Alfalfa antioxidant glycoprotein as well as preparation method and application thereof

A technology of alfalfa leaf protein and oxidized sugar, which is applied in the field of protein modification, can solve the problems of poor functional properties such as anti-oxidation and limited application, and achieve the effect of improving anti-oxidation, improving clearance rate and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Extraction of alfalfa leaf protein

[0051] According to Haibin L, Wei Z, Yuantao C, et al. Technology optimization of Medicago sativa leaf protein separation with foam fractionation [J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(9): 271-276) A method for extracting alfalfa leaf protein, separating, concentrating, and drying.

[0052] 2. Moist heat Maillard reaction

[0053] According to the substrate ratio of 1:1 (m alfalfa leaf protein: m sugar), ribose, xylose, glucose, galactose, maltose, lactose, xanthan gum, linseed gum, etc. were selected respectively at a reaction pH of 9.0 , the time is 1h, and the temperature is 100°C, and the wet heat Maillard reaction is carried out with alfalfa leaf protein, and the total reducing ability of the reaction product is determined.

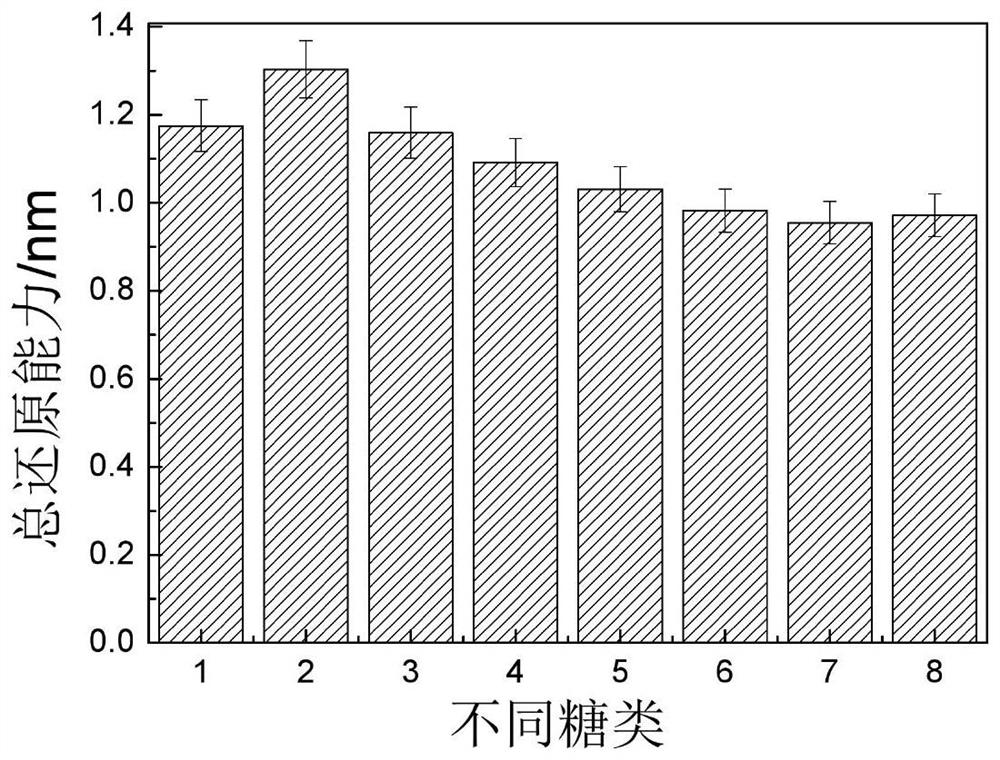

[0054] The result is as figure 1 As shown, the antioxidant product of the xylose-alfalfa leaf protein system has the most significant antioxidant activity, so i...

