Method for synthesizing benserazide hydrochloride through continuous flow

A technology of benserazide hydrochloride and benzylhydrazone hydrochloride, which is applied in the fields of hydrazide preparation, hydrazone preparation, organic chemistry, etc., can solve the problems that are not conducive to improving production capacity and unavoidable excessive reaction impurities, and achieve small footprint and easy The effect of industrialized production and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

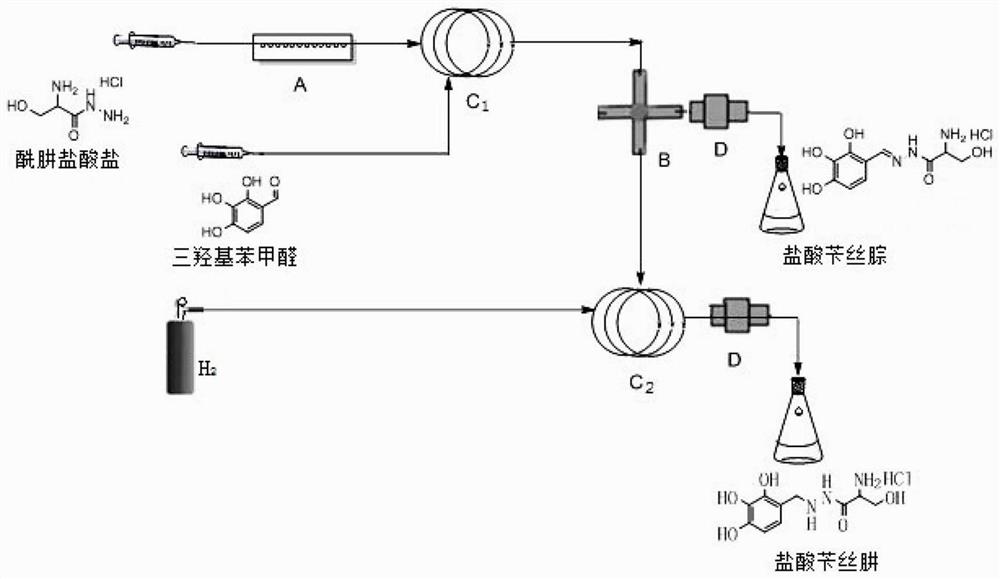

[0038] refer to figure 1 Flow chart of continuous flow synthesis of benserazide hydrochloride, figure 1 Among them, A is a heat exchanger, B is a flow divider, and the intermediate can be separated by valve adjustment or directly proceed to the next step of reaction: C is a tubular reactor, including a mixer, a horizontal tubular reactor, a vertical tubular reactor, Coiled tube reactors, U-shaped tube reactors, multi-tube parallel tube reactors, etc., D is a back pressure valve, which can automatically adjust the system pressure in real time, trace the process conditions of the flow chemical process, and then achieve reproducible reactions sex.

[0039] A method for continuous flow synthesis of benserazide hydrochloride, the method comprises the following steps:

[0040] S1: Pump 2mol / L ethanol solution of hydrazide hydrochloride (starting material) into heat exchanger A with a residence time of 0.5s, and then transport it to the first tubular reactor C at a flow rate of 10m...

Embodiment 2

[0046] S1: Pump 2mol / L ethanol solution of hydrazide hydrochloride (starting material) into heat exchanger A with a residence time of 0.5s, and then flow into the first tubular reactor C at a flow rate of 12ml / min 1 , the ethanol solution of the trihydroxybenzaldehyde of 2mol / L flows into the first tubular reactor C according to the flow velocity of 12ml / min 1 , react to obtain benzsilhydrazone hydrochloride;

[0047] S2: The benzsilhydrazone hydrochloride ethanol suspension obtained in S1 flows into the second tubular reactor C filled with palladium carbon catalyst 2 , the total flow rate is 30ml / min, and the residence time of 20s is maintained, while the second tubular reactor C 2 Into the hydrogen, to ensure that the second tubular reactor C 2 The internal pressure is 0.1Mpa;

[0048] S3: After continuously collecting the reaction solution, the organic phase is concentrated under reduced pressure, and ethanol is recovered to obtain crude product benserazide hydrochloride...

Embodiment 3

[0051] S1: Pump 2mol / L ethanol solution of hydrazide hydrochloride (starting material) into heat exchanger A with a residence time of 0.5s, then flow into the first tubular reactor C at 13ml / min 1 , the ethanolic solution of trihydroxybenzaldehyde with a concentration of 2mol / L flows into the first tubular reactor C according to the flow velocity of 13ml / min 1, the reaction obtains the ethanol solution of benzylhydrazone hydrochloride;

[0052] S2: The benzsilhydrazone hydrochloride ethanol suspension obtained in S1 flows into the second tubular reactor C filled with palladium carbon catalyst 2 , with a total flow rate of 40ml / min, maintaining a residence time of 20, while feeding the second tubular reactor C 2 Into the hydrogen, to ensure that the second tubular reactor C 2 The internal pressure is about 1.0Mpa;

[0053] S3: After continuously collecting the reaction solution, the organic phase is concentrated under reduced pressure, and ethanol is recovered to obtain crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com