Battery material, battery pole piece, preparation method of battery pole piece and battery

A technology of battery materials and battery pole pieces, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve problems such as large energy consumption, environmental pollution, toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a positive pole piece, which is prepared according to the following steps:

[0038] Under the environment of dew point -40°C in the drying room, take 9g of lithium iron phosphate, 0.8g of polymer binder PTFE, 0.1g of hot-melt polymer material PE, and 0.1g of conductive agent SP (conductive carbon black) for mechanical Stir to disperse, the stirring speed is 15000rpm, and the stirring time is 10min. After the stirring is finished, a mixture is obtained. The obtained mixture is heated and rolled, the temperature of the roller is 150°C, and the number of times of rolling is 1 time to obtain a flat self-supporting diaphragm with a thickness of 120um; the carbon-coated aluminum foil is used as the current collector, and the current collector and the diaphragm are rolled. Composite, the temperature of the roller is 100°C, the number of times of rolling is 2 times, and the positive electrode of the battery is obtained.

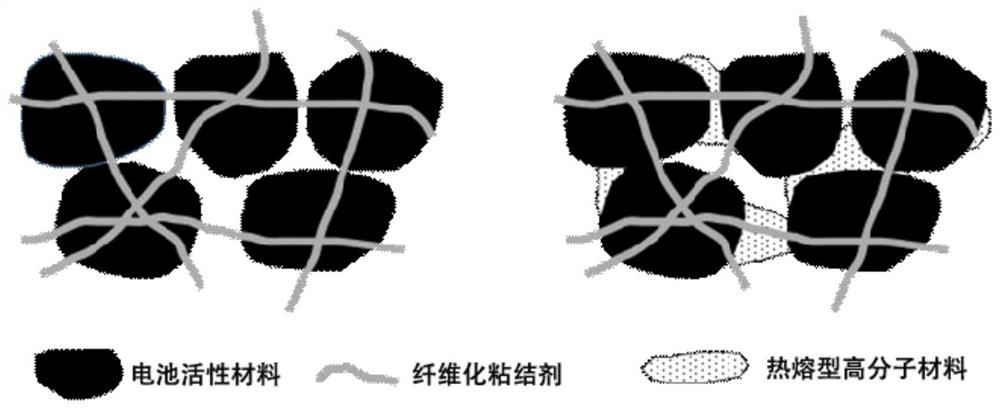

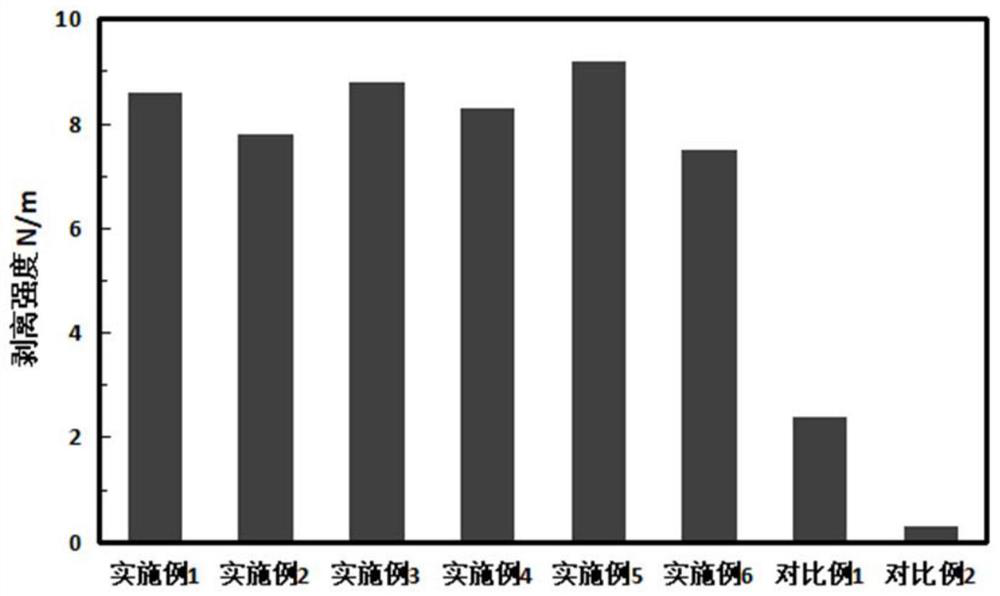

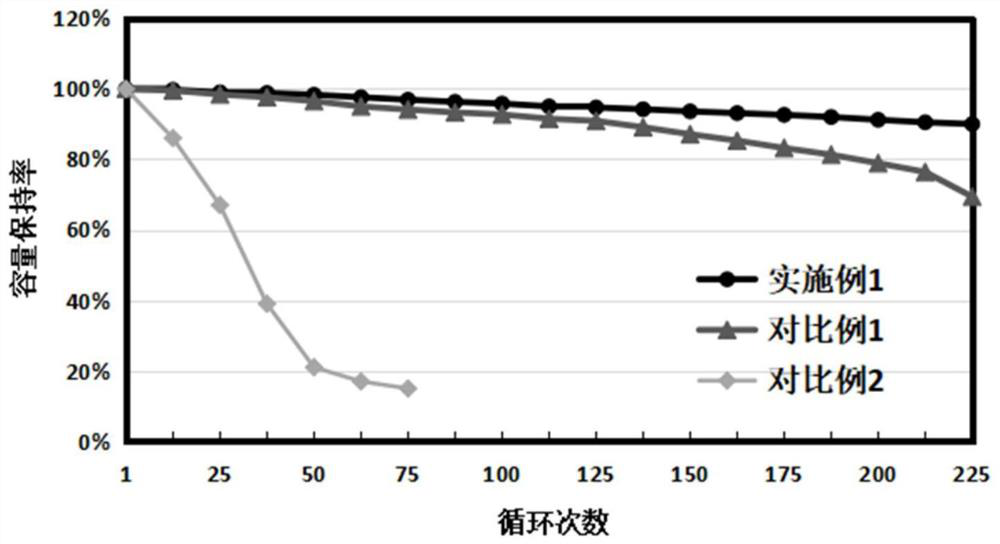

[0039] see figure 1 , figur...

Embodiment 2

[0041] This embodiment provides a positive pole piece, which is prepared according to the following steps:

