Rubber filler

A filler and rubber technology, applied in the field of rubber fillers and modifiers, can solve problems such as poor compatibility of rubber, difficulty in forming tight bonds, difficulty in product quality control, etc., to increase strength and strengthen interaction Force, the effect of improving the quality of rubber products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

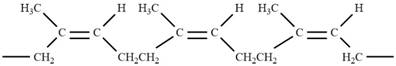

Method used

Image

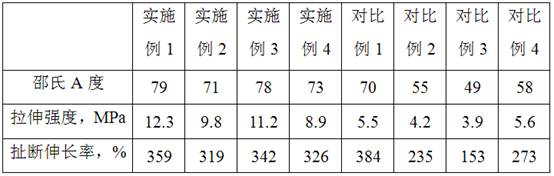

Examples

Embodiment 1

[0068] Provide a kind of rubber filling agent, comprise the component of following mass composition:

[0069] Modified solid: 52wt%;

[0070] Carbon black: 25wt%;

[0071] Sulfur: 3.5wt%;

[0073] Hexamethyltetramine: 2.5wt%;

[0074] Octylated diphenylamine: 3wt%;

[0075] Pine tar: 2wt%.

[0076] Wherein the modified solid preparation process is as follows:

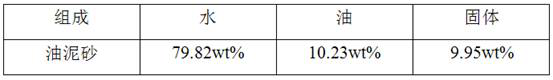

[0077] (1) Send the raw oil sludge sand into the sand washer for desanding treatment, and obtain the de-coarse oil sludge material, in which the solid particle size is between 41 and 83 μm;

[0078] (2) Send the de-coarse sand and oil sludge material in (1) into the dehydration and deoiling device, add flocculant polyaluminium chloride at a rate of 100 mg / L, and introduce micro-bubbles to mix with the material, and the material enters the settlement area through overflow , the material flocculates and settles and stratifies under the action of air flotation. The upper layer is a low-de...

Embodiment 2

[0081] Provide a kind of rubber filling agent, comprise the component of following mass composition:

[0082] Modified solid: 59wt%;

[0083] Carbon black: 17wt%;

[0085] Magnesium carbonate: 7wt%;

[0087] N,N'-diethylthiourea: 3wt%;

[0088] 2-mercaptobenzothiafile: 3wt%;

[0089] Paraffin: 1 wt%.

[0090] Wherein the modified solid preparation process is as follows:

[0091] (1) Send the raw oil sludge sand into the sand washer for desanding treatment, and obtain the de-coarse oil sludge material, in which the solid particle size is between 52 and 91 μm;

[0092] (2) Send the de-coarse sand and oil sludge material in (1) into the dehydration and deoiling device, add flocculant polymerized ferric sulfate at a rate of 90mg / L, and introduce micro-bubbles to mix with the material, and the material enters the settlement area through overflow, The material flocculates and settles and stratifies under the actio...

Embodiment 3

[0095] Provide a kind of rubber filling agent, comprise the component of following mass composition:

[0096] Modified solid: 42wt%;

[0097] Carbon black: 35wt%;

[0098] Sulfur dichloride: 5wt%;

[0100] Magnesium carbonate: 8wt%;

[0101] N,N'-diphenylthiourea: 3.5wt%;

[0102] 2-thiol benzothiazolate octyl salt: 4wt%;

[0103] Wherein the modified solid preparation process is as follows:

[0104] (1) Send the raw oil sludge sand to the sand washer for desanding treatment, and obtain the de-coarse oil sludge material, in which the solid particle size is between 32 and 72 μm;

[0105] (2) Send the de-coarse sand and oil sludge material in (1) to the dehydration and deoiling device, add flocculant polyaluminum chloride at a rate of 120 mg / L, and introduce micro-bubbles to mix with the material, and the material enters the settlement area through overflow , the material flocculates and settles and stratifies under the action of air flotation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com