High-quality and high-efficiency production method of in-situ polymerization flame-retardant chinlon 66 fully-drawn yarn

A technology of in-situ polymerization and fully drawn filaments, which is applied in the manufacture of fire-resistant and flame-retardant filaments, the melting of filament raw materials, and single-component polyamide artificial filaments. It can solve the problems of poor durability of flame-retardant properties and mechanical properties of materials. impact, fabric comfort and other issues, to achieve long-lasting flame retardant effect, less impact on mechanical properties, and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1, preparation of in-situ polymerization flame-retardant nylon 66 fully drawn yarn

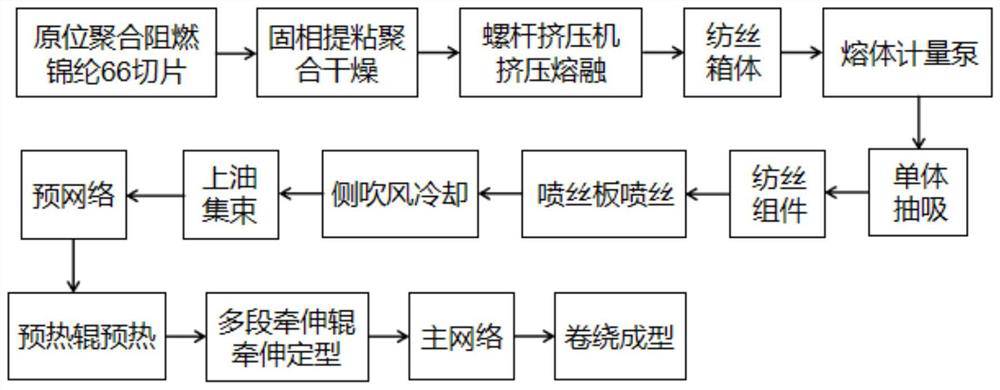

[0048] The preparation process is as figure 1 shown.

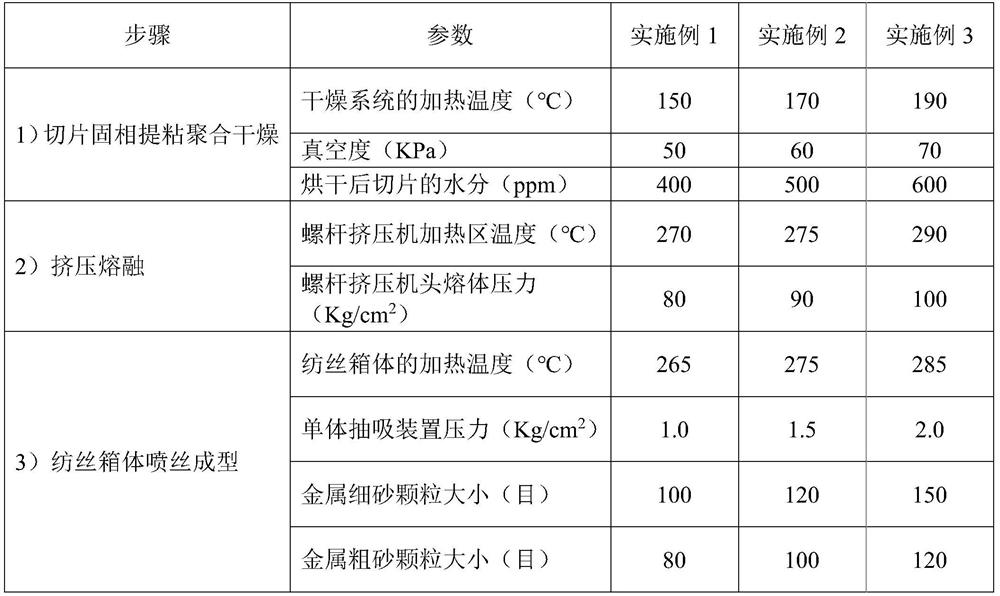

[0049] 1) The in-situ polymerized flame-retardant nylon 66 slices with a phosphorus content of 3500ppm were dried and viscosified by using a solid-phase viscosifying device. The specific reaction conditions were: the drying temperature was 150°C, the vacuum degree in the device was 50KPa, and the time was After 36 hours, the water content of the slices was 400ppm after drying, and the relative viscosity of the slices was 2.6. An independent monomer extraction system is installed in the solid-phase viscosity extraction device to remove the small molecular monomers produced by the reaction, and a palladium-based catalyst device is introduced to continuously release the catalyst Pd(OAc) 2 , to further speed up the removal rate of small molecular monomers, thereby improving the slice purity and preparation efficiency.

