Aqueous zinc-manganese battery fiber with dual-functional protective layer and preparation method thereof

A zinc-manganese battery and protective layer technology, applied in the direction of carbon fiber, fiber treatment, fiber type, etc., can solve the problems of easy disintegration, falling off and dissolution of active materials, reduced battery cycle life, and low utilization of electrode materials, so as to speed up the electrode reaction process, improved electrochemical performance, and enhanced mechanical integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

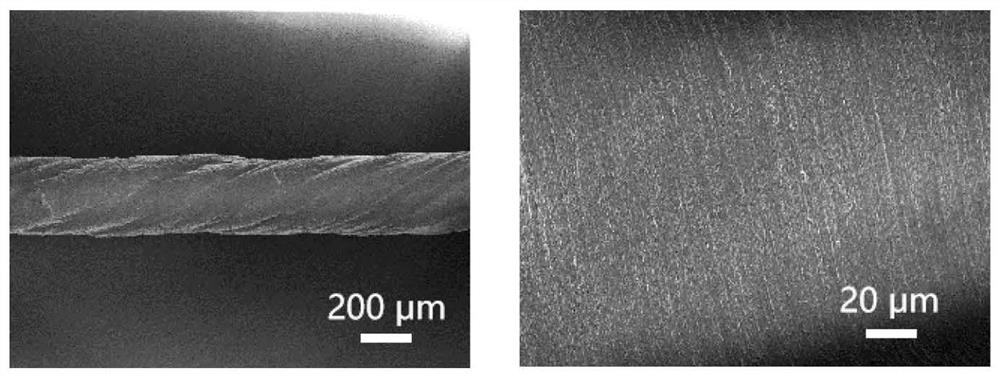

[0025] (1) Preparation of carbon nanotube fiber substrate: ethanol (> 97 wt %), argon (200 sccm) and hydrogen (2000 sccm) were used as carbon source, carrier gas and reducing gas, respectively, and thiophene (2 wt %) and di Using ferrocene (2 wt %) as a catalyst, floating carbon nanotube fibers were synthesized by floating catalytic chemical vapor deposition, and multiple strands of carbon nanotube fibers with a diameter of about 200 μm were directly twisted into flexible carbon nanotube fibers.

[0026] (2) Preparation of CM: Nanostructured manganese dioxide was electrodeposited on a flexible CNT fiber substrate to prepare a CM fiber electrode. Electrodeposition was carried out at room temperature in a solution containing 0.1 mol / L manganese acetate and 0.1 mol / L sodium sulfate, with a platinum electrode as a counter electrode and a silver / silver chloride electrode as a reference electrode. Using step voltage electrodeposition mode (1.5 V 1 s, 0.7 V 10s), through Mn 2+ + 2H...

Embodiment 2

[0033] (1) Preparation of carbon nanotube fiber substrate: ethanol (> 96 wt %), argon (200 sccm) and hydrogen (2100 sccm) were used as carbon source, carrier gas and reducing gas, respectively, and thiophene (1 wt %) and di Using ferrocene (2 wt %) as a catalyst, floating carbon nanotube fibers were synthesized by floating catalytic chemical vapor deposition, and multiple strands of carbon nanotube fibers with a diameter of about 150 μm were directly twisted into flexible carbon nanotube fibers.

[0034] (2) Preparation of CM: Electrodeposit nanostructured manganese dioxide on flexible CNT fiber substrate to prepare CM fiber electrode. Electrodeposition was carried out in a solution containing 0.2 mol / L manganese acetate and 0.2 mol / L sodium sulfate at room temperature, with a platinum electrode as the counter electrode and a silver / silver chloride electrode as the reference electrode. Electrodeposition mode by step voltage method (1.5 V 2 s, 0.7 V 12s), through Mn 2+ + 2H ...

Embodiment 3

[0041] (1) Preparation of carbon nanotube fiber substrate: ethanol (> 97 wt %), argon (150 sccm) and hydrogen (1800 sccm) were used as carbon source, carrier gas and reducing gas, respectively, and thiophene (1 wt %) and di Using ferrocene (1 wt %) as a catalyst, floating carbon nanotube fibers were synthesized by floating catalytic chemical vapor deposition, and multiple strands of carbon nanotube fibers with a diameter of about 100 μm were directly twisted into flexible carbon nanotube fibers.

[0042] (2) Preparation of CM: Electrodeposit nanostructured manganese dioxide on flexible CNT fiber substrate to prepare CM fiber electrode. Electrodeposition was carried out at room temperature in a solution containing 0.1 mol / L manganese acetate and 0.2 mol / L sodium sulfate, with a platinum electrode as the counter electrode and a silver / silver chloride electrode as the reference electrode. Electrodeposition mode by step voltage method (1.5 V 1 s, 0.7 V 15 s), through Mn 2+ + 2H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com