Multi-center bonded neutral polymer bonding agent and preparation method thereof

A polymer and multi-center technology, applied in the direction of offensive equipment, compressed gas generation, non-explosive/non-thermal agent components, etc., can solve the problems of limited improvement in the mechanical properties of propellants, and achieve good industrial production prospects and preparation methods Simple, surface-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

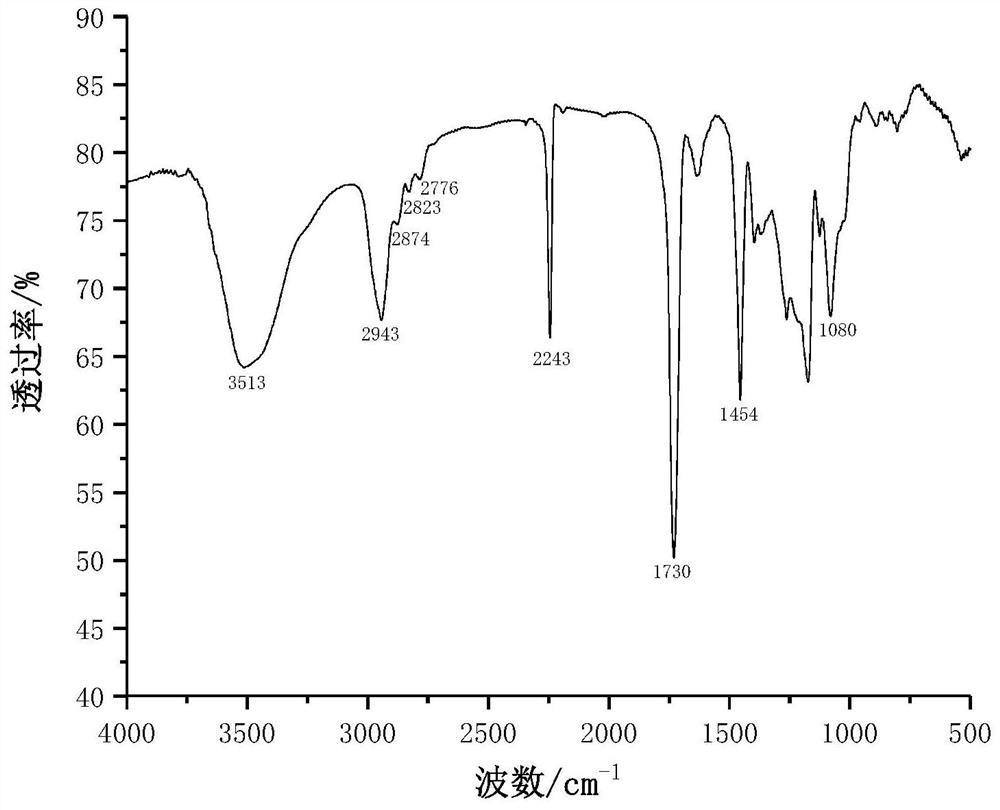

Embodiment 1

[0036] A kind of multi-center bonded neutral polymer bonding agent, its chemical structural formula is:

[0037]

[0038] The preparation method of above-mentioned bonding agent, comprises the following steps:

[0039] (1) By the weight of each unit, 28g acrylonitrile, 7g amino compound monomer, 8g hydroxyethyl acrylate are mixed to obtain mixed monomer, wherein the preparation steps of amino compound monomer are as follows:

[0040] 48.0g methyl methacrylate, 17.8g dimethylaminoethanol, 60ml n-hexane, 1.44g lithium hydroxide, 0.05g p-hydroxyanisole, react in a water bath at 70°C for 8 hours, and depressurize at 10mmHg and 80°C to obtain amino monomer;

[0041] (2) By weight, add 1.72g of azobisisobutyronitrile, 1.63g of β-mercaptoethanol, and 80ml of acetone into the reactor, stir and dissolve to obtain a mixed solution;

[0042] (3) Heating the mixed solution to 65°C, stirring at a speed of 300r / min, and reacting for 6 hours;

[0043] (4) Add the reaction solution in s...