[0050...

Embodiment 2

[0061] Example 2, preparation of in-situ polymerization flame-retardant nylon 66 fully drawn yarn

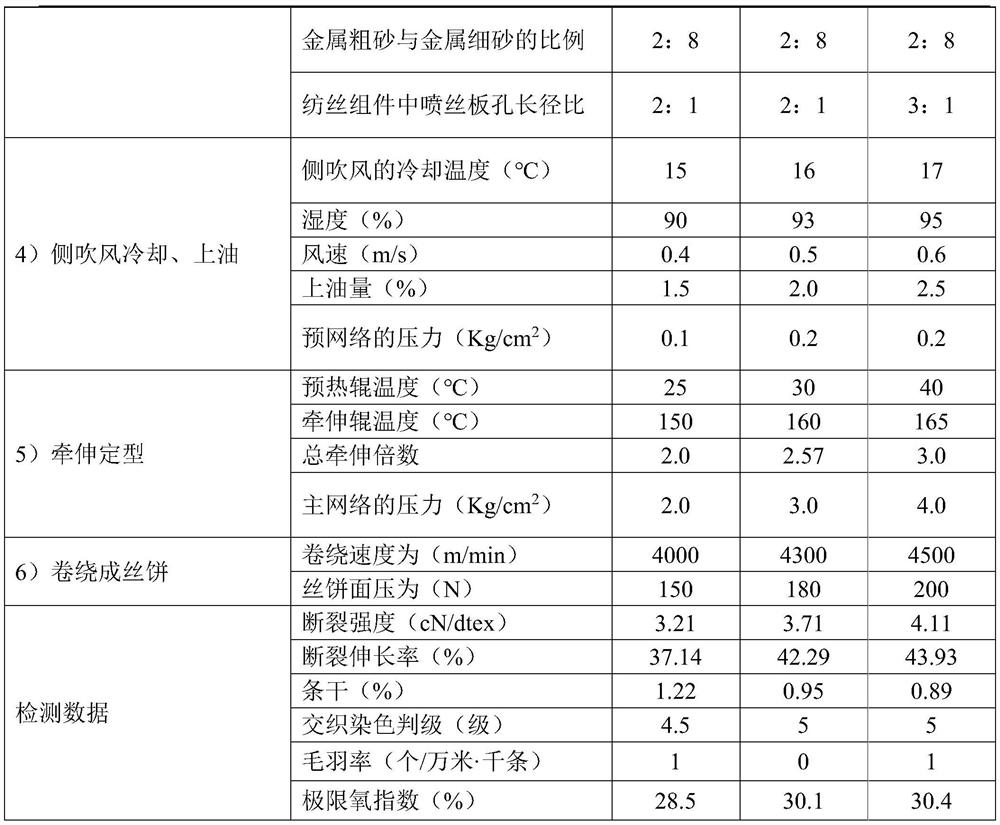

[0062] According to the steps in Example 1, the specific conditions are shown in Table 1.

[0063] Among them, the phosphorus content of the in-situ polymerization flame-retardant nylon 66 chips is 5500ppm.

[0064] The indicators of the flame-retardant nylon 66 fully drawn yarn prepared in this example are shown in Table 1.

Embodiment 3

[0065] Example 3, preparation of in-situ polymerization flame-retardant nylon 66 fully drawn yarn

[0066] According to the steps in Example 1, the specific conditions are shown in Table 1.

[0067] Among them, the phosphorus content of the in-situ polymerization flame-retardant nylon 66 chips is 4500ppm.

[0068] The indicators of the flame-retardant nylon 66 fully drawn yarn prepared in this example are shown in Table 1.

[0069] The index of the flame-retardant nylon 66 full-drawn silk prepared by the embodiment 1-3 of table 1

[0070]

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com