Platinum-carbon catalyst for hydrogen fuel cell and preparation method of platinum-carbon catalyst

A platinum-carbon catalyst, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large sintering of active component particles, low activity, poor dispersion, etc., to improve electrochemical performance, alleviate The effect of sintering growth and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A hydrogen fuel cell platinum-carbon catalyst and a preparation method thereof of the present invention comprise:

[0047] 1. Remove organic impurities

[0048] (1) Washing: Mix the carbon carrier and the organic solvent, and stir mechanically at room temperature for 1 to 5 hours;

[0049] Wherein the mass ratio of the carbon carrier to the organic solvent used is 1:40~1:100;

[0050]Organic solvents include one or more of benzene, toluene, pentane, hexane, octane, cyclohexane, acetone, carbon tetrachloride, methanol, ethanol, isopropanol, dimethylformamide, etc. in any proportion mixture.

[0051] Carbon supports include one or a mixture of two or more of XC-72, XC-72R, Ketjen black series, Black Pearls 2000, acetylene black, graphene, and carbon nanotubes.

[0052] (2) Filtration / rinsing: the mixture in step (1) is filtered, the liquid is drained and rinsed with absolute ethanol several times.

[0053] Among them, the number of rinsing is not less than 3 times.

...

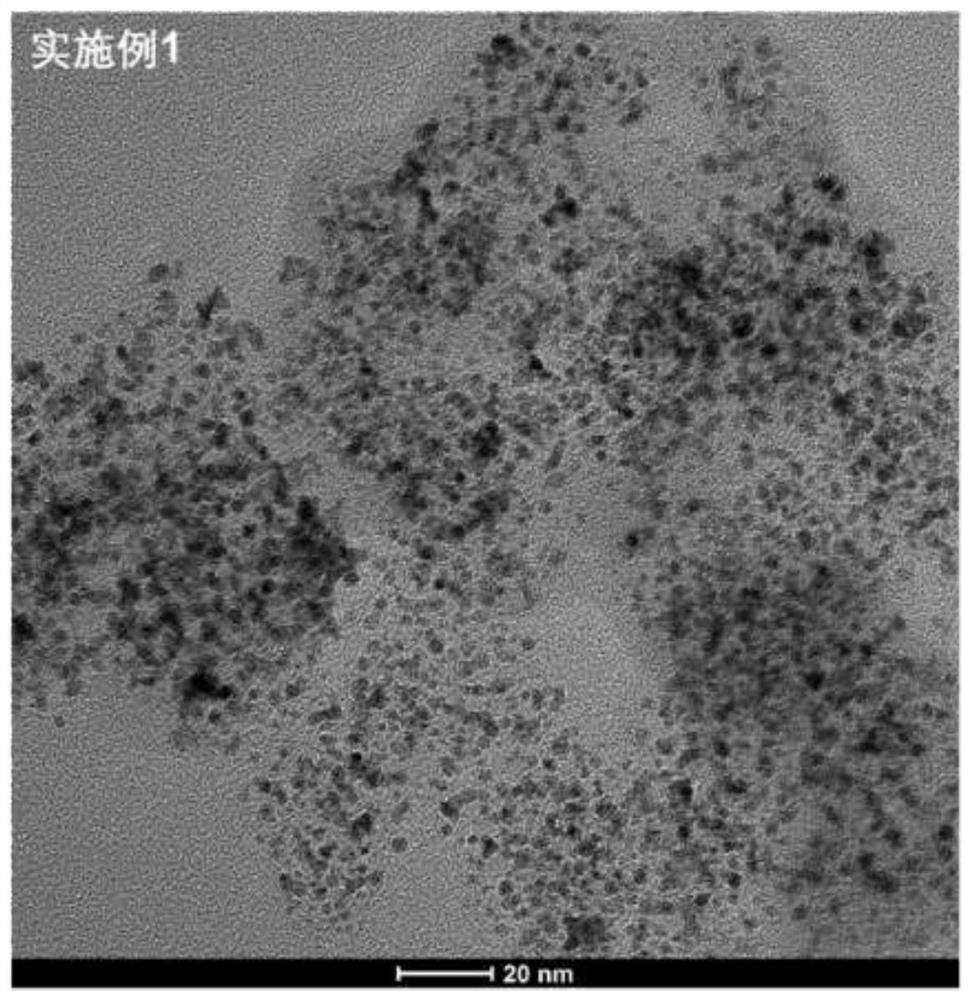

Embodiment 1

[0068] 1. Weigh 2g of original carbon carrier and 100g of acetone, and stir mechanically at room temperature for 5 hours;

