Quartz resonator based on piezoelectric film transduction and electronic equipment

A technology of quartz resonators and piezoelectric thin films, applied in the direction of electrical components, impedance networks, etc., can solve problems such as the difference in frequency and temperature coefficient of piezoelectric thin film layers, difficulties in preparing quartz resonators, and low electromechanical coupling coefficients, and achieve device manufacturing processes Easy, high frequency stability, high Q effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

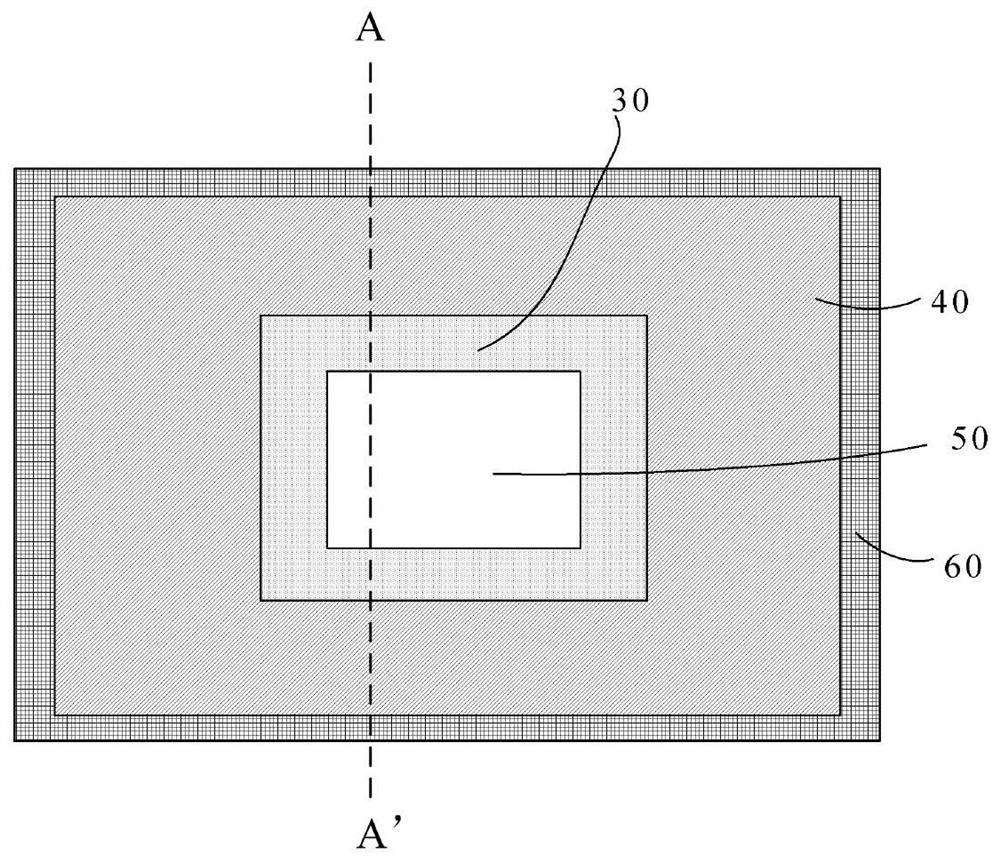

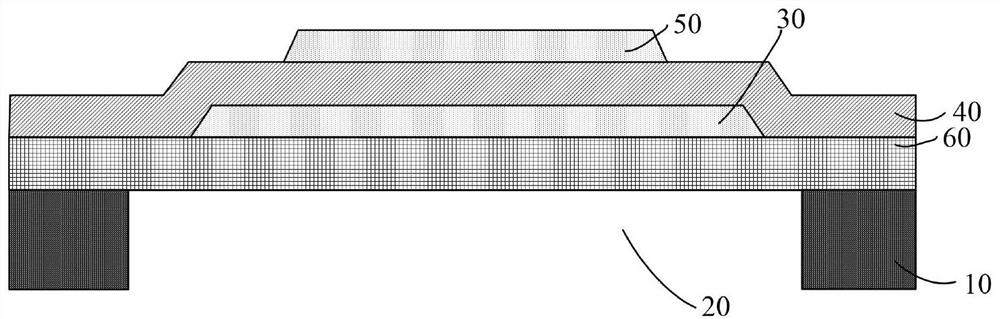

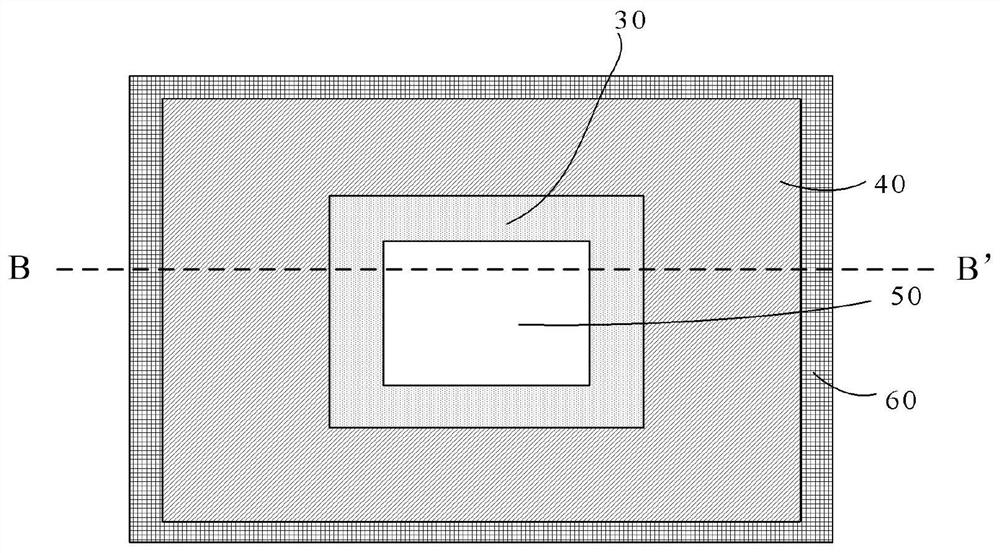

[0022] The details of each part marked in the figure in this article are as follows:

[0023] 10: Substrate, the material can be single crystal silicon, gallium arsenide, sapphire, quartz or lithium niobate, etc.

[0024] 20: Acoustic mirror, specifically an air cavity, a Bragg reflection layer or other equivalent acoustic reflection structures.

[0025] 30 / 50: The first electrode / the second electrode, the material can be molybdenum, platinum, gold, aluminum, copper, silver and other commonly used thin film electrode materials or the composite or alloy of the above metals.

[0026] 40: Piezoelectric film transduction layer, the material can be selected from non-quartz piezoelectric film materials such as aluminum nitride, doped aluminum nitride, zinc oxide, lithium niobate, lithium tantalate or lead zirconate titanate, and the material is required to be electromechanically coupled The coefficient is greater than the electromechanical coupling coefficient of quartz.

[0027] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com