Catalyst for hydrogen production by methanol steam reforming, preparation method and application thereof, and reaction for hydrogen production by methanol steam reforming

A steam reforming and catalyst technology, which is used in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as poor stability, and achieve stable structure and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a catalyst for steam reforming of methanol described in the above technical solution, comprising the following steps:

[0041] The soluble copper salt, the water-soluble salt corresponding to the oxide carrier, the fullerene C 60 mixed with water to obtain the first mixed solution;

[0042] Mixing the first mixed solution and the precipitant aqueous solution in parallel and aging to obtain a co-precipitate;

[0043]Calcining the co-precipitate to obtain the catalyst for hydrogen production by steam reforming of methanol.

[0044] In the present invention, unless otherwise specified, the raw materials used in the present invention are preferably commercially available products.

[0045] The present invention combines soluble copper salts, water-soluble salts corresponding to oxide carriers, fullerene C 60 Mix with water to obtain the first mixed solution.

[0046] In the present invention, the soluble copper ...

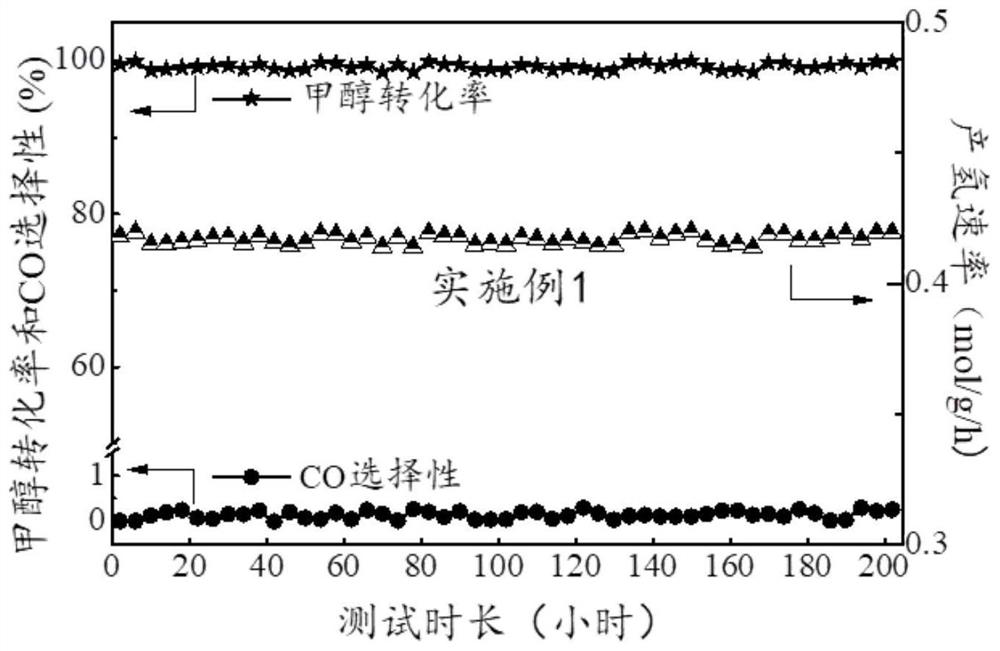

Embodiment 1

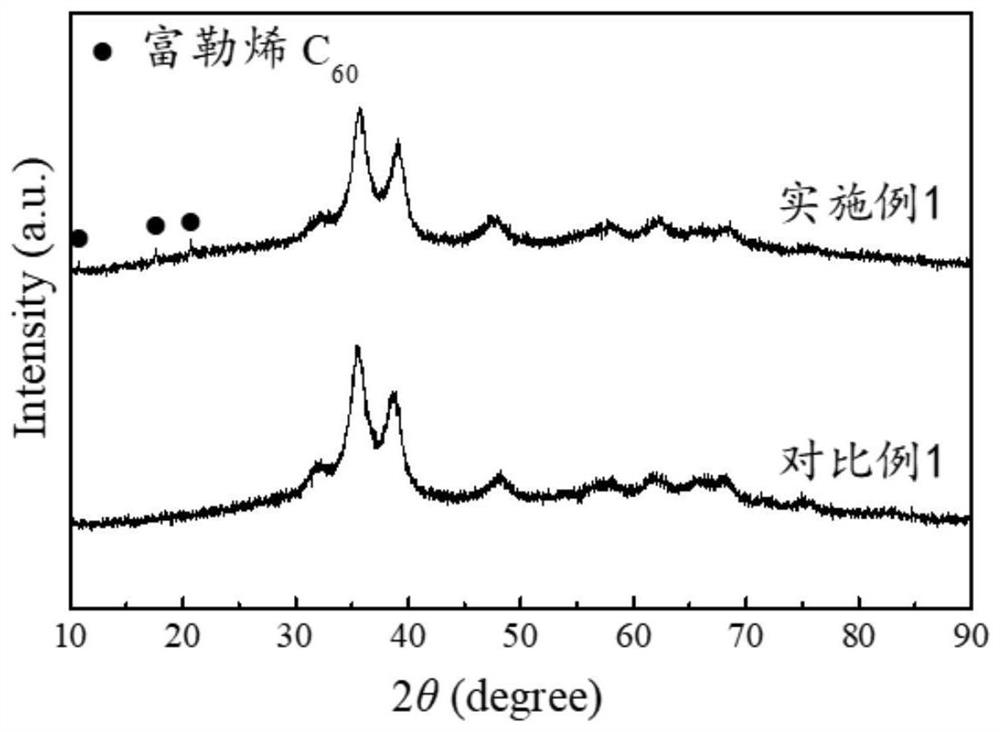

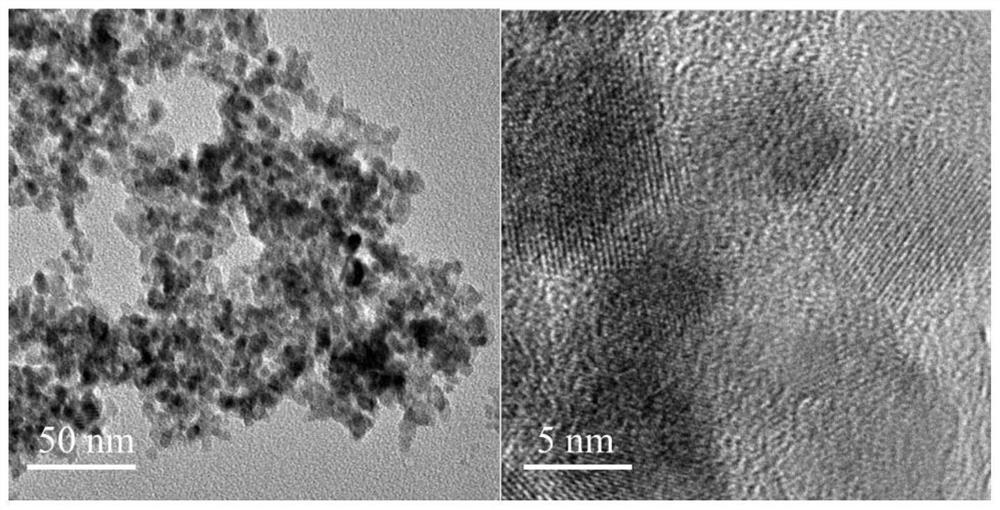

[0107] 4.56 g of copper nitrate trihydrate, 3.83 g of zinc nitrate hexahydrate and 3.31 g of aluminum nitrate nonahydrate were dissolved in 100 mL of deionized water to obtain a salt solution. 