Graphite-phase carbon nitride-modified silicon oxide porous microsphere-supported heterogeneous rhodium catalyst and preparation method and application thereof

A graphite-phase carbon nitride and heterogeneous catalyst technology, which is applied in the preparation of carboxylic acid by carbon monoxide reaction, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of difficult preparation and collapse of catalyst structure Or reconstruction, recycling and reuse problems, etc., to achieve the effect of simple use method, simple reaction device, and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

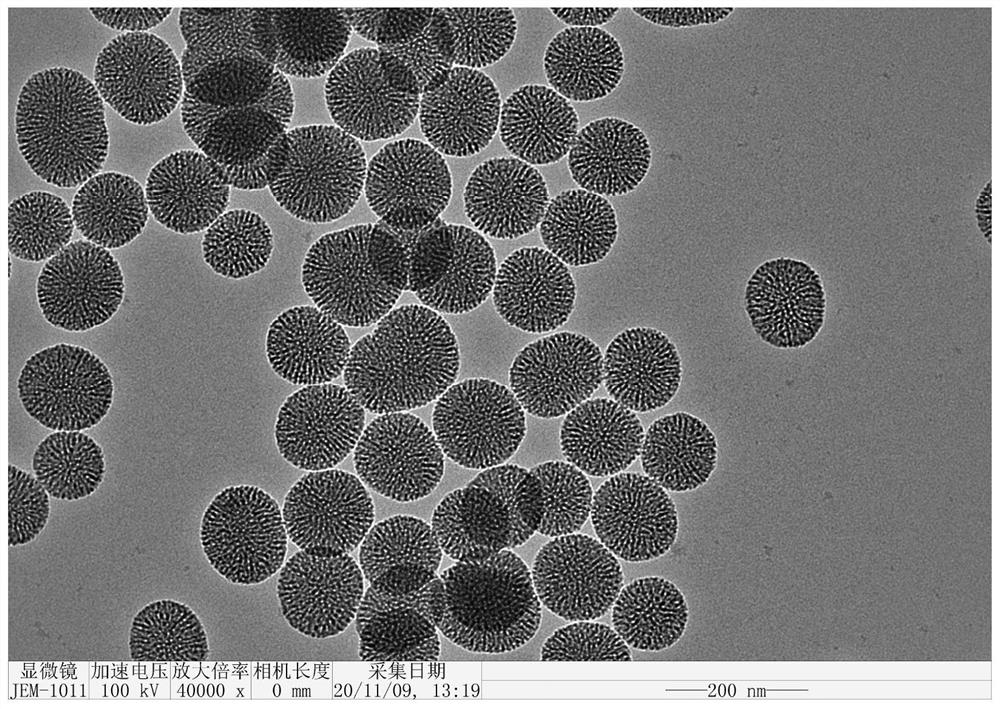

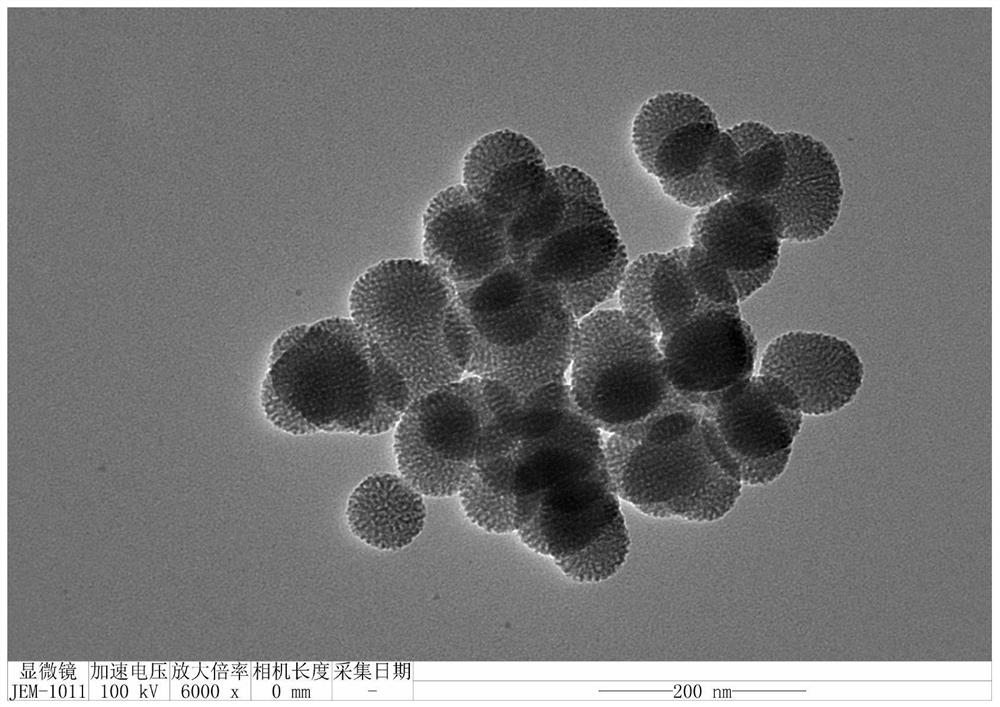

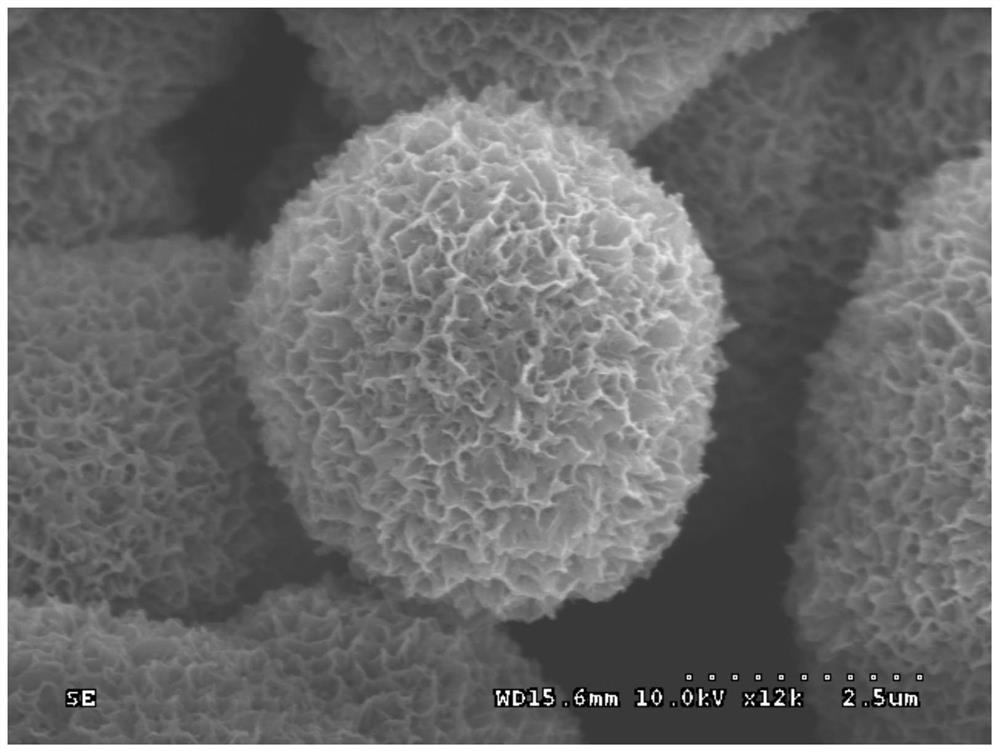

[0033] As an improvement, the preparation method of the graphite-phase carbon nitride-modified silicon oxide porous microspheres comprises the following steps:

[0034] Step 1: Weigh the precursor compound containing carbon and nitrogen elements together with water or alcohol solvent to form a 30%-50% precursor solution, dry the silicon oxide porous microspheres at high temperature to remove water, and quickly add them to In the precursor solution, the volume of silicon oxide porous microspheres is about 90% of the volume of the precursor solution; the alcohol solvent is methanol, ethanol or propanol;

[0035] Step 2, heat up the silicon oxide porous microspheres after absorbing the precursor solution to 80°C at a heating rate of 1°C / min, keep it warm for 3-5 hours, continue to heat up to 120°C and keep it for 2 hours, and dry it. According to the concentration of the precursor solution, sequentially Repeat step 1 and step 2, cycle 1-2 times;

[0036] In step 3, the temperatu...

Embodiment 1