Embodiment 2

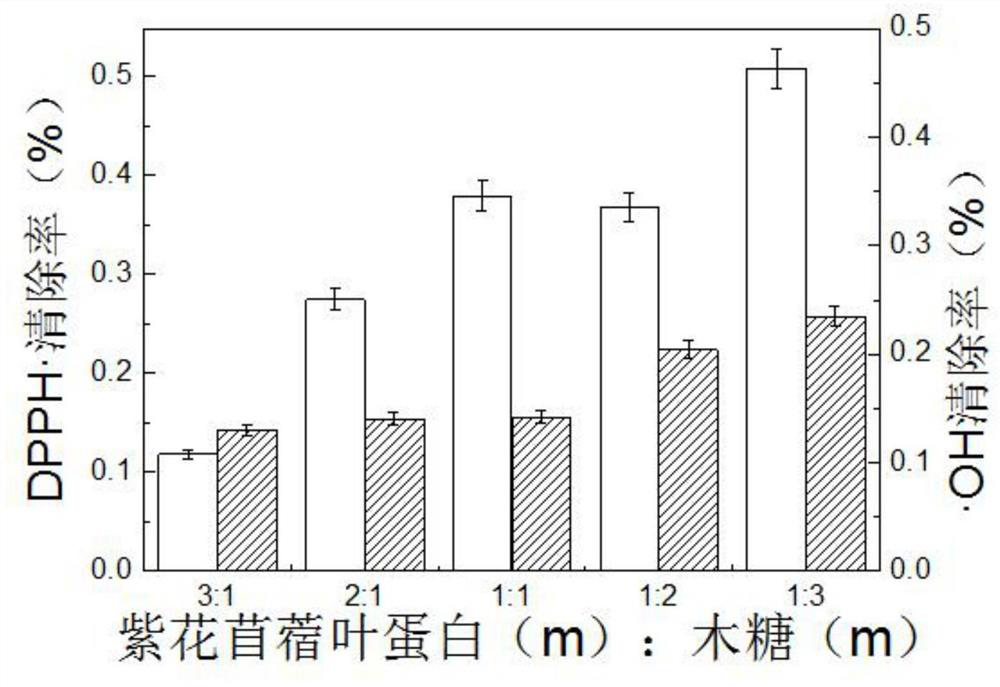

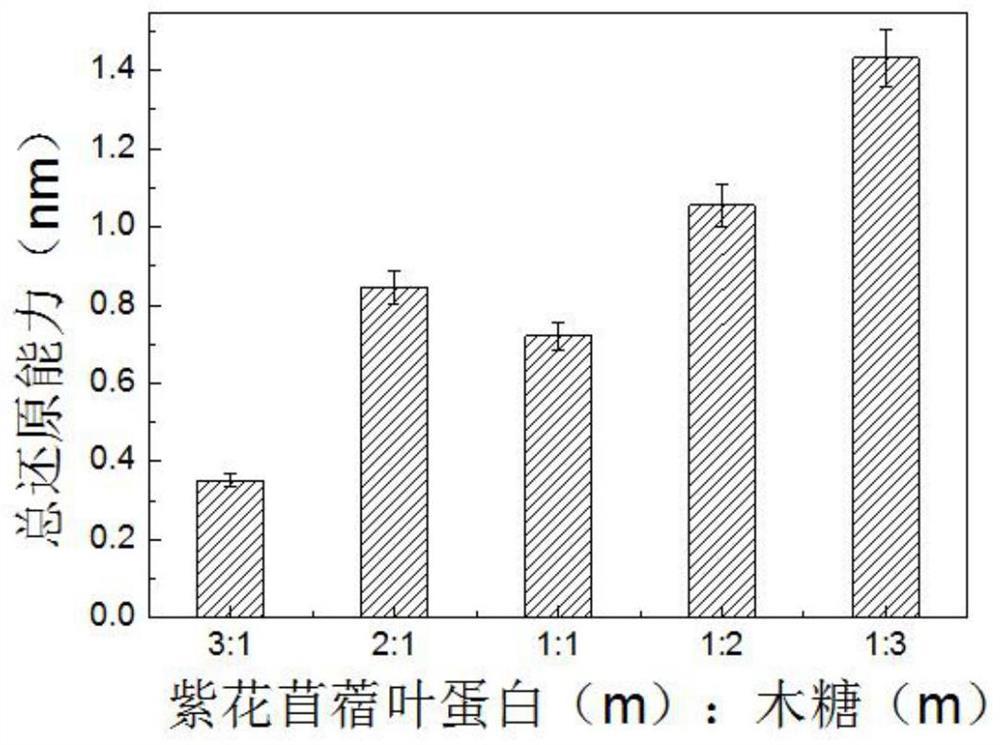

[0056] The effect of different proportions of raw materials on the oxidation resistance of the product

[0057] Accurately weigh 0.1g, 0.2g, 0.3g according to the substrate (m alfalfa leaf protein: m xylose) ratio of 1:1, 2:1, 3:1, 1:2, 1:3 , 0.1g, 0.1g of alfalfa leaf protein in five Erlenmeyer flasks with the same specifications and add xylose with a quality of 0.1g, 0.1g, 0.1g, 0.2g, 0.3g respectively, and add 100mL distilled water, Stir and sonicate to dissolve it evenly. The pH values of the above five solutions were respectively adjusted to 9.0 with 0.1 mol / L HCl and NaOH solutions. Put the five solutions with adjusted pH value into the autoclave to carry out the Maillard reaction, set the initial reaction temperature to 100°C, and the reaction time to 1h, take it out immediately after the reaction is completed, and interrupt the reaction with circulating cold water, When the solution in the Erlenmeyer flask was cooled to room temperature, the products in different p...

Embodiment 3

[0062] The effect of different pH values on the oxidation resistance of the product

[0063] Accurately weigh 0.1g of alfalfa leaf protein into five Erlenmeyer flasks with the same specification, add 0.3g of xylose into it, add 100mL of distilled water, stir and ultrasonically dissolve it evenly. The pH values of the five solutions were adjusted to 7.0, 8.0, 9.0, 10.0, and 11.0 with 0.1 mol / L HCl and NaOH solutions. Put the five solutions with adjusted pH value into the autoclave to carry out the Maillard reaction, set the initial reaction temperature to 100°C, and the reaction time to 1h, take it out immediately after the reaction is completed, and interrupt the reaction with circulating cold water, When the solution in the Erlenmeyer flask was cooled to room temperature, the products at different pH values were centrifuged at 8000r / min for 5 minutes, and the remaining supernatant was suction-filtered to remove unreacted impurities to obtain liquid antioxidant products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com