Preparation method of MXene/NiCoP/NF composite material

A composite material and solution technology, which is applied in the field of preparation of MXene/NiCoP/NF composite materials, can solve problems such as environmental impact and destruction of ecosystems, and achieve the effect of improving performance and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

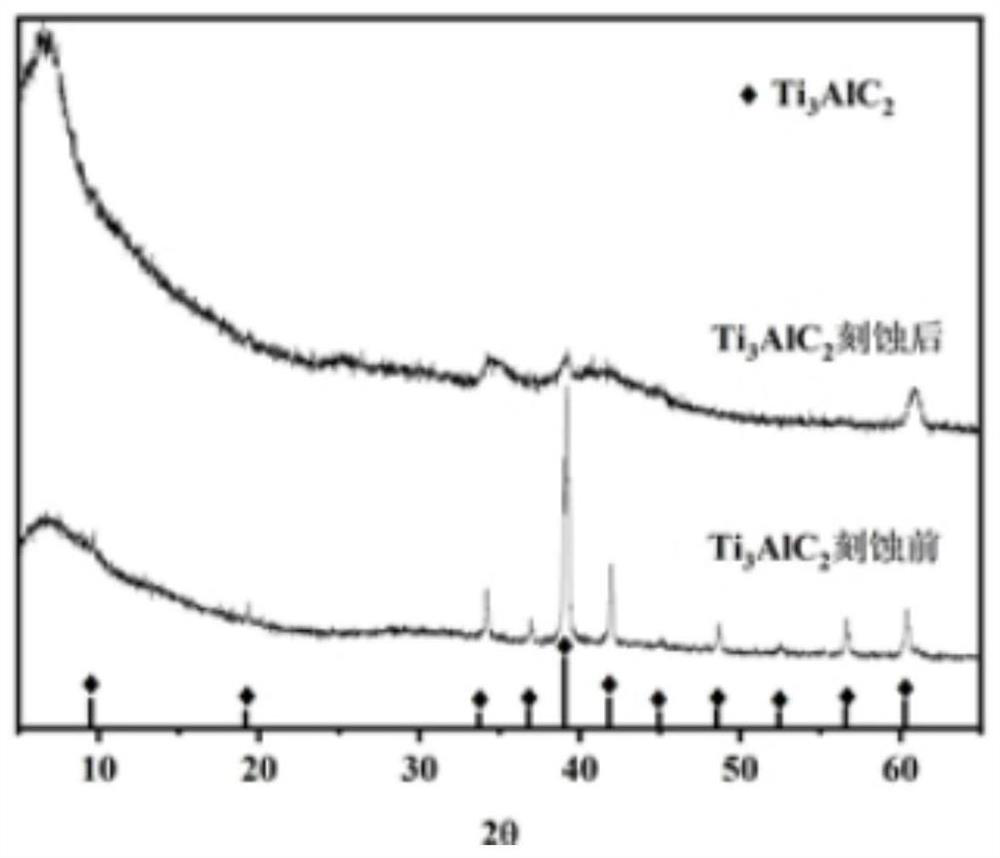

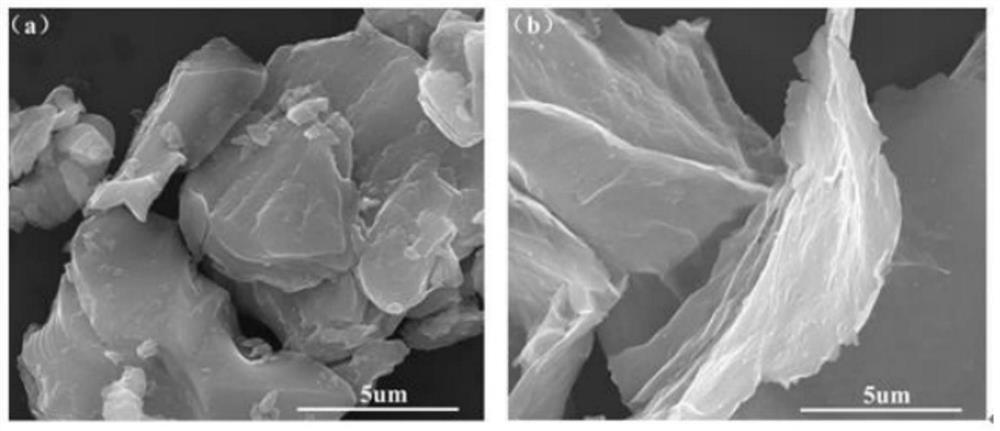

[0028] refer to Figure 1-5 , a preparation method of MXene / NiCoP / NF composite material, comprising: S1, taking lithium fluoride and hydrochloric acid solution, magnetic stirring in polytetrafluoroethylene reactor;

[0029] S2, take Ti 3 AlC 2 Slowly add to the solution in step S1, and stir magnetically under water bath conditions;

[0030] S3, ultrasonically dispersing the solution in step S2, and then centrifugally washing with deionized water until neutral;

[0031] S4. Centrifuge the neutral solution washed in step S3 with absolute ethanol, and collect the dark green supernatant;

[0032] S5. Freeze-dry the above dark green solution for 48 hours to obtain MXene.

