Silicon carbide fin-shaped gate MOSFET integrated with channel diode

A technology that integrates channels and diodes. It is used in climate sustainability, semiconductor devices, electrical components, etc., and can solve the problems of high conduction loss, large turn-on voltage, increased on-resistance and reverse leakage current, etc. The effect of improving withstand voltage and reliability, reducing on-resistance, and reducing reverse conduction voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

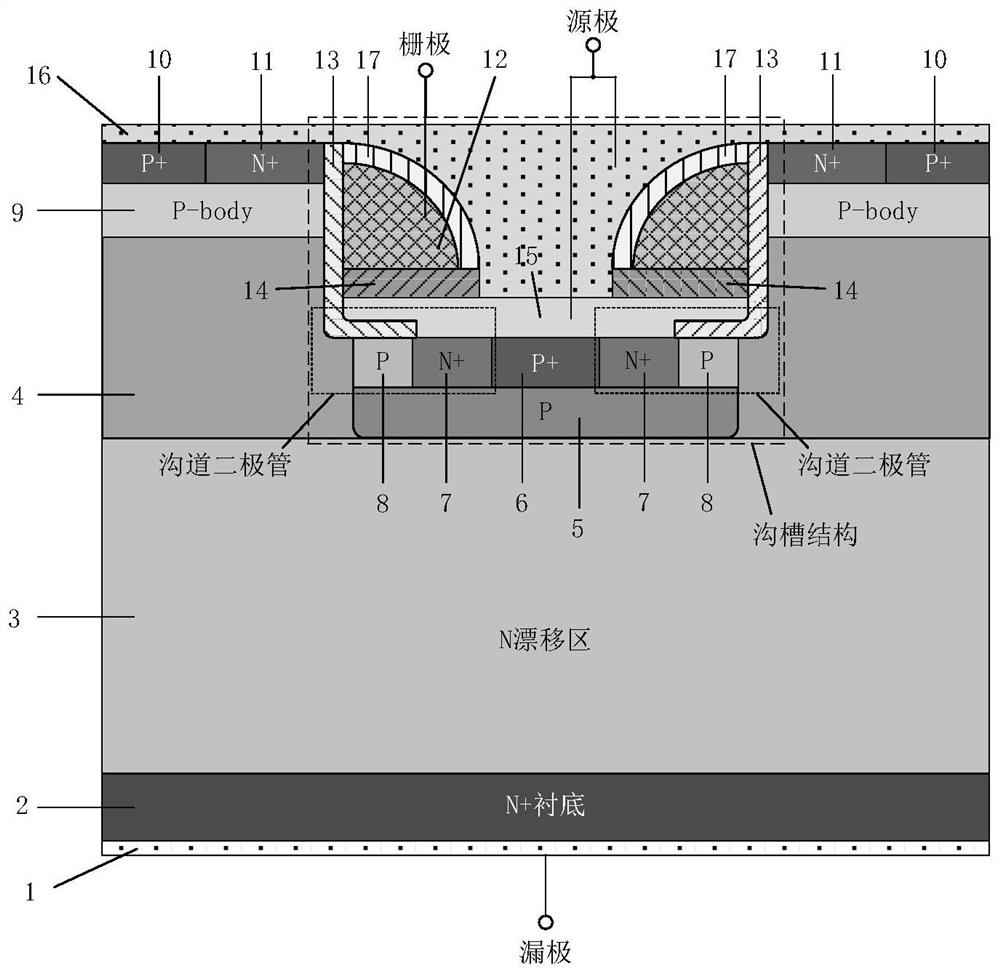

[0016] Such as figure 1 As shown, this example is a silicon carbide fin-gate MOSFET with integrated channel diode, which includes the first conductive material 1, N+ substrate layer 2, N drift region 3, epitaxial layer 4 and P -body region 9, the bottom of the first conductive material 1 is drawn out as a drain;

[0017] It is characterized in that it also includes a trench structure and a source region structure, the trench structure successively penetrates the P-body region 9 and the epitaxial layer 4 along the vertical direction, and then contacts the N drift region 3, and the source region structure is located in the trench The first P+ source contact region 10 and the first N+ source contact region 11 are arranged side by side on the upper surface of the P-body region 9 on both sides of the structure, wherein the first N+ source contact region 11 is in contact with the trench structure; the bottom of the trench structure is P The buried layer 5, the P buried layer 5 is i...

