Organic fertilizer based on waste alcohol fermentation wastewater

A technology for alcoholic fermentation wastewater and organic fertilizers, which is applied to organic fertilizers, fertilizers made from biological wastes, fertilizer mixtures, etc. performance, improved surface roughness, and the effect of avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

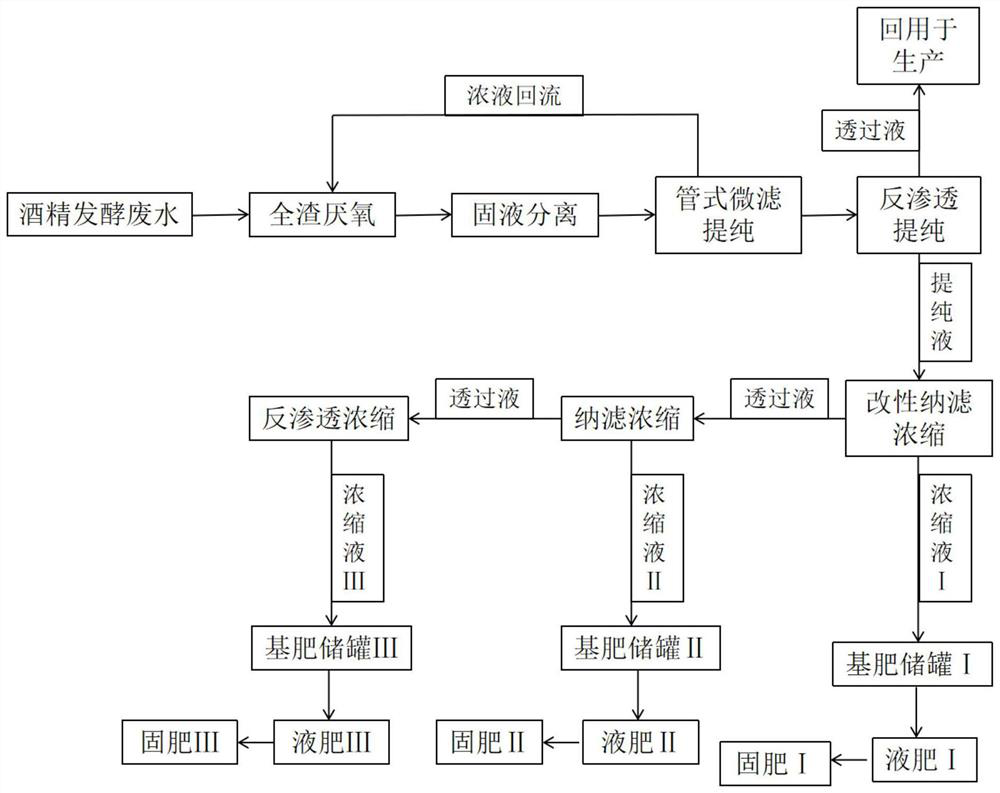

Image

Examples

Embodiment 1~4

[0035] A kind of organic fertilizer based on waste alcohol fermentation waste water is alcohol fermentation waste liquid obtained through the following steps:

[0036] S1. Anaerobic: Send the slag-containing alcohol fermentation wastewater into the anaerobic tank for anaerobic treatment of the whole slag. There are fillers and anaerobic bacteria covering the filler in the anaerobic tank. The anaerobic filler is composed of the following components: As shown in Table 1; the purpose of the above-mentioned anaerobic is to produce the highest concentration of humic acid, not to eliminate COD to the greatest extent in the traditional sense. Specifically, the anaerobic cycle of the anaerobic treatment is 10 days;

[0037] Table 1

[0038] components Example 1 Example 2 Example 3 Example 4 High-density polyethylene 100 copies 90 copies 92 copies 97 copies calcium carbonate 10 copies 5 copies 6 servings 8 servings stearic acid 5 copies...

Embodiment 1

[0050] Nutrient ingredient is urea among the embodiment 1, and trace element is formed by mixing the trace element in organism and the trace element in non-organism with weight ratio 1:5, and the trace element in described organism is cobalt, and the trace element in non-organism Trace elements in living organisms are rare earths.

Embodiment 2

[0051] Nutrient ingredient is ammonium polyphosphate in embodiment 2, and trace element is formed by mixing trace element in organism and non-organism with weight ratio 1:4, and the trace element in described organism is cobalt, so The trace elements in the above-mentioned non-biological organisms are rare earths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com