Rapid perishable garbage degradation method and application thereof

A rapid degradation and garbage technology, applied in microorganism-based methods, biochemical equipment and methods, fixed on or in inorganic carriers, etc., can solve the problems of non-reusability, difficult separation of microbial carriers, etc., and achieve excellent microbial adsorption. efficiency, reduced preparation cost, and fast degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

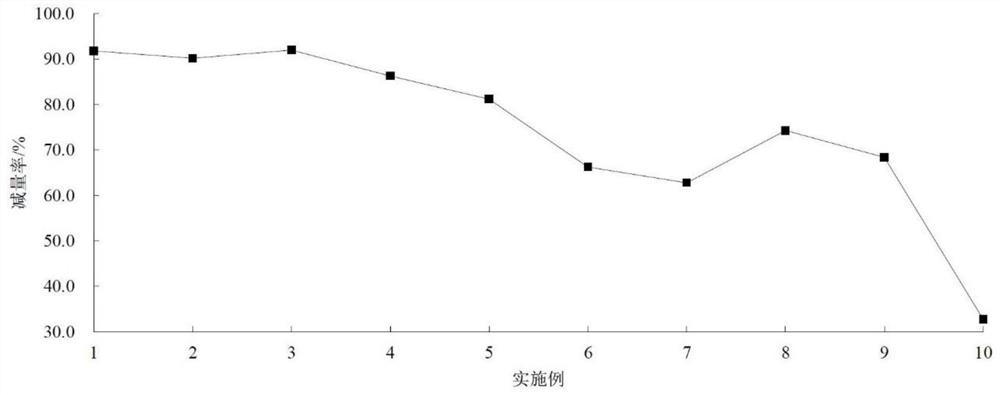

Embodiment 1

[0068] Embodiment 1: A kind of perishable rubbish degrading bacterial agent rapidly:

