Renewable high-barrier polyester packaging material and preparation method thereof

A packaging material and high-barrier technology, applied in flat products, other household appliances, applications, etc., can solve the problems of complex mold design, inability to recycle, and impossible to regain high-barrier packaging materials, achieving easy recycling, Excellent gas barrier properties, enhancing the effect of interfacial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

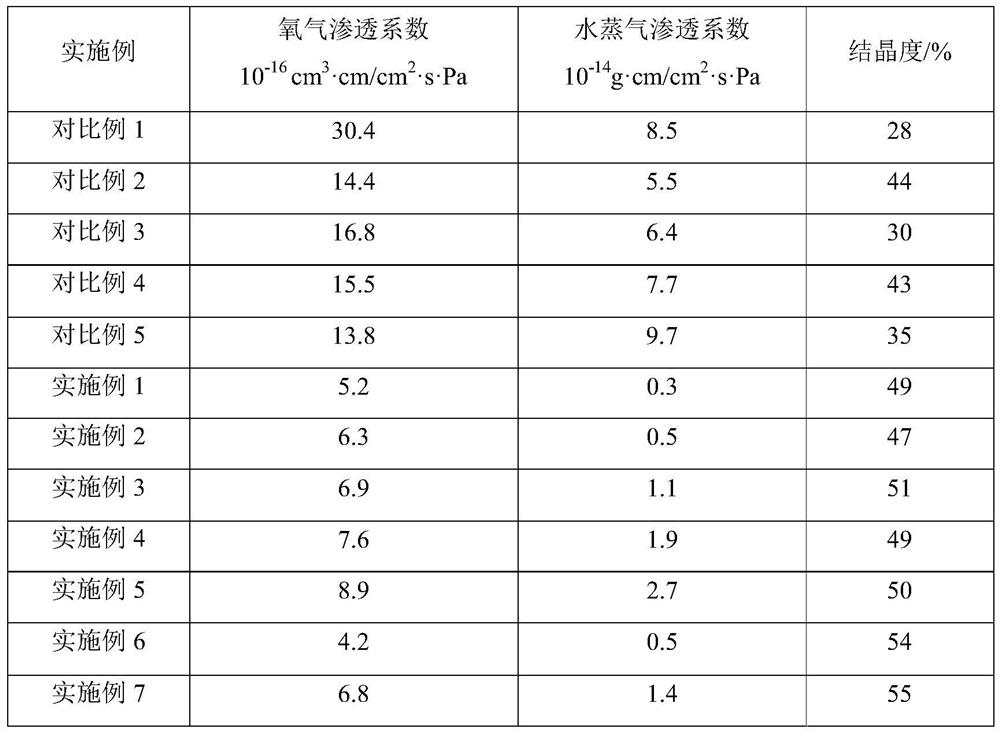

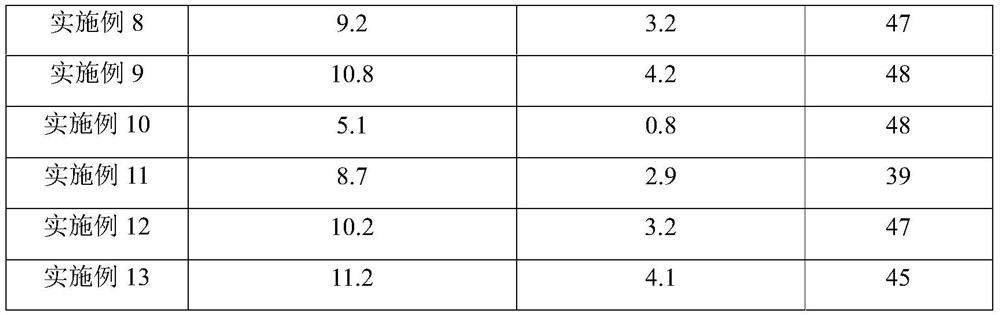

Examples

Embodiment 1

[0036] 60 parts of polyethylene terephthalate after drying, 40 parts of polyglycolic acid, ethylene-methyl acrylate-glycidyl methacrylate copolymer (glycidyl methacrylate mass content is 8%) 3 Parts, 0.3 parts of tris[2,4-di-tert-butylphenyl] phosphite were pre-mixed in a high-speed mixer for 2 minutes, put into the extruder through continuous melt extrusion and granulation, the screw temperature was 250 ° C, the screw speed 200rpm. The dried pellets were extruded into flakes by a screw extruder and rapidly cooled to 30°C, and the screw temperature was 260°C. A renewable high-barrier packaging material can be obtained by biaxially stretching the cooled sheet using a flat film biaxial stretching process, and then heat-treated and cooled to room temperature, where the stretching temperature is 90°C (polyethylene terephthalate 15°C above the glass transition temperature of the glycol ester), the heat treatment temperature is 130°C, the transverse stretching ratio is 8 times, and...

Embodiment 2

[0038] 70 parts of polyethylene terephthalate after drying, 30 parts of polyglycolic acid, ethylene-methyl acrylate-glycidyl methacrylate copolymer (glycidyl methacrylate mass content is 8%) 3 Parts, 0.3 parts of tris[2,4-di-tert-butylphenyl] phosphite were stirred in a high-speed mixer for 2 minutes, put into an extruder through continuous melt extrusion and granulation, the screw temperature was 250°C, and the screw speed was 200rpm . The dried pellets were extruded into flakes by a screw extruder and rapidly cooled to 30°C, and the screw temperature was 260°C. The cooled sheet is biaxially stretched by the flat film biaxial stretching process, and then heat-treated and cooled to room temperature to obtain a renewable high-barrier packaging material. The stretching temperature is 90°C, and the heat treatment temperature is 130°C. The transverse stretch ratio is 8 times, and the longitudinal stretch ratio is 8 times.

Embodiment 3

[0040] 80 parts of polyethylene terephthalate after drying, 20 parts of polyglycolic acid, 0.7 part of multi-epoxy functional group compatibilizer ADR4468, tetrakis[β-(3,5-di-tert-butyl-4-hydroxy 0.3 parts of phenyl) propionic acid] pentaerythritol ester were stirred in a high-speed mixer for 2 minutes, put into an extruder through continuous melt extrusion and granulation, the screw temperature was 250°C, and the screw speed was 200 rpm. The dried pellets were extruded into flakes by a screw extruder and rapidly cooled to 30°C, and the screw temperature was 260°C. The cooled sheet is biaxially stretched by the flat film biaxial stretching process, and then heat-treated and cooled to room temperature to obtain a renewable high-barrier packaging material. The stretching temperature is 90°C, and the heat treatment temperature is 130°C. The transverse stretch ratio is 8 times, and the longitudinal stretch ratio is 8 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stretch temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com