Copper inner electrode conductive paste for multilayer ceramic capacitor and application of copper inner electrode conductive paste

A technology of multi-layer ceramics and conductive paste, applied in the direction of fixed capacitor electrodes, laminated capacitors, capacitors, etc., can solve the problems of fast shrinkage, easy oxidation of copper paste, electron migration, etc., to prevent oxidation and improve the continuity of the copper layer , good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

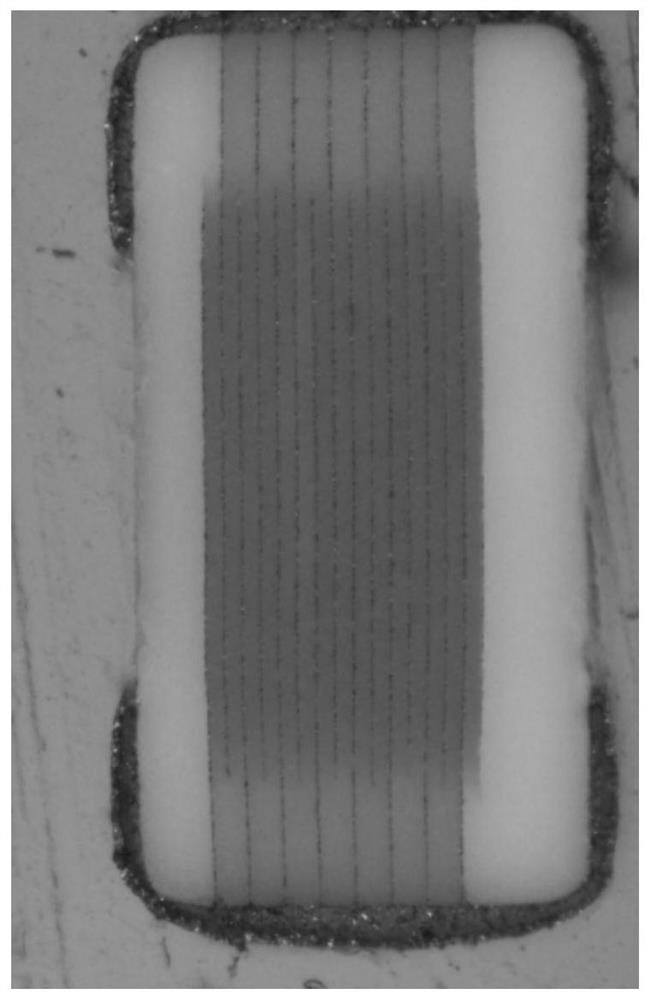

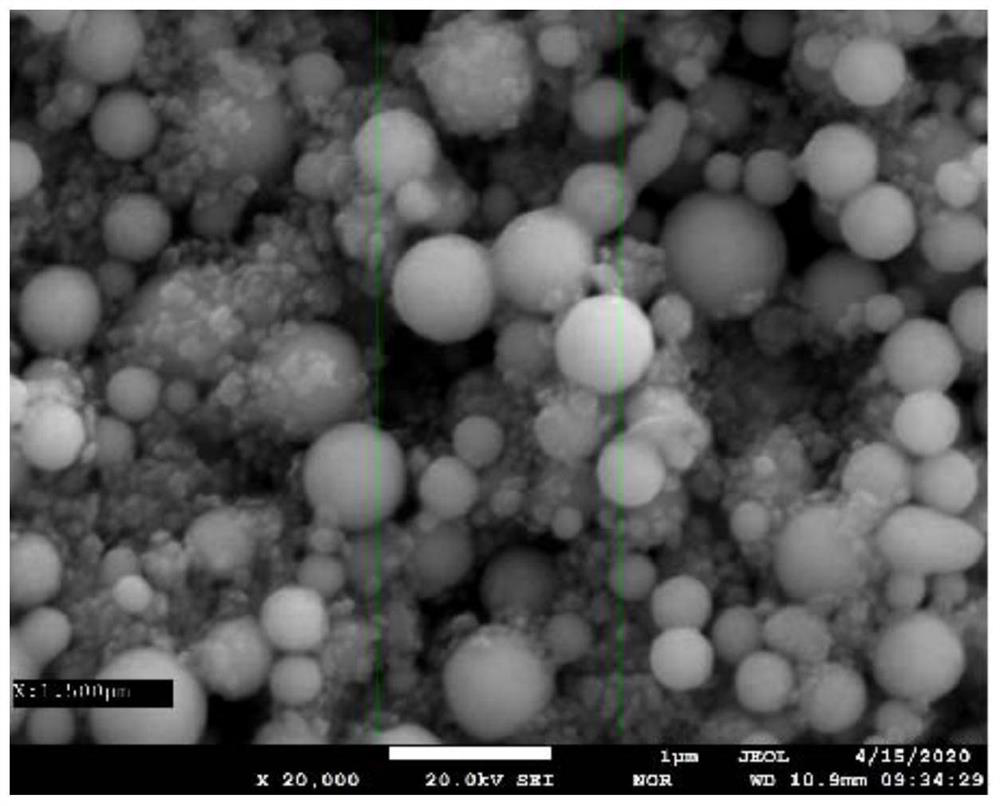

[0064] A method for preparing the above-mentioned multilayer ceramic capacitor copper internal electrode conductive paste, such as figure 2 Shown, the SEM figure of the conductive paste prepared for the inventive method and formula specifically comprises the following steps:

[0065] S1. Grinding of ceramic powder:

[0066] The ceramic powder is a mixture of zinc oxide, barium oxide and zirconia, prepare 45g, ball mill the ceramic powder, the ball milling speed is 12~16m / s, and ball mill until the specific surface area of the ceramic powder is less than or equal to 20m 2 / g and uniform particle size to prevent agglomeration and large particles;

[0067] S2, preparation of glue:

[0068] Mix and stir 300g of dihydroabietyl acetate, 13g of polyvinyl butyral and 0.6g of polyamide wax. The stirring time is 6 hours to 8 hours, the stirring temperature is 10-20°C, and the stirring speed is 800-1200 rpm / min, the obtained mixture is subjected to pressure filtration, the filtrat...

Embodiment 2

[0079] A method for preparing the above-mentioned multilayer ceramic capacitor copper internal electrode conductive paste, comprising the steps:

[0080] S1. Grinding of ceramic powder:

[0081] The ceramic powder is a mixture of zinc oxide, barium oxide and zirconia, prepare 50g, and ball mill the ceramic powder at a speed of 12 to 16m / s until the specific surface area of the ceramic powder is less than or equal to 20m 2 / g and uniform particle size to prevent agglomeration and large particles;

[0082] S2, preparation of glue:

[0083] 420g of terpineol, 15g of ethyl cellulose and 0.6g of polyamide wax were mixed and stirred, the stirring time was 6 hours to 8 hours, the stirring temperature was 10-20°C, and the stirring speed was 800-1200rpm / min, the obtained mixture Perform pressurized filtration, the filtration pressure is 2-4psi, and the filtration speed is 1-4L / min, to obtain the glue;

[0084] Weigh each substance according to the mass ratio of 5% to 15% of the gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com