Catenary steel wrist arm positioning device and processing method coated with dirt-repellent composite coating

A technology of positioning device and composite coating, which is applied in the direction of coating, conductive coating, anti-corrosion coating, etc., can solve the problems that there is no coating technology and products, and affect the conductive performance of catenary, so as to improve the service life and operation safety and reliability, Excellent salt spray corrosion resistance and adhesion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

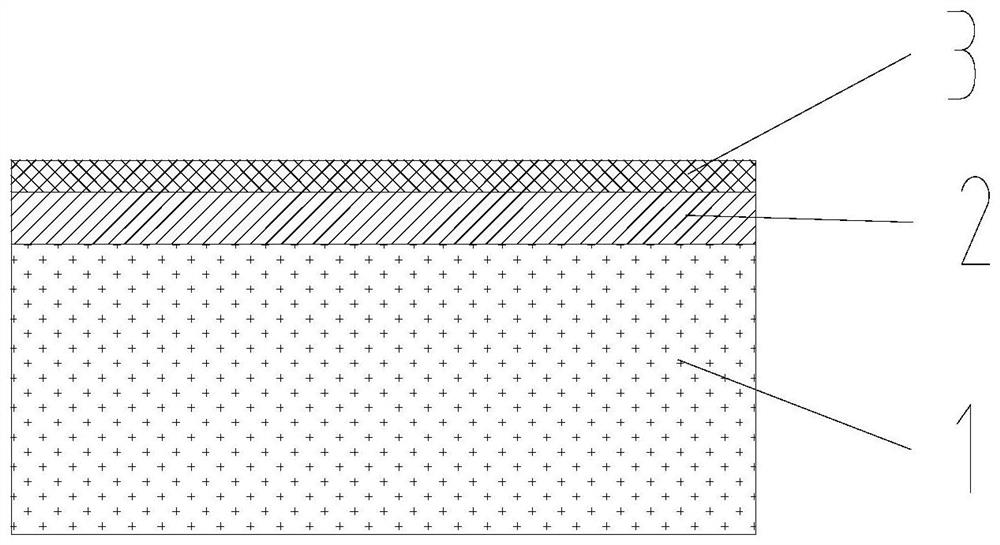

[0072] According to the mass meters, 10 parts of film formable resin (silicone modified bisphenol A epoxy resin SM-60), 55 silicone monomers (methyltriethoxysilane), crosslinking agent ( Ethyl orthosilicate) 0.5 parts, 5 parts of interface adhesive (aminopropyl triethoxysilane), 0.1 parts of catalyst (dibutylminikinikin), 30 copies of conductive filler (1 μm-shaped aluminum powder), Corrosion inhibition passivator (sodium molybdate), oriented from 0.2 parts, anti-sediment (organic bentonite), solvent (6 parts of ethanol, 4 parts of propylene glycol) 10 Part, defoamer (DEFOM 8700), 5 parts of color fat (iron oxide), mixed stirring is uniform, milling in the sand mill to about 25 μm, that is, the contact network assembly is obtained. Anti-corrosion-resistant electrical hydroxation coating.

Embodiment 2

[0074] According to the mass meters, 20 parts of film forming resin (silicone modified bisphenol A epoxy resin SM-60), 40 parts of silicone monomer (40 parts of methyltriethoxysilane, methyl trichlorosilane) 25 parts: 65, crosslinking agents (methyl silicate), 10 parts of interface adhesive (aminopropyl triethoxysilane), 0.3 parts of catalyst (organic bismuth catalyst), conductive filler (1 μm 60 parts of aluminum powder), 3 parts of corrosion inhibitor (cerium nitrate), 0.4 parts of directional dispensing agent (polyvinylpyrrolidone), 6 parts of anti-sediment (organic bentonite), solvent (12 parts of ethanol, propylene glycol methyl) 8 copies of 20 parts, 4,000 defoaming agents (DEFOM 8700), 20 parts of color fat (iron oxide), mixed stirring uniform, milled in the sand mill to about 25 μm, that is, Contact mesh components use anti-corrosion-resistant electrical hydroxion coating.

Embodiment 3

[0076] According to the mass meters, 15 parts of film forming resin (silicone modified bisphenol A epoxy resin SM-60), 40 parts of silicone monomer (140 parts of methyltriethoxysilane, dimethyl chloride) 15 parts of silane 55 parts, crosslinking agent (ethyl orthosilicate), 8 parts of interface adhesive (aminopropyl triethoxysilane), 0.2 copies of catalyst (dibutylminikinikin), conductive 50 parts of the filler (1 μm sheet-shaped aluminum powder), two corrosion inhibition passivator (cerium nitrate), 4 parts of the orientation dispenser (polyvinylpyrrolidone), 4 parts, solvent (8 parts of ethanol) , 7 parts of propylene glycol methyl ether), 0.6 parts of the defoaming agent (DEFOM 8700), 15 parts of the color fat (iron oxide), mixed stirring is uniform, milling in the sand mill is about 25 μm, ie The contact network assembly is obtained with anti-corrosion-resistant electrical hydroximosis coating.

[0077] In summary, the plan of the present invention has a significant advantage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com