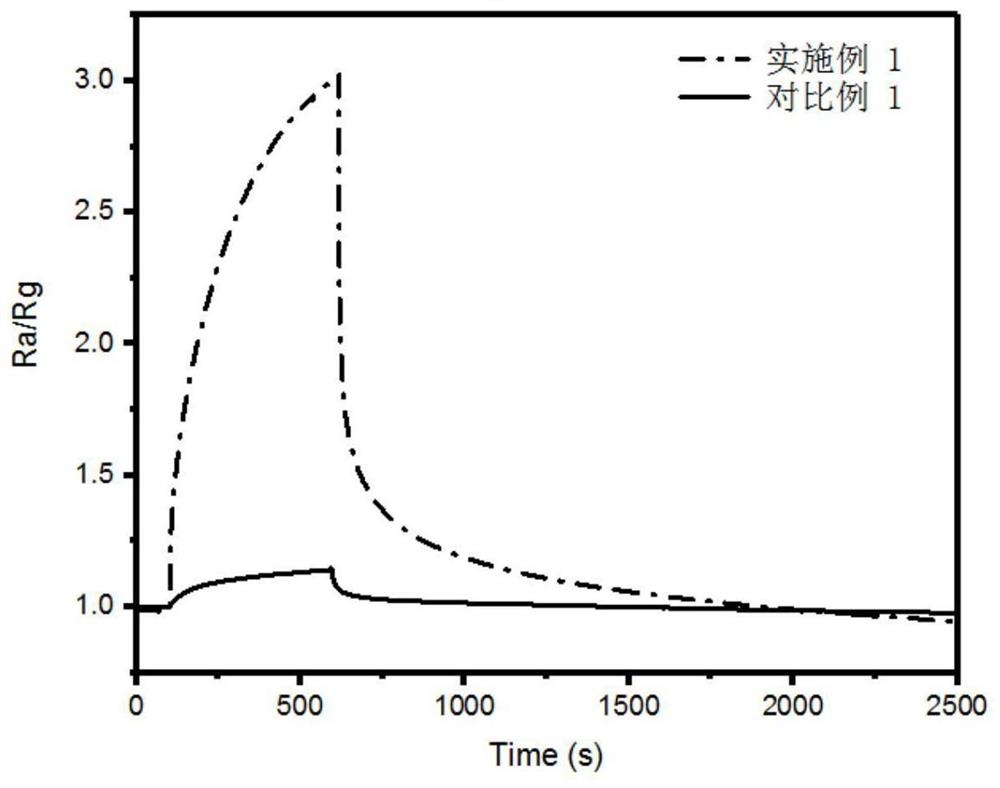

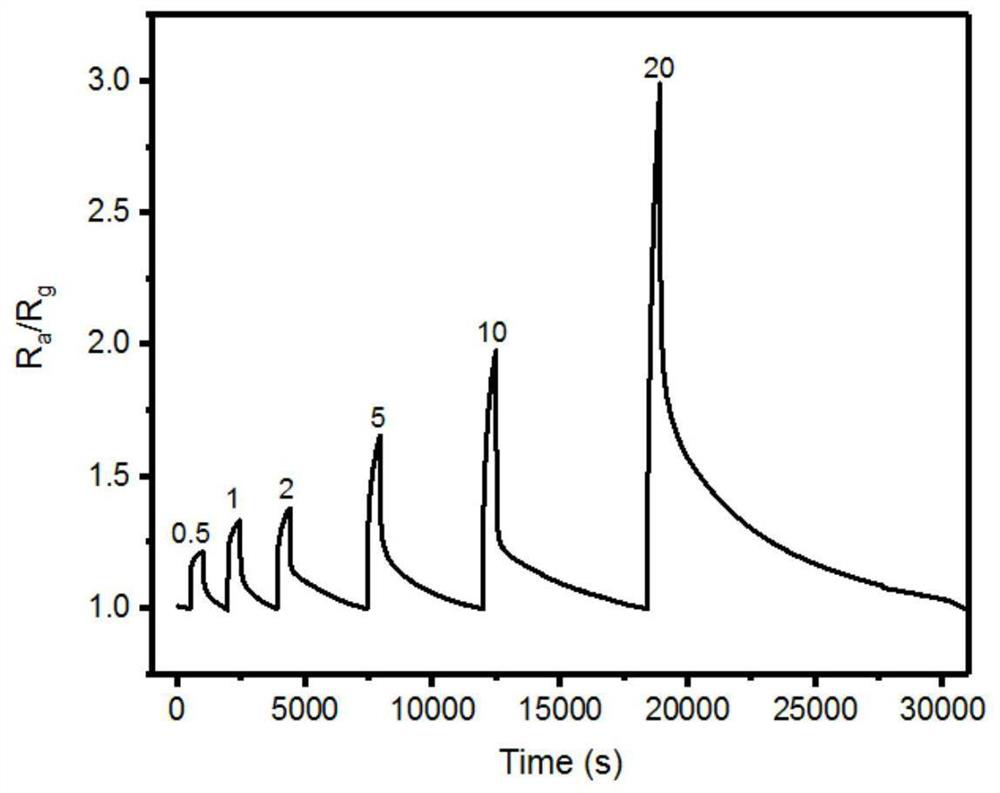

[0080] Effect comparative example 4 first prepared the gas-sensing electrode based on the composite material of comparative example 4 and the crystalline hemin-graphene composite material of embodiment 2 by the drop coating method, and the gas-sensing electrode was prepared by the following steps: respectively The anhydrous ethanol dispersion solution of the composite material prepared in Comparative Example 4 and Example 2 was shaken evenly, and 10 μL of the above solution was dropped on the interdigitated electrode of a commercial ceramic substrate, and the interdigitated electrode was heated on a hot stage at 75°C After 15 minutes, the ethanol solvent was completely evaporated.

[0081] The gas sensing performance of the above-mentioned gas-sensing elect...

Embodiment 3

[0083] Example 3 provides a dispersion of a composite material. The synthesis process is the same as that of Example 1, except that the amount of ammonia water added in step (2) is 360 μL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com