[0042] In a drying room with a dew point of -45°C, take 9.2g of NCM811 (nickel-cobalt-manganese ternary material), 0.6g of polymer binder PTFE, 0.1g of hot-melt polymer material PMMA, and 0.1g of conductive agent Ketjen Black. g, carry out mechanical stirring and dispersing, the stirring speed is 18000rpm, and the stirring time is 20min. After the stirring is finished, a mixture is obtained. The obtained mixture is heated and rolled, the temperature of the roller is 140°C, and the number of times of rolling is 1 time to obtain a flat self-supporting diaphragm with a thickness of 70um; the carbon-coated aluminum foil is used as the current collector, and the current collector and the diaphragm are rolled. Composite, the temperature of the roller is 120°C, the number of times of rolling is 2 times, and the positive electrode sheet is obtained.

Embodiment 3

[0044] This embodiment provides a positive pole piece, which is prepared according to the following steps:

[0045] Take 8.6g of NCM523 (nickel-cobalt-manganese ternary material), 0.8g of polymer binder PTFE, 0.4g of hot-melt polymer material PP, and 0.2g of conductive agent acetylene black in a drying room with a dew point of -50°C , carry out mechanical stirring and dispersing, the stirring speed is 18000rpm, and the stirring time is 15min. After the stirring is finished, a mixture is obtained. The obtained mixture is heated and rolled, the temperature of the roller is 140°C, and the number of times of rolling is 1 time to obtain a flat self-supporting diaphragm with a thickness of 90um; the carbon-coated stainless steel foil is used as the current collector, and the current collector and the diaphragm are rolled Press and compound, the temperature of the roller is 100° C., and the number of times of rolling is 2 times to obtain the positive electrode of the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com