Environment-friendly water-based release agent and preparation method thereof

A water-based release and environmental protection technology, applied in coatings, fireproof coatings, wax coatings, etc., can solve problems such as hazards, difficulty in secondary processing, unfavorable mold cleaning and secondary processing, etc., and achieve broad application prospects and good mutual Effect, the effect of not easy to break the emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

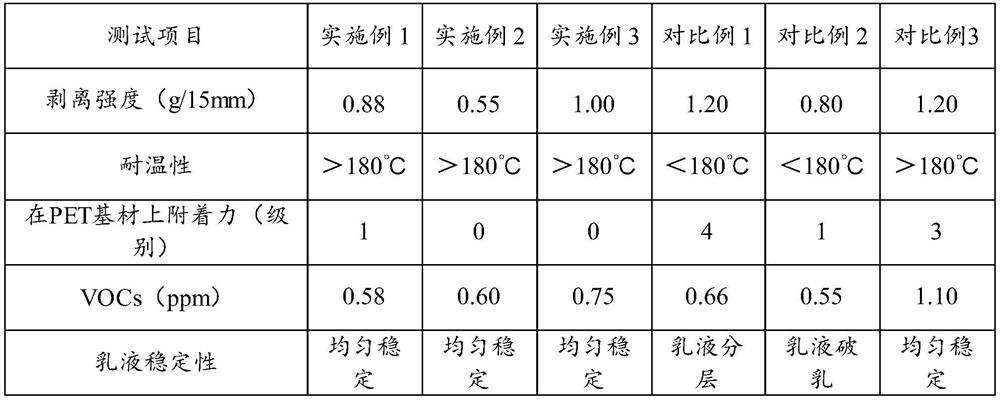

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of the environment-friendly water-based release agent described in the above-mentioned technical scheme, comprising the following steps:

[0050] a) uniformly mixing fatty alcohol polyoxyethylene ether, oleylamine polyoxyethylene ether, fatty alcohol polyoxyethylene ether phosphate and polyethylene glycol monostearate to obtain a composite emulsifier;

[0051] b) Under stirring conditions, mix natural wax and water, after heating up to the reaction temperature, add the above-mentioned composite emulsifier and polyethyleneimine dropwise respectively; after the dropwise addition is completed, react; after cooling, add defoamer and The preservatives are evenly mixed to obtain an environmentally friendly water-based release agent.

[0052] In the present invention, firstly, fatty alcohol polyoxyethylene ether, oleylamine polyoxyethylene ether, fatty alcohol polyoxyethylene ether phosphate and polyethylene glycol monos...

Embodiment 1

[0064] (1) Raw material weight ratio:

[0065] Natural wax 15.5wt%;

[0066] Polyethyleneimine 0.2wt%;

[0067] Fatty alcohol polyoxyethylene ether 0.5wt%;

[0068] Oleylamine polyoxyethylene ether 1.0wt%;

[0069] Fatty alcohol polyoxyethylene ether phosphate 0.4wt%;

[0070] Polyethylene glycol monostearate 1.5wt%;

[0071] Defoamer 0.2wt%;

[0072] Preservative 0.1wt%;

[0073] Water 80.6wt%.

[0074] (2) The preparation method steps are as follows:

[0075] ① Mix fatty alcohol polyoxyethylene ether, oleylamine polyoxyethylene ether, fatty alcohol polyoxyethylene ether phosphate and polyethylene glycol monostearate evenly to obtain a compound emulsifier;

[0076] ②Add natural wax particles and water into the high-temperature and high-pressure reactor, start stirring, and keep the rotation speed at 130r / min-140r / min. After the temperature rises to 85°C-95°C, slowly add the above-mentioned compound emulsifier dropwise, and control the dropping time as 1h, drop polyet...

Embodiment 2

[0078] (1) Raw material weight ratio:

[0079] Natural wax 16wt%;

[0080] Polyethyleneimine 1.0wt%;

[0081] Fatty alcohol polyoxyethylene ether 0.75wt%;

[0082] Oleylamine polyoxyethylene ether 1.2wt%;

[0083] Fatty alcohol polyoxyethylene ether phosphate 0.5wt%;

[0084] Polyethylene glycol monostearate 1.7wt%;

[0085] Defoamer 0.25wt%;

[0086] Preservative 0.2wt%;

[0087] Water 78.4 wt%.

[0088] (2) The preparation method steps are as follows:

[0089] ① Mix fatty alcohol polyoxyethylene ether, oleylamine polyoxyethylene ether, fatty alcohol polyoxyethylene ether phosphate and polyethylene glycol monostearate evenly to obtain a compound emulsifier;

[0090] ②Add natural wax particles and water into the high-temperature and high-pressure reactor, start stirring, and keep the rotation speed at 130r / min-140r / min. After the temperature rises to 85°C-95°C, slowly add the above-mentioned compound emulsifier dropwise, and control the dropping time as 1h, drop polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com