Embodiment 2

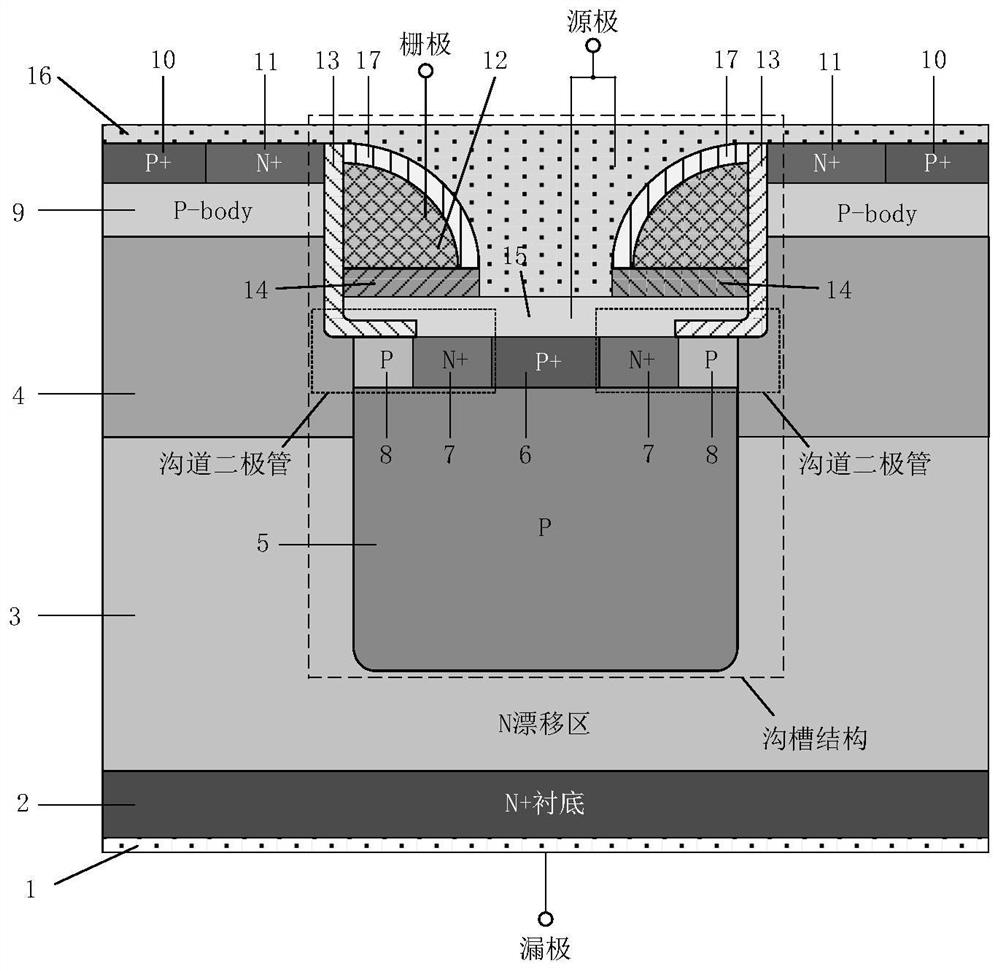

[0022] Such as figure 2 As shown, the difference between this example and Example 1 is that the P buried layer 5 extends downward into the N drift region 3, and the P buried layer 5 and the N drift region 3 form a semi-superjunction structure. In the off state, the semi-superjunction region forms a trapezoidal electric field distribution to improve the withstand voltage, and the higher doping concentration of the N drift region 3 in the forward conduction can reduce the on-resistance and improve the overall static characteristics of the device. Due to the existence of the P buried layer connected to the source potential at the bottom of the trench, the original gate-drain capacitance formed by the depletion of the bottom of the trench gate and the N drift region 3 will be converted into a gate-source capacitance, and the semi-superjunction structure will enhance this effect, making the device The gate-to-drain capacitance is further reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com