[0033] S6. Cut the nickel foam into 2*4cm 2 , soaked in acetone solution and hydrochloric acid solution respectively, then cross-washed with deionized water and absolute ethanol, and dried in a vacuum drying oven;

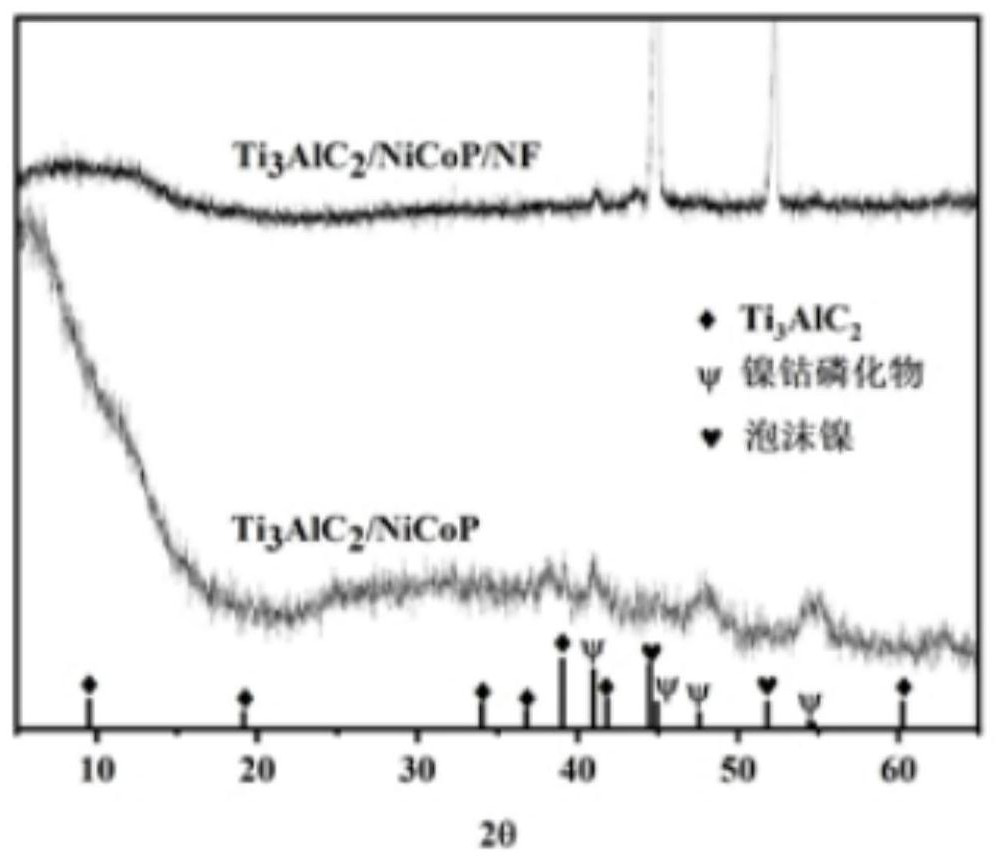

[0034] S7, take step S5 to prepare 10 mg of MXene, then dissolve 1 mmol of nickel nitrate he...

Embodiment 1

[0043] This embodiment provides a method for preparing a MXene / NiCoP / NF composite material, the specific steps are as follows:

[0044] 1) Take 1g of lithium fluoride and 9M 20mL hydrochloric acid solution, and magnetically stir at 400rpm in a polytetrafluoroethylene reactor for 30 minutes;

[0045] 2) Take 1g Ti 3 AlC 2 Slowly add to the solution in 1), and stir magnetically for 24 hours in a water bath at 40°C; 3) Disperse the solution in 2) by ultrasonic (750W) for 1 hour, then centrifuge with deionized water (8000rpm) and wash until neutral;

[0046] 4) Centrifuge the solution neutralized in 3) with absolute ethanol (3500rpm), and collect the dark green supernatant;

[0047] 5) The above dark green solution was freeze-dried for 48 hours to obtain MXene. 6) Cut the nickel foam into 2*4cm 2 , soaked in acetone solution and 2M hydrochloric acid solution for 30 minutes, then cross-washed 6 times with deionized water and absolute ethanol, and dried in a vacuum oven for 12 h...

Embodiment 2

[0050] This embodiment provides a method for preparing a MXene / NiCoP / NF composite material, the specific steps are as follows:

[0051] 1) Take 1g of lithium fluoride and 9M 20mL hydrochloric acid solution, and magnetically stir at 400rpm in a polytetrafluoroethylene reactor for 30 minutes;

[0052] 2) Take 1g Ti 3 AlC 2 Slowly add to the solution in 1), and stir magnetically for 24 hours in a water bath at 40°C; 3) Disperse the solution in 2) by ultrasonic (750W) for 1 hour, then centrifuge with deionized water (8000rpm) and wash until neutral;

[0053] 4) Centrifuge the solution neutralized in 3) with absolute ethanol (3500rpm), and collect the dark green supernatant;

[0054] 5) The above dark green solution was freeze-dried for 48 hours to obtain MXene.

[0055] 6) Cut the nickel foam into 2*4cm 2 , respectively soaked in acetone solution and 2M hydrochloric acid solution for 30 minutes, then cross-washed 6 times with deionized water and absolute ethanol, and dried in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com