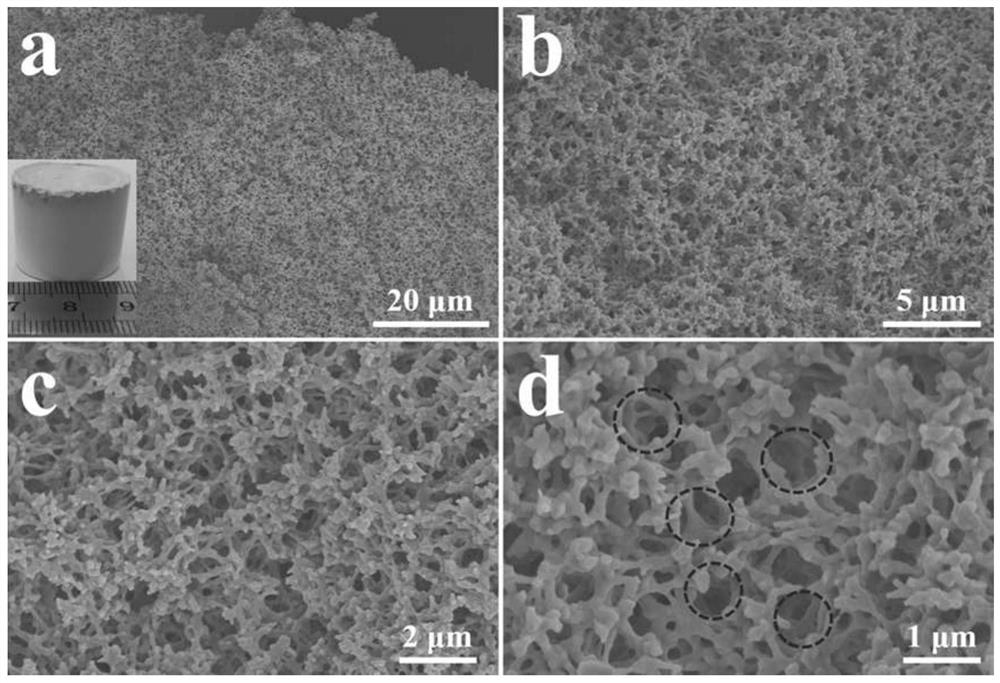

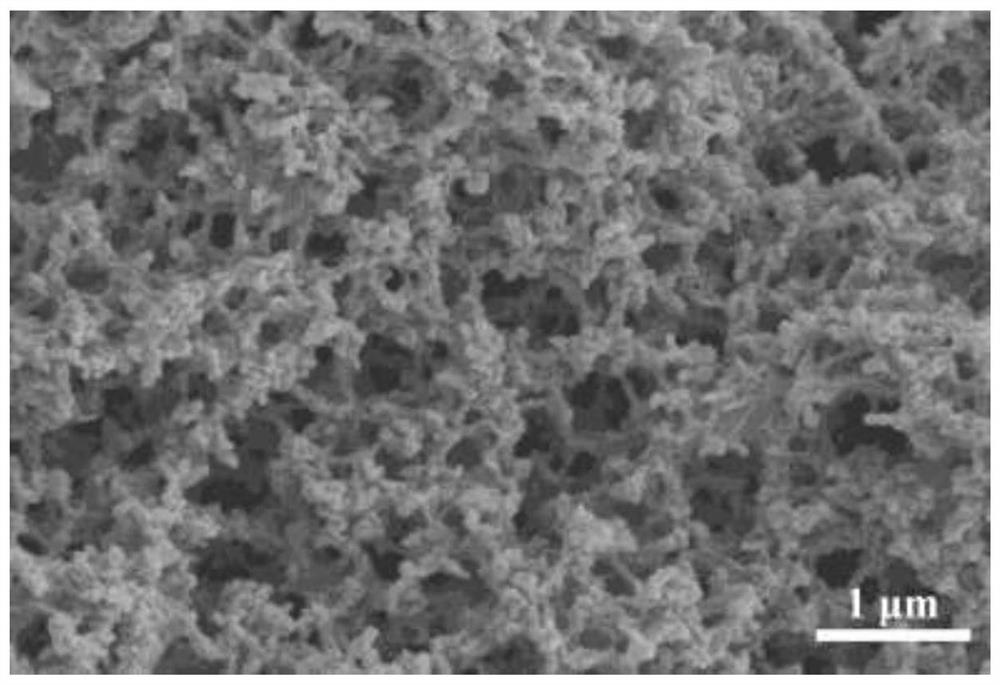

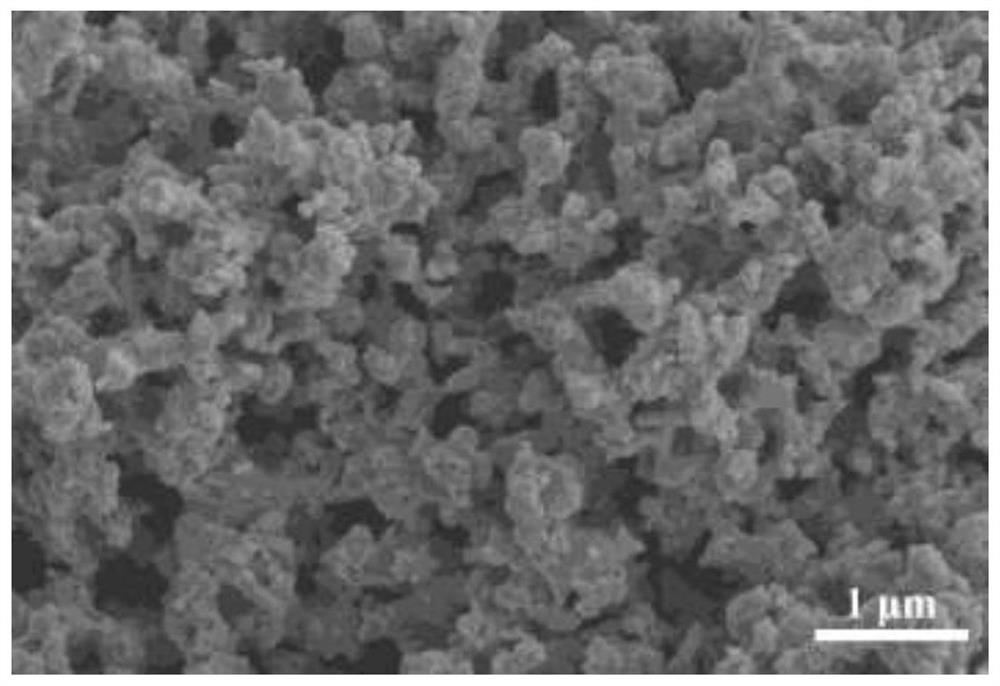

Preparation method of sulfide complete water splitting catalyst with three-dimensional co-continuous macroporous heterostructure

A heterogeneous structure, co-continuous technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of inability to obtain a macroporous skeleton structure and poor stability of the pore structure, achieve enhanced catalytic performance and stability, and increase the surface area , The effect of unique macroporous skeleton morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1, the preparation method of a stable three-dimensional co-continuous macroporous heterostructure sulfide total water splitting catalyst, the following steps are carried out in sequence:

[0058] 1), the preparation of nickel cobalt hydroxide macroporous gel, specifically as follows:

[0059] 1.1) Add 1.2ml of deionized water and 2.4ml of glycerin into a 10ml glass bottle, stir and mix evenly, as a solvent.

[0060] 1.2) Weigh 1 mmol of nickel chloride hexahydrate and 2 mmol of cobalt chloride hexahydrate, add them into the solvent obtained in step 1.1), and continue stirring evenly until a purple-brown solution is obtained.

[0061] 1.3), weigh 4g of polyacrylic acid aqueous solution with a mass concentration of 35%, slowly add (addition time is about 1 minute) to the solution obtained in step 1.2) under stirring, continue stirring (stirring time is about 5 minutes) until obtaining homogeneous sol;

[0062] The molecular weight of polyacrylic acid is 100,0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com