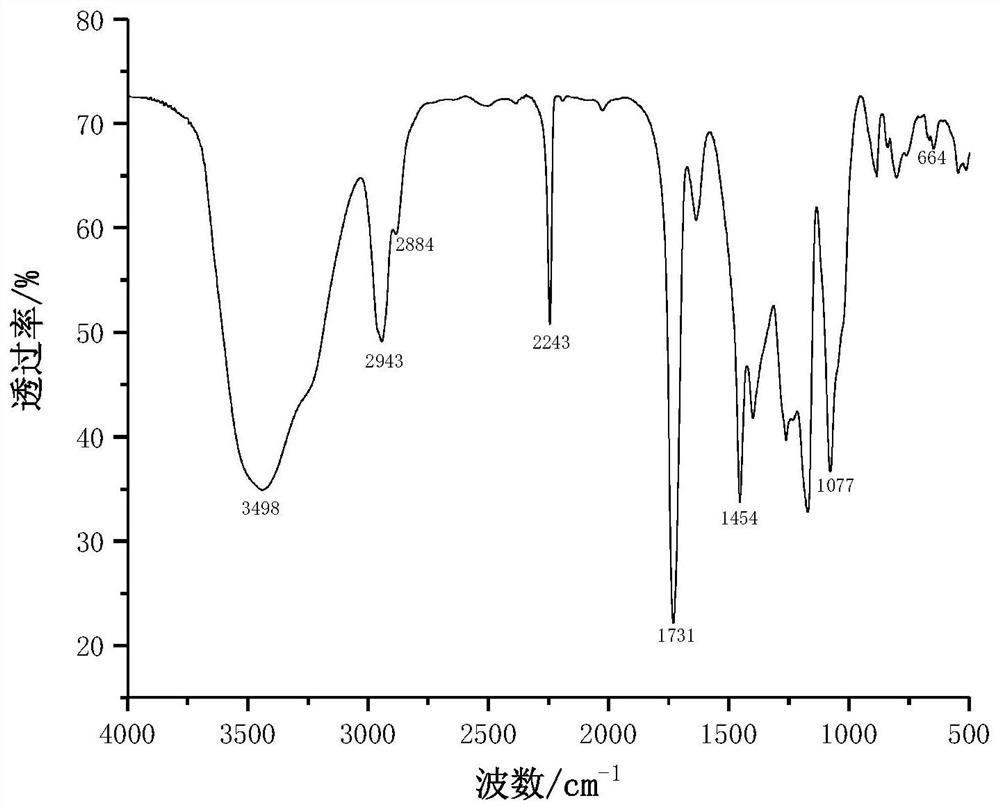

Embodiment 2

[0047] A kind of multi-center bonded neutral polymer bonding agent, its chemical structural formula is:

[0048]

[0049] The preparation method of above-mentioned bonding agent, comprises the following steps:

[0050] (1) By the weight of each unit, 28g acrylonitrile, 7g organic borate monomer, 8g hydroxyethyl acrylate are mixed to obtain mixed monomer, wherein the preparation steps of organic borate monomer are as follows:

[0051] Mix 46.0g n-butyl borate and 16.2g propylene glycol and heat up to 95°C. Distill under reduced pressure until no more liquid flows out. After 1 hour, add 25.52g hydroxyethyl acrylate and 0.05g p-hydroxyanisole, and continue to distill under reduced pressure to No fractions, resulting in organoborate monomers;

[0052] (2) By weight, add 1.72g of azobisisobutyronitrile, 1.63g of β-mercaptoethanol, and 80ml of acetone into the reactor, stir and dissolve to obtain a mixed solution;

[0053] (3) Heating the mixed solution to 65°C, stirring at a spe...

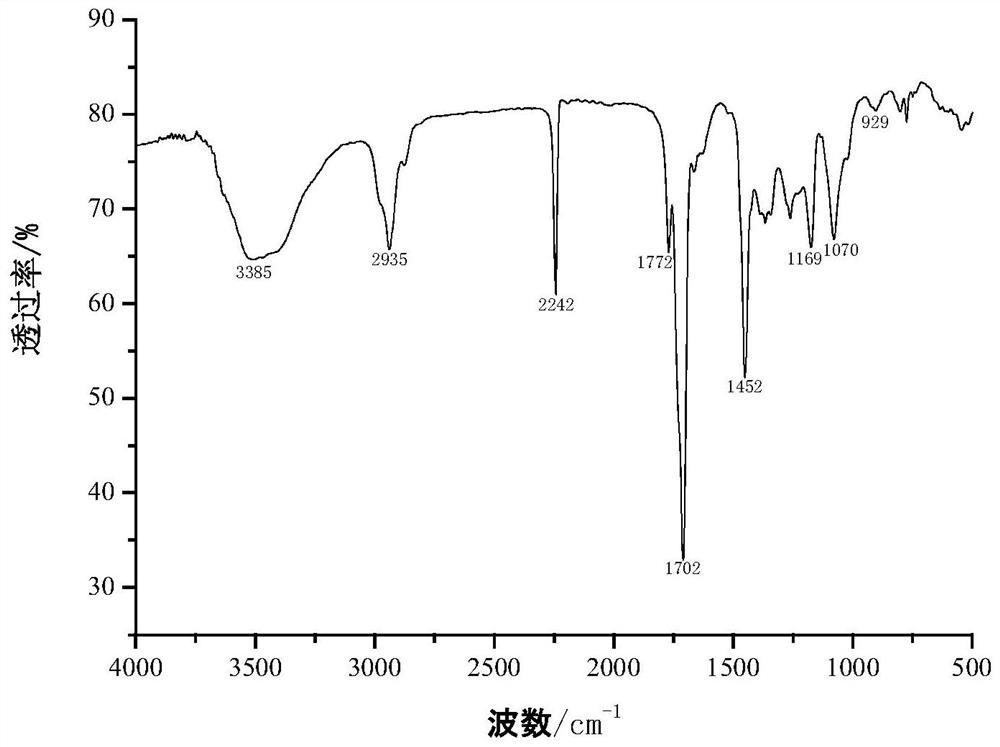

Embodiment 3

[0058] A kind of multi-center bonded neutral polymer bonding agent, its chemical structural formula is:

[0059]

[0060] The preparation method of above-mentioned bonding agent, comprises the following steps:

[0061] (1) By the weight of each unit, 28g acrylonitrile, 7g 3-allylhydantoin monomer, and 8g hydroxyethyl acrylate are mixed to obtain a mixed monomer, wherein the preparation of 3-allylhydantoin monomer Proceed as follows:

[0062] Mix 80ml of methanol, 200ml of distilled water, 22.44g of potassium hydroxide, and 40.03g of hydantoin, heat up to 60°C, keep stirring for 0.5h, then add 48.40g of 3-bromopropene dropwise, react at 60°C for 4h, and spin evaporate the reaction solution to obtain crude The product was recrystallized twice with n-hexane, and 3-allylhydantoin monomer was obtained after suction filtration;

[0063] (2) By weight, add 1.72g of azobisisobutyronitrile, 1.63g of β-mercaptoethanol, and 80ml of acetone into the reactor and stir to dissolve to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com