[0047] Get 5 grams of graphite-phase carbon nitride-modified silica porous microsphere carriers, 20 mg of dichlorotetracarbonyl dirhodium (belonging to carbonyl rhodium), dissolve them in an appropriate amount of ethanol solution, stir and mix, put into a quartz tube after drying , Burning at 550°C for 2 hours under the protection of argon to become a catalyst containing 0.21% rhodium.

[0048] 5 grams of catalysts with a rhodium content of 0.21% are put into a column reactor, and carbon monoxide is introduced to remove the air in the column, then the temperature is raised to 180° C., and the partial pressure of carbon monoxide is maintained at 1 MPa. A mixture of methanol and methyl iodide (according to the molar ratio of 10:1) was injected into the reaction column at a rate of 1 ml / min with a pressure pump. Collect the cooled reaction product from the outlet of the reaction column. The conversion rate of methanol in the product was 83%, calculated based on converted methano...

Embodiment 2

[0053] Get 5 grams of silica porous microsphere carrier modified by carbon nitride of graphite phase, 48 mg of dirhodium dichlorotetracarbonyl, dissolve in ethanol solution, stir and mix, put into quartz tube after drying, under argon protection Burn at 300°C for 2 hours to become a catalyst containing 0.5% rhodium.

[0054] The rhodium content is that 0.5% catalyst 5 grams are put into the tube column reactor, remove the air in the tube column with carbon monoxide, then be warming up to 185 ℃, keep the carbon monoxide partial pressure as 1MPa, methyl alcohol and methyl iodide mixed solution (according to The molar ratio is 10:1) using a pressure pump to inject into the reactor at a rate of 1 ml / min. The cooled product was collected at the reactor outlet. The conversion rate of methanol in the product is 87%, calculated based on converted methanol, the yield of acetic acid is 74%, and the yield of methyl acetate is 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com