Polyethersulfone single-ion polymer and single-ion gel polymer electrolyte

A gel polymer and ionic polymer technology, applied in the field of single-ion gel polymer electrolyte, can solve problems affecting battery stability, affecting battery performance, accelerating lithium dendrite growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

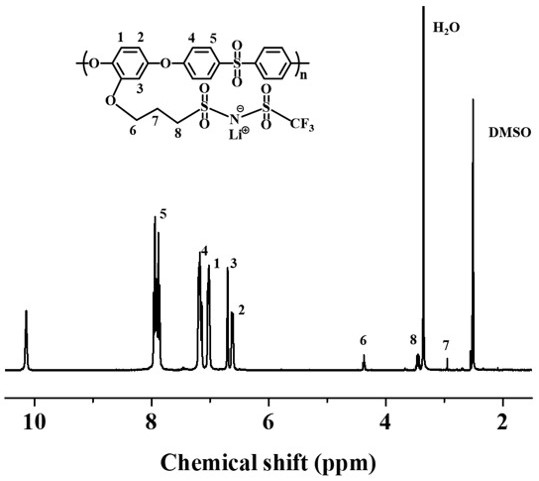

Examples

Embodiment 1

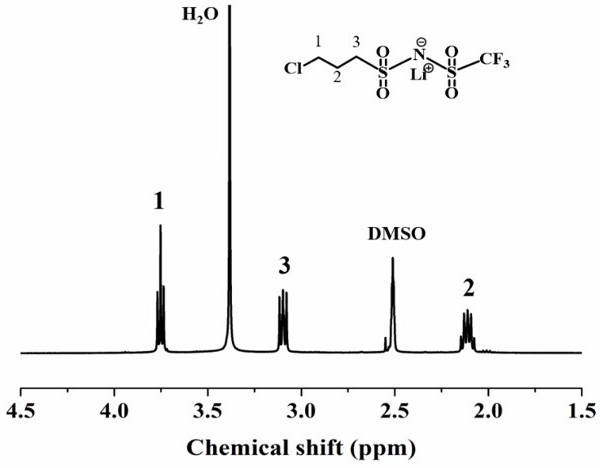

[0053] Example 1 Preparation of lithium 3-chloropropanesulfonyl (trifluoromethanesulfonyl)imide (LiCPSI)

[0054] Under a nitrogen atmosphere, add 20 mmol (2.9818 g) of trifluoromethanesulfonamide and 40 mmol (0.9572 g) of LiOH into 20 ml of anhydrous acetonitrile, and add 20 mmol (3.541 g) of ) of 3-chloropropanesulfonyl chloride. Subsequently, the reaction was carried out at room temperature for 24 h, acetonitrile was removed by rotary evaporation, and the obtained solid lithium 3-chloropropanesulfonyl(trifluoromethanesulfonyl)imide (LiCPSI) was recrystallized in dichloromethane, and 7.4125 g of white solid was obtained by filtration.

Embodiment 2

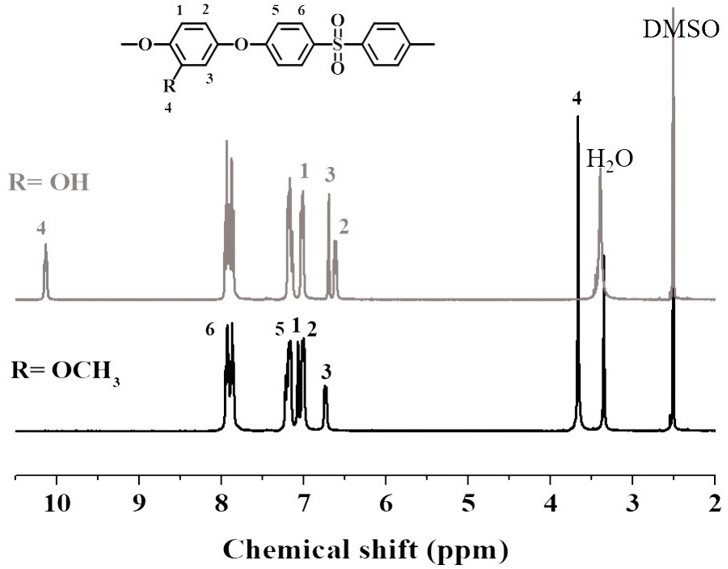

[0055] Example 2 Containing methoxy polyethersulfone (PES-OCH 3 ) preparation

[0056] In a three-necked flask equipped with a mechanical stirrer, a nitrogen inlet tube, a thermometer, and a water separator, add 5.6056 g of 2-methoxyhydroquinone (MHQ) and 10.17 g of 4,4'-difluorodiphenyl sulfone in sequence (FPS), 6.624 g of anhydrous potassium carbonate, 50 ml of sulfolane (TMS), and 18 mL of toluene were heated to 140-170 °C for 12 h under stirring with nitrogen gas to obtain a viscous solution, and then the viscous solution was added to distilled water. After cooling, the product is pulverized, washed with deionized water and ethanol, and dried to obtain methoxy-containing polyethersulfone (PES-OCH 3 ).

Embodiment 3

[0057] Example 3 Preparation of hydroxyl-containing polyethersulfone (PES-OH)

[0058] In a three-necked flask equipped with a mechanical stirrer, a nitrogen inlet tube, a thermometer, and a water separator, the PES-OCH obtained in 6 g of Example 2 was 3 Dissolve in anhydrous chloroform, add 60 ml of chloroform solution containing 10% boron tribromide dropwise at -40 °C, react at room temperature for 12 h, sink into ethanol, wash with deionized water and ethanol, and dry to obtain Hydroxypolyethersulfone (PES-OH).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com