0.3g fullerene C 60 ultrasonically stirred in 25 mL deionized water to obtain C 60 Dispersion solution. Then the above two solutions were mixed and ultrasonically stirred to obtain the first mixed solution. The ultrasonic power is 40W, the stirring speed is 600r / min, and the ultrasonic stirring time is 30min. After configuring 125mL of 0.45mol / L sodium carbonate solution, add the sodium carbonate solution (6mL / min) and the first mixed solution (6mL / min) into the reactor in parallel, stir and age at 600r / min under heating at 60°C After 4 hours, the aging system was filtered at room temperature, and the filtered solid was washed twice with deionized water, then once with absolute ethanol, and then dried at 100°C for 12 hours after washing until neutral. A coprecipitate was obtained. T...

Embodiment 2

[0109] 4.56 g of copper nitrate trihydrate, 3.66 g of zirconium nitrate pentahydrate and 3.31 g of aluminum nitrate nonahydrate were dissolved in 100 mL of deionized water to obtain a salt solution. 0.3g fullerene C 60 ultrasonically stirred in 25 mL deionized water to obtain C 60 Dispersion solution. Then the above two solutions were mixed and ultrasonically stirred to obtain the first mixed solution. The ultrasonic power is 40W, the stirring speed is 600r / min, and the ultrasonic stirring time is 30min. After configuring 125mL of 0.45mol / L sodium carbonate solution, add the sodium carbonate solution (6mL / min) and the first mixed solution (6mL / min) into the reactor in parallel, stir and age at 600r / min under heating at 60°C After 4 hours, the aging system was filtered at room temperature, and the filtered solid was washed twice with deionized water, then once with absolute ethanol, and then dried at 100°C for 12 hours after washing until neutral. A coprecipitate was obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com