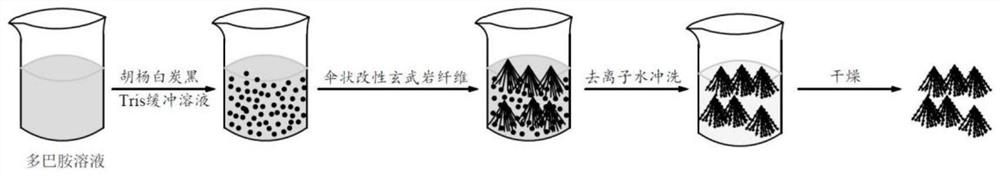

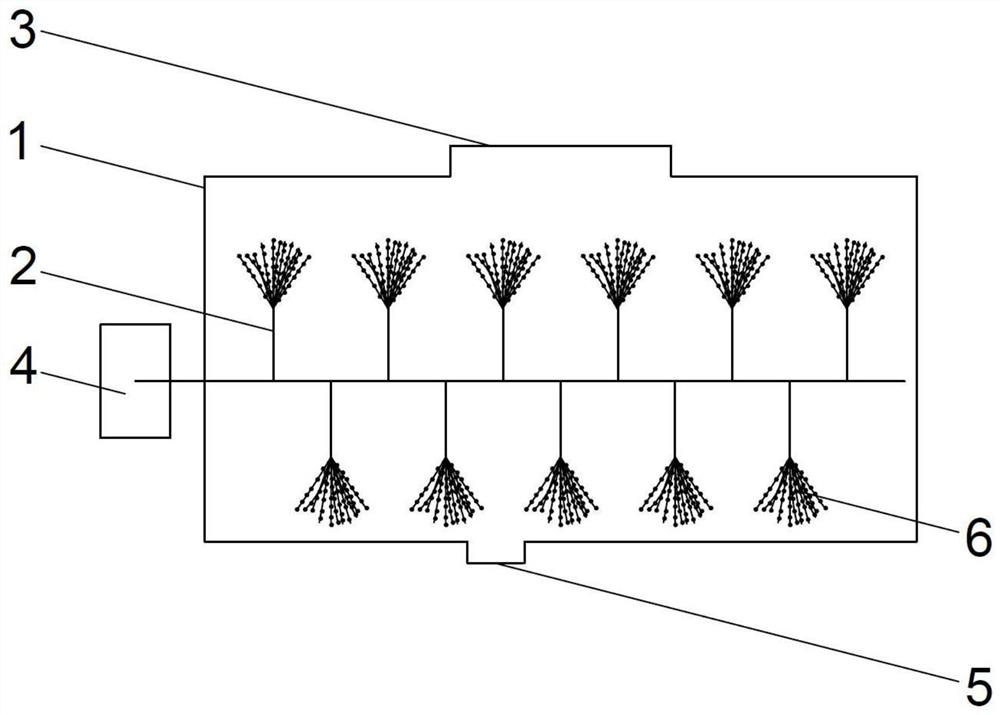

[0069] This embodiment first provides a reusable carrier, such as figure 1 As shown, its preparation steps specifically include:

[0070] 1) Basalt fiber (diameter 12μm) soaked in 5% acetone solution, at frequency 25KHz, density 0.3W / cm 2 Ultrasonic cleaning for 6 hours under the conditions, rinsed twice with deionized water, placed in 0.5mol / L hydrochloric acid solution, soaked at 35°C for 60 minutes, removed and rinsed until neutral, dried at 40°C for h, cut into 10cm length, and taken 15g basalt fiber, one end tied tightly into an umbrella shape;

[0071] 2) The ashes from the incinerated Populus euphratica branches were heated at 550°C for 2 hours, then dispersed in 0.2molL sodium hydroxide solution according to the mass ratio of Populus euphratica ash to sodium hydroxide of 1.3:1, and stirred at 45°C with a cover at 120r / min React for 6 hours, filter and wash the residue with distill...

Embodiment 2

[0076] Embodiment 2: A kind of perishable rubbish degrading bacterial agent rapidly:

[0077] This embodiment first provides a reusable carrier, the preparation steps of which specifically include:

[0078] 1) Basalt fiber (diameter 15μm) soaked in 20% acetone solution, at frequency 40KHz, density 0.6W / cm 2 Ultrasonic cleaning for 4 hours under the conditions, rinsed with deionized water for 4 times, placed in 1.0mol / L hydrochloric acid solution, soaked at 35°C for 30 minutes, removed and rinsed until neutral, dried at 60°C for 1 hour, cut into 15cm length, and taken 10g basalt fiber, one end tied tightly into an umbrella shape;

[0079] 2) The ashes from the incinerated Populus euphratica leaves were heated at 600°C for 2 hours, and then dispersed in 0.1mol / L sodium hydroxide solution according to the mass ratio of Populus euphratica ash to sodium hydroxide of 1.5:1. Stir and react for 2 hours. After filtering, take the residue and wash it with distilled water. After settli...

Embodiment 3

[0084] Embodiment 3: A kind of perishable rubbish degrading bacterial agent rapidly:

[0085] This embodiment first provides a reusable carrier, the preparation steps of which specifically include:

[0086] 1) Basalt fiber (diameter 15μm) soaked in 10% acetone solution, at frequency 32KHz, density 0.5W / cm 2 Ultrasonic cleaning for 5 hours under certain conditions, rinsed twice with deionized water, placed in 0.8mol / L hydrochloric acid solution, soaked at 35°C for 45 minutes, removed and rinsed until neutral, dried at 45°C for 2 hours, cut into 12cm length, and taken 15g basalt fiber, one end tied tightly into an umbrella shape;

[0087] 2) The ashes from the incinerated Populus euphratica leaves were heated at 580°C for 2 hours, then dispersed in 0.1mol / L sodium hydroxide solution according to the mass ratio of Populus euphratica ash to sodium hydroxide of 1.5:1, and covered at 50°C with a cover of 300 r / Stir and react for 3 hours. After filtering, take the residue and wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com