[0069] 2. Remove the filtrate from the sample in step 1, rinse it with alcohol several times, and finally put it in an oven at 80°C for 12 hours;

[0070] 3. The dried sample in step 2 is crushed with a crusher;

[0071] 4. Mix 1 g of the carbon carrier obtained in step 3 with 40 g of 2M nitric acid solution, and stir at 60°C for 12 hours;

[0072] 5. Remove the filtrate from the sample in step 4, wash it with deionized water until the filtrate is neutral, and dry it in vacuum at 80°C;

[0073] 6. Take 120 mg of the sample in step 5, stir and ultrasonically disperse it in 12 mL of 1% PVP absolute ethanol solution with a mass fraction of 1% for 30 minutes, and then reflux at 60°C for 5 hours;

[0074] 7. Suction filter the product in step 6, then vacuum dry at 80°C for 12 hours;

[0075] 8. Take 40 mL of platinum nitrate solution with a concentration of...

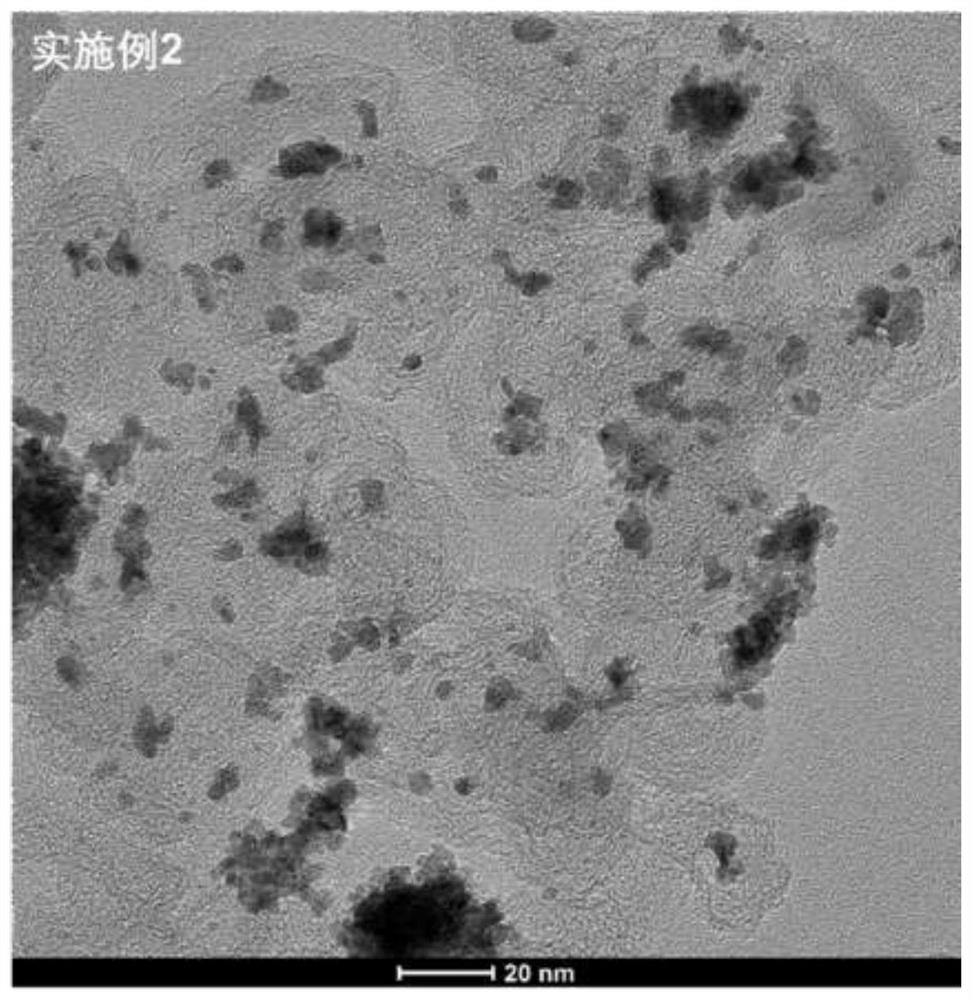

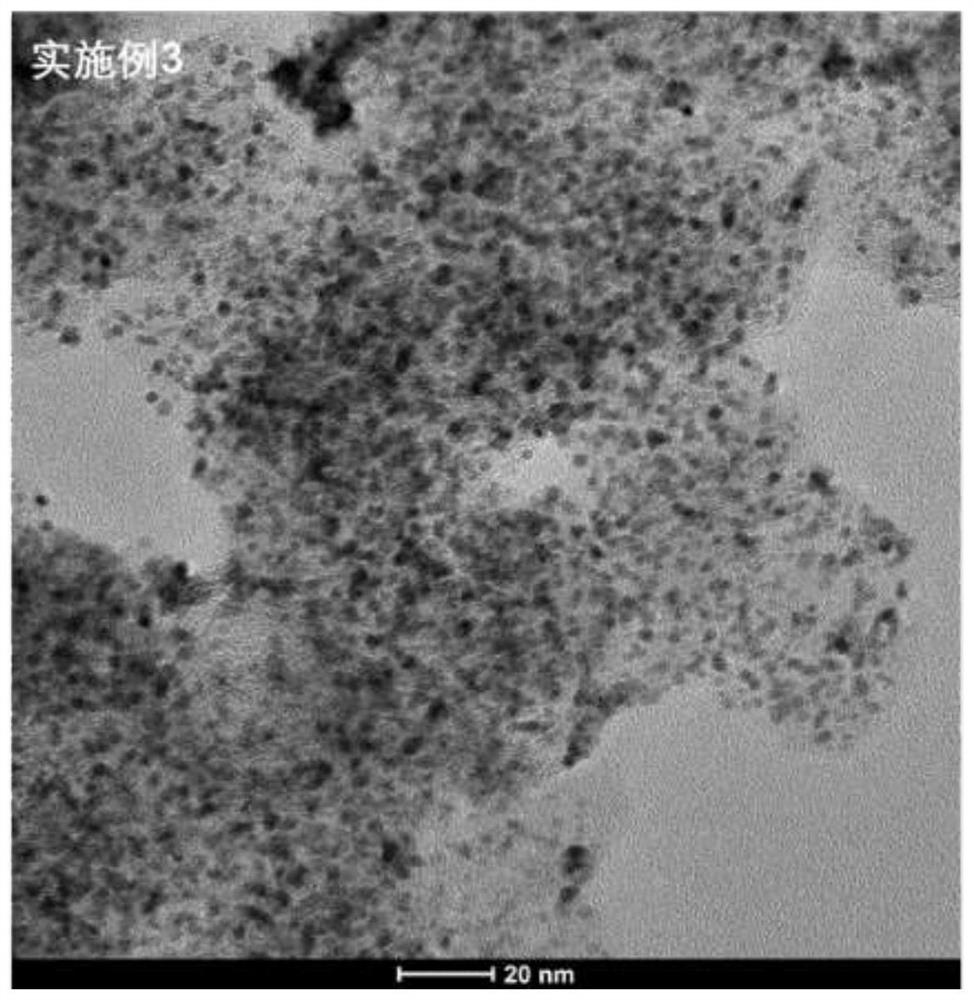

Embodiment 2

[0079] 1. Weigh 2g of the original carbon carrier and 100g of acetone, and stir mechanically at room temperature for 5 hours;

[0080] 2. Remove the filtrate from the sample in step 1, rinse it with alcohol several times, and finally put it in an oven at 80°C for 12 hours;

[0081] 3. The dried sample in step 2 is crushed with a crusher;

[0082] 4. Mix 1 g of the carbon carrier obtained in step 3 with 40 g of 2M nitric acid solution, and stir at 60°C for 12 hours;

[0083] 5. Remove the filtrate from the sample in step 4, wash it with deionized water until the filtrate is neutral, and dry it in vacuum at 80°C;

[0084] 6. Take 40 mL of platinum nitrate solution with a concentration of 5 mg / ml, and adjust the pH to 3-3.5 with 0.05 M hydrochloric acid solution, then add 4 mg of dopamine and mix and stir for 30 minutes, then add 120 mg of carbon carrier obtained in step 5, and stir mechanically 5 hours, and then 80 ° C rotary evaporation to dryness to remove water and then gro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap