Chicken manure derived charcoal-loaded nanometer zero-valent iron composite material as well as preparation method and application thereof

A technology of nano-zero-valent iron and composite materials, which is applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of unprepared chicken manure-derived biochar loaded with nano-zero-valent iron, and achieve overcoming agglomeration Effects on sexual problems, environment friendly, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing a chicken manure-derived biochar-loaded nano-zero-valent iron composite material, comprising the following steps:

[0056] a) Under the protection of inert gas, conduct high-temperature pyrolysis of chicken manure in a tube furnace, remove impurities with acid solution after cooling, and dry after several times of cleaning to obtain chicken manure-derived biochar particles;

[0057] b) Mixing the chicken manure-derived biochar and ferrous salt solution in water evenly to obtain a chicken manure-derived biochar-ferrous salt mixed solution;

[0058] c) Under the protection of an inert gas, the mixed solution is subjected to a redox reaction with a reducing agent to obtain a chicken manure-derived biochar-loaded nano-zero-valent iron suspension;

[0059] d) The suspension is subjected to solid-liquid separation, and the black solid particles are washed, and dried to obtain nano zero-valent iron particles loaded wit...

Embodiment 1

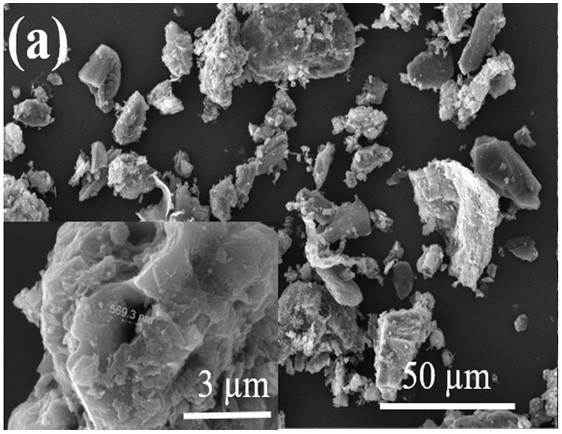

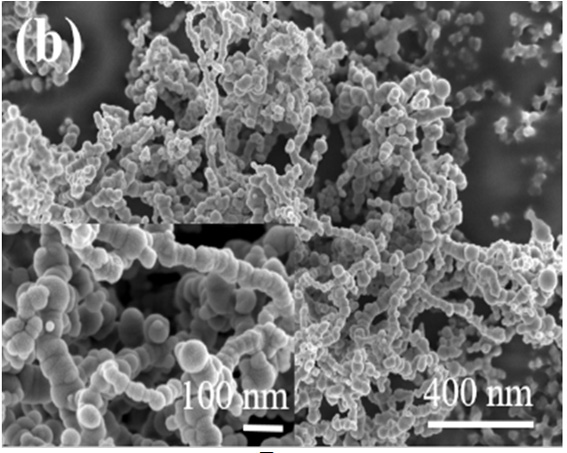

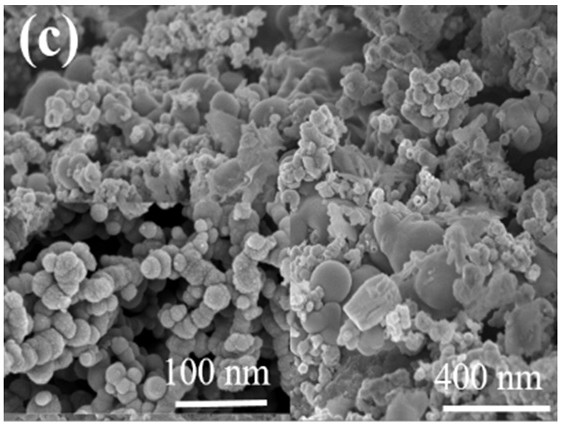

[0083] A chicken manure-derived biochar-loaded nano-zero-valent iron composite material uses chicken-manure-derived biochar (CMBC) as a carrier, and supports nano-zero-valent iron particles on the surface and internal pores of CMBC. The preparation process includes the following steps:

[0084] (1) Preparation of chicken manure-derived biochar (CMBC)

[0085] After the fermented chicken manure was naturally dried, it was ground and sieved (100 mesh), and a certain amount of sieved chicken manure was weighed and placed in a tube furnace. Nitrogen was introduced for 30 minutes, and the temperature was raised to 600 °C at a rate of 10 °C / min. ℃ and kept for 2h (nitrogen protection throughout the pyrolysis process) to obtain carbonized black solid particles, after cooling to room temperature, use 0.5mol / L HCl solution to soak for 24h (the ratio of solid particles to HCl solution is 1g:100ml), and finally use The solid particles were washed with deionized water until the pH of the ...

Embodiment 2

[0103] Refer to Example 1 for the specific steps. The difference is that the dosage of chicken manure-derived biochar in the step (2) preparation of chicken manure-derived biochar-ferrous salt mixed solution is 0.1g, 0.25g, 1g and 2.5g respectively. g, that is, the mass ratio of nZVI to CMBC in the mixed solution is 1:0.2, 1:0.5, 1:2 and 1:5, respectively. The obtained chicken manure-derived biochar-loaded nano-ZVI particles were denoted as nZVI@0.2CMBC, nZVI@0.5CMBC, nZVI@2CMBC and nZVI@5CMBC, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com