Bi (Fe, Zn) O3/NiO all-oxide thin film heterojunction used for high-speed photoelectric detection

An oxide thin film and heterojunction technology, applied in photovoltaic power generation, sustainable manufacturing/processing, circuits, etc., can solve the problem of high photogenerated electron-hole recombination rate, photoelectric response speed needs to be improved, unfavorable visible light absorption and conversion, etc. problems, achieve high-speed photoelectric response characteristics, improve carrier transport efficiency, and achieve low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

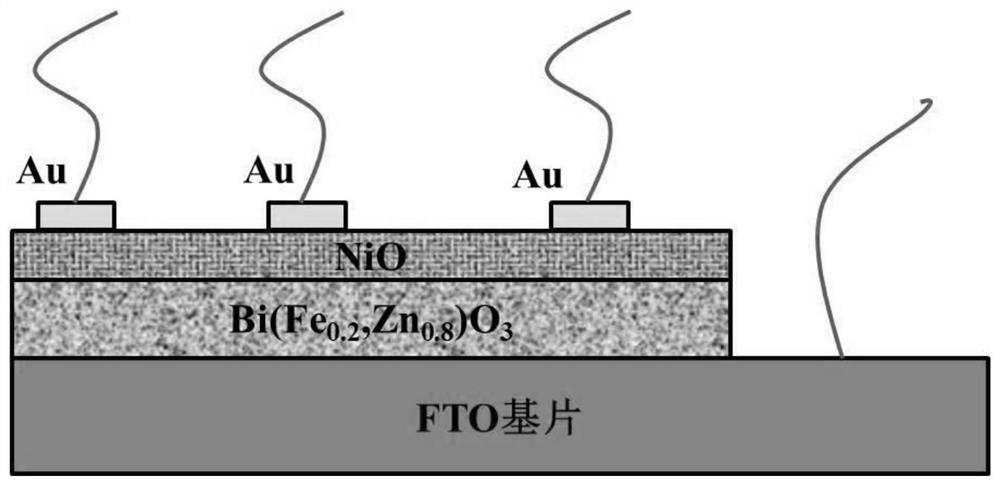

[0044] Such as figure 1 As shown, a Bi(Fe 0.2 ,Zn 0.8 )O 3 / NiO thin film heterojunction, including Bi(Fe 0.2 ,Zn 0.8 )O 3 and NiO bilayer films.

[0045] The specific process of preparing the heterojunction in this example is as follows:

[0046] Weigh iron nitrate, bismuth nitrate, and zinc nitrate powders according to the molar ratio, put them in a beaker, add 6ml of ethylene glycol methyl ether, and stir evenly at room temperature for 30 minutes. The temperature of the solution was raised to 60°C, 3ml of acetic acid and 3ml of acetic anhydride were added successively and continued to heat and stir until a transparent reddish-brown color appeared, then the heating was stopped, the stirring was continued for 2 hours, and then aged for 6 hours to obtain Bi(Fe 0.2 ,Zn 0.8 )O 3 Precursor solution liquid.

[0047] Weigh an appropriate amount of nickel acetate powder and place it in a beaker, add 20ml of ethylene glycol methyl ether, and stir evenly at room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com