Method for preparing low-temperature titanium chloride slag from low-grade titanium concentrate

A low-grade titanium and titanium chloride technology, applied in the fields of environmental protection, energy saving, and metallurgy, can solve problems such as secondary pollution, and the proportion of carbon, nitrogen, and oxygen cannot be accurately controlled, so as to save energy consumption, facilitate magnetic separation, and broaden the market The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

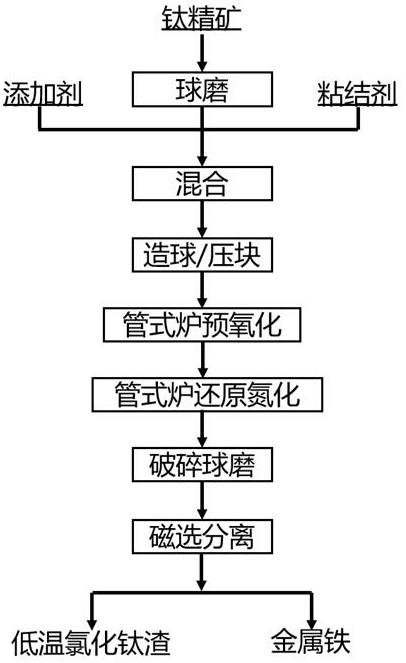

Method used

Image

Examples

Embodiment 1

[0032] In the existing low-quality titanium essence of phening, the main chemical composition is shown in Table 1.

[0033] Table 1 Main chemical composition of titanium concentrate

[0034] TIO 2

S Feo FE 2 O 3

SiO 2

Cao MGO 47.53 0.18 36.33 5.33 2.53 0.765 3.58

[0035] This embodiment uses the method of the present invention, and the specific steps are as follows:

[0036] Work with 100 parts by weight of titanium precision to 0.074 mm or less, with 10 parts by weight of NASO 4 Uniformly mixed with 0.2 parts by weight of methylcellulose binder, pressed with a mold having a diameter of 10 mm to prepare a ball.

[0037] Put the ball in a high temperature tubular reaction furnace, the pre-oxidation temperature is 1000 ° C, heat insulation for 1 h, and then introduced into the air in the cooker, then access NH at 1000 ° C. 3 -H 2 Restore the nitridation process, in NH 3 -H 2 Insulation for 3h. Among them, the volume fraction of ammonia gas and ...

Embodiment 2

[0040] In this example, the method of the present invention is prepared by the preparation of low-temperature chloride slag for the preparation of the low-quality titanium precision as described in Example 1. The specific steps are as follows:

[0041] Work with 100 parts by weight of titanium precision to 0.074 mm or less, with 10 parts by weight of NASO 4 Uniform mixed with 0.2 parts by weight of methylcellulose binder, pressed with a mold having a diameter of 5 mm to prepare a ball.

[0042] The ball is pre-oxidized in a high temperature tubular reaction furnace, the pre-oxidation temperature is 1000 ° C, holding the temperature of 2 h, then passing into argon to remove air in the cooker, then access NH at 1100 ° C. 3 -H 2 Restore the nitridation process, in NH 3 -H 2 Insulation for 8 h. Among them, the volume fraction of ammonia gas and hydrogen is 50%.

[0043] The high temperature tubular reactor is cooled to room temperature, and the reaction after the reaction is removed, ...

Embodiment 3

[0045] In this example, the method of the present invention is prepared by the preparation of low-temperature chloride slag for the preparation of the low-quality titanium precision as described in Example 1. The specific steps are as follows:

[0046] Work with 100 parts by weight of titanium precision to 0.074 mm or less, with 10 parts by weight of NASO 4 Uniformly mixed with 0.2 parts by weight of methylcellulose binder, pressed with a mold having a diameter of 10 mm to prepare a ball.

[0047] Place the ball in a high temperature tubular reaction furnace, which is then passed into argon to remove the air in the cooker, then pass at 900 ° C to NH. 3 -H 2 Restore the nitridation process, in NH 3 -H 2 Insulation 1H. Among them, the volume fraction of ammonia gas and hydrogen is 50%.

[0048] The high temperature tubular reactor is cooled to room temperature, and the reaction after the reaction is removed, then the ball mill is broken to 0.074 mm or less, and